Two-position two-way turntable type switching valve

A two-position, two-way, turntable technology, applied in the direction of multi-way valves, valve devices, engine components, etc., can solve the problems of complex structure, difficult processing and sealing of two-position, two-way switching valves, and meet application requirements and The effect of broad industrialization prospect, compact structure and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Further description will be given below through specific embodiments and in conjunction with the accompanying drawings.

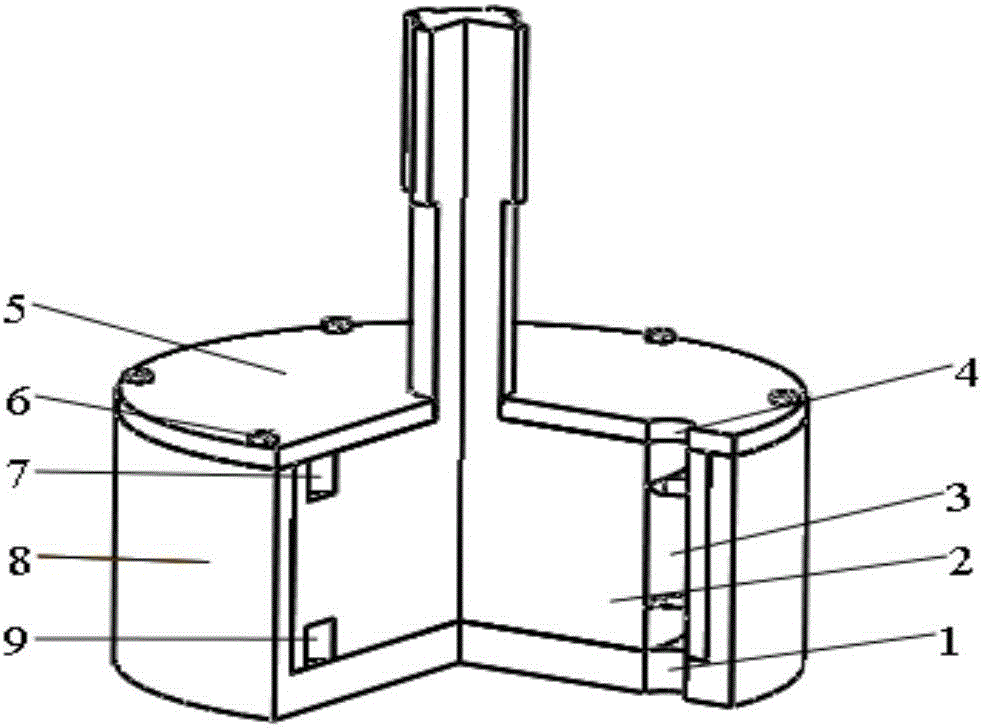

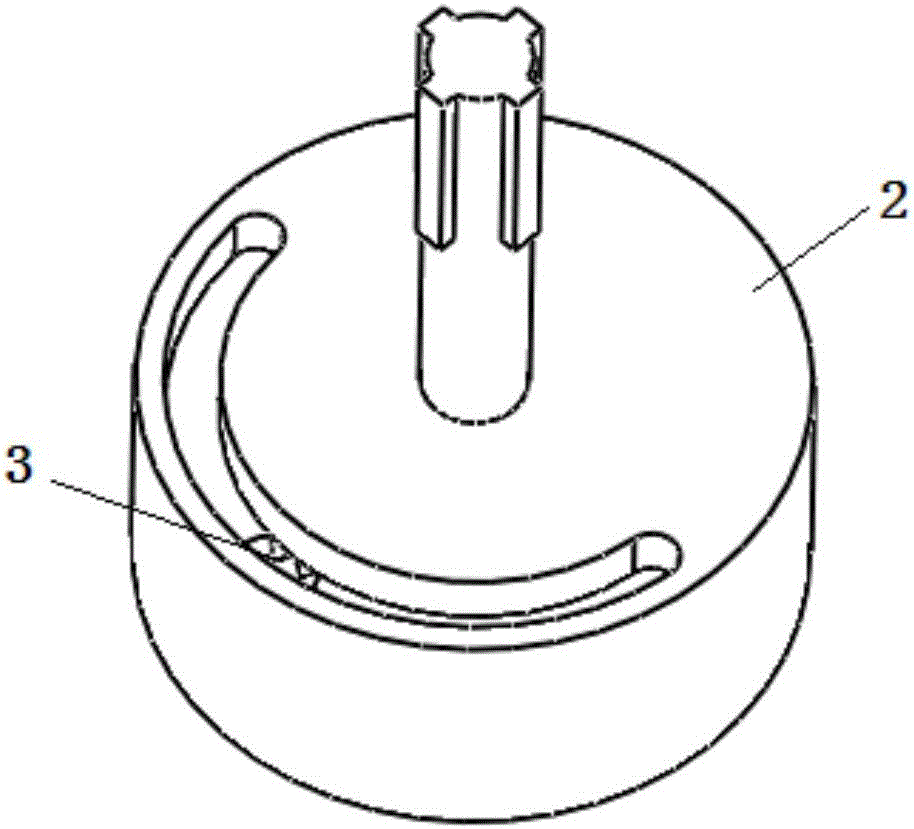

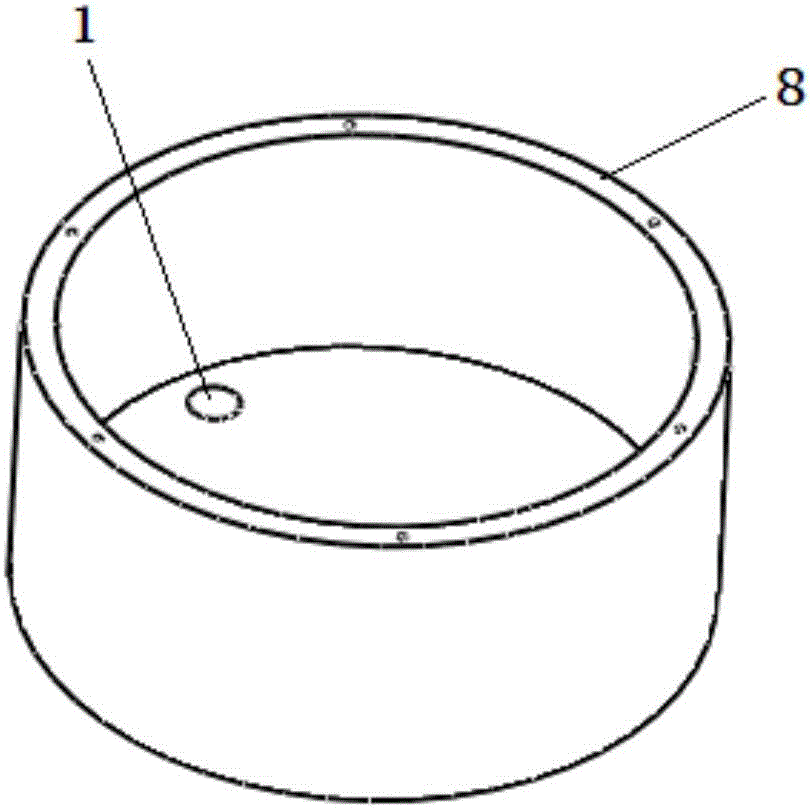

[0013] The main structure of the present invention includes a valve body 8, a turntable 2, and an end cover 5. The valve body 8 is fixed on the base, and the inside of the valve body 8 is a cylindrical cavity. Or the flange is connected with the oil outlet pipeline. The end cover 5 is disc-shaped, with an oil inlet 4 formed on it, and the axis of the oil inlet 4 coincides with the oil outlet 1; the end cover 5 and the upper surface of the valve body 8 are connected by bolts 6, and the connecting surface has good sealing performance. Can not allow oil leakage in the valve body, generally six connecting bolts 6 are used. The turntable 2 is installed in the cylindrical cavity formed by the valve body 8 and the end cover 5. One end of the turntable 2 has a rotating shaft protruding from the center opening of the end cover 5. The shaft end has a key for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com