Highly anti-torque drill rod

A drill pipe, high-resistance technology, applied in drill pipe, drill pipe, drilling equipment, etc., can solve the problems of drill pipe joint failure, drill pipe failure, low torsional strength of drill pipe, etc., to ensure safety and improve resistance. The effect of torsional strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

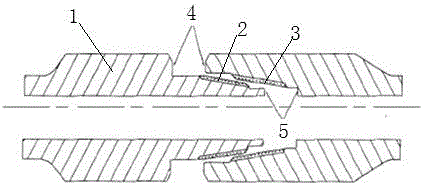

[0011] see figure 1 , the present invention relates to a high torsion-resistant drill pipe, comprising a drill pipe body 1, an external thread 2 is provided on the periphery of the small end of the pin of the drill pipe body 1, and an internal thread is provided on the inner wall of the large end of the box of the drill pipe body 1 3. The external threads 2 of two adjacent drill pipes mesh with the internal threads 3, so that the two drill pipes are connected, and the drill pipe body 1 has stepped surfaces at the upper and lower ends of the external thread 2 and the upper and lower ends of the internal thread 3, Wherein the step at the lower end of the external thread 2 and the lower end of the internal thread 3 is the main shoulder 4 , and the step at the upper end of the external thread 2 and the upper end of the internal thread 3 is the secondary shoulder 5 .

[0012] The main shoulder 4 and the auxiliary shoulder 5 form a double-shoulder structure, the main shoulder 4 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com