Method for collaborative governance of gas and coal spontaneous combustion of fully-mechanized caving face with single thick coal seam

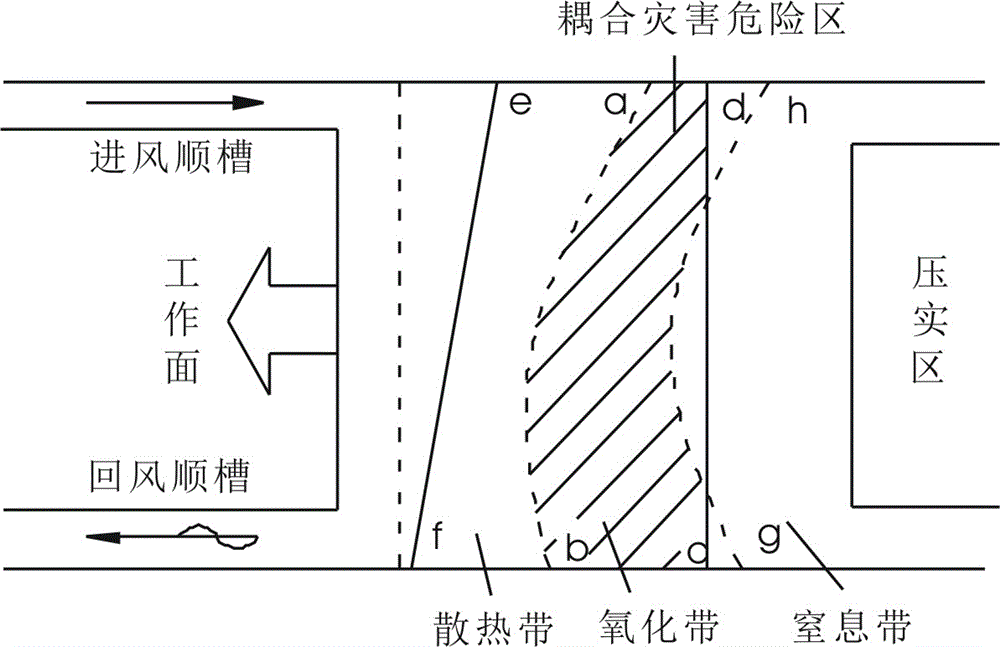

A fully mechanized caving face and working face technology, applied in the direction of gas discharge, ground mining, earthwork drilling, etc., can solve the problems of increasing the risk of gas explosion in the working face, affecting gas control, gas influx, etc., to prevent coupling disasters The danger of occurrence, the prevention of the danger of coal spontaneous combustion, and the effect of maintaining efficient and safe mining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

