LED luminous element

A technology for light-emitting elements and light-emitting components, which is applied to semiconductor devices, light sources, point light sources, etc. of light-emitting elements, can solve the problems of affecting the quality of light sources or lamps, high manufacturing costs, and fragile structures, and expands the natural heat exchange function. , reduce glare, optimize the effect of the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

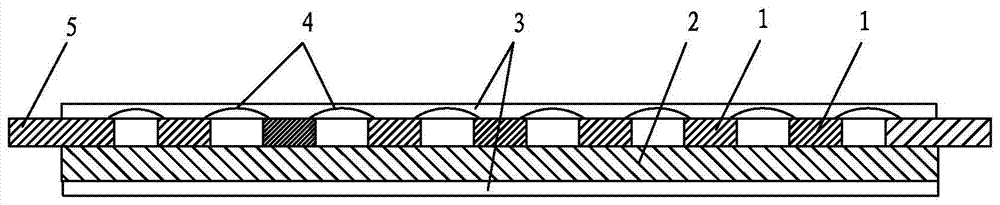

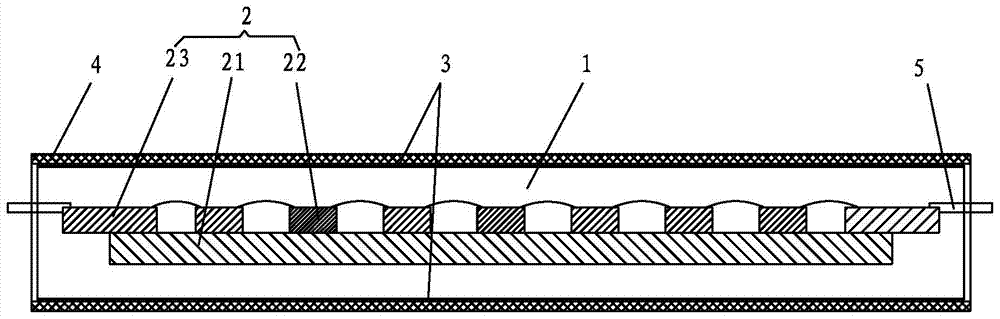

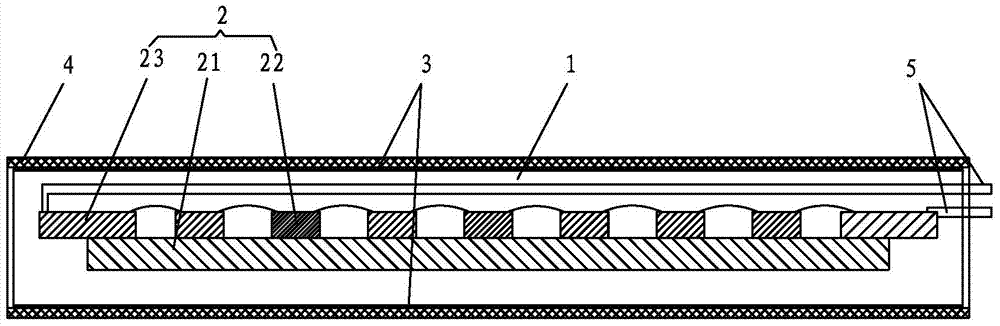

[0018] see figure 2 As shown, an LED light-emitting element according to the first embodiment of the present invention includes a heat-conducting transparent material 1 and a light-emitting assembly 2, and the light-emitting assembly 2 includes: a transparent support plate 21 and at least one LED chip 22 mounted on the transparent support plate 21 (There are a plurality of LED chips 22 in this embodiment, and connecting wires are provided between each LED chip), the light-emitting component 2 is provided with a power supply electrode 23, and the LED light-emitting element also includes phosphor powder 3 and a transparent casing 4, In this embodiment, the transparent casing 4 is a glass tube; the phosphor powder 3 is coated on the inner wall of the glass tube, so that the glare of the LED light-emitting element can be reduced, and a light and color effect with good consistency can be obtained; the light-emitting component 2 Placed in the glass tube, the two wires 5 connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com