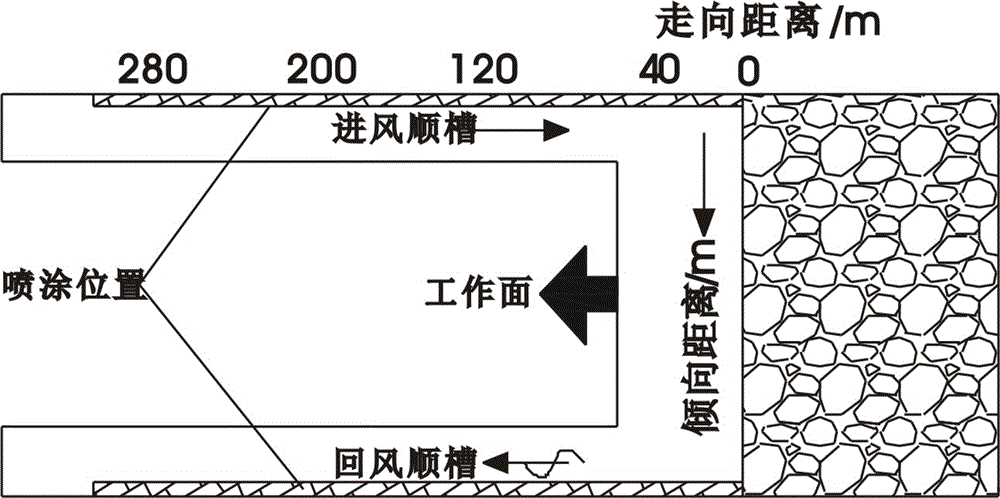

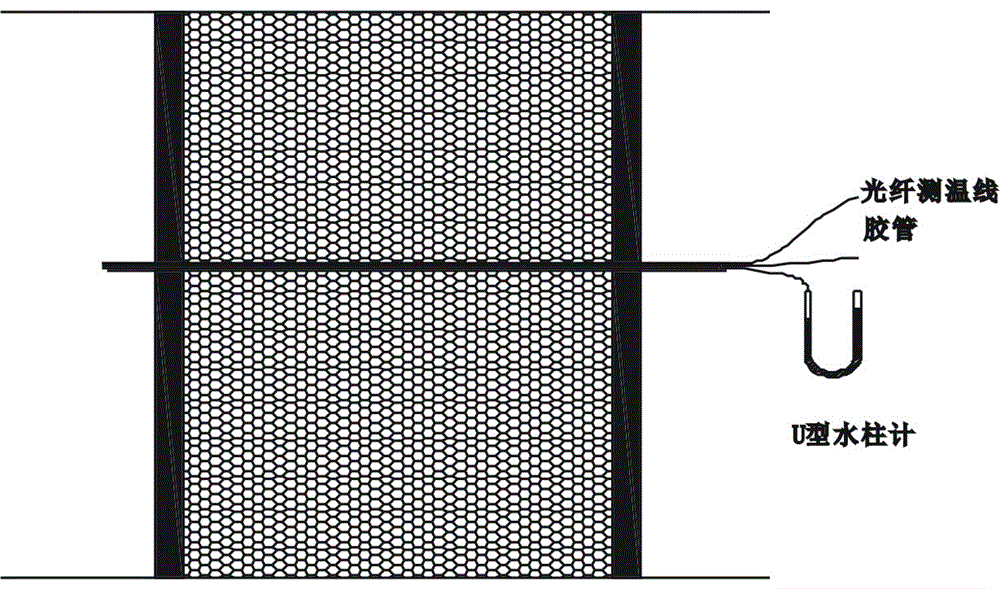

[0022] Now refer to the attached figure 2 , attached image 3 And attached Figure 4 Combined with Example 1, the description is as follows: the mining depth of a working face is -942.6-983.5 m, the working face length is 1596 m, the inclination length is 200 m, the mining coal thickness is 8.85-10.7 m, the average thickness is 9.6 m, and the average inclination angle is 4°. The mining height is 3 m, the average mining ratio is 1:2.2, the mining coal seam is a spontaneous combustion coal seam, and the ignition period is 69 to 169 days. The gas emission is large, and the gas emission is 1.3 m 3 / min, the depth of the working face is large, the ground pressure is large, the coal seam has a strong impact tendency, the roof and floor are medium-hard roofs, and has a weak impact tendency, the advance speed of the working face is slow in the early and late stages of mining, and the normal mining stage, the working face The gas concentration in the return air corner is maintained ...

Embodiment 2

[0026] Now refer to the attached figure 2 , attached image 3 And attached Figure 4 , illustrate as follows in conjunction with embodiment 2:

[0027] The design strike length of a certain working face is about 1400 m, the net length of the designed working face is 134.25 m, the thickness of the coal seam is 4.30-5.49 m, the average thickness is 4.60 m, the dip angle of the coal seam is 22-28°, the average dip angle is 25°, the recovery rate 85%. According to the general situation of the working face, combined with the prediction formula of the gas emission of the coal mining face, the relative gas emission of the working face is obtained as: 3.43 m 3 / t, and according to the daily output of the working face, the absolute gas emission of the working face is 7.62 m 3 / min, simply relying on ventilation methods cannot meet the requirements for gas disaster treatment.

[0028] According to the method for synergistic treatment of gas and coal spontaneous combustion in fully...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com