Open accessory with spring tension

A technology of mounting parts and spring parts, applied in the direction of pipe components, pipes/pipe joints/fittings, pipe supports, etc., which can solve the problems of scattered errors of line compression rings, inability to guarantee functions (damping or isolation, difficult installation, etc.)

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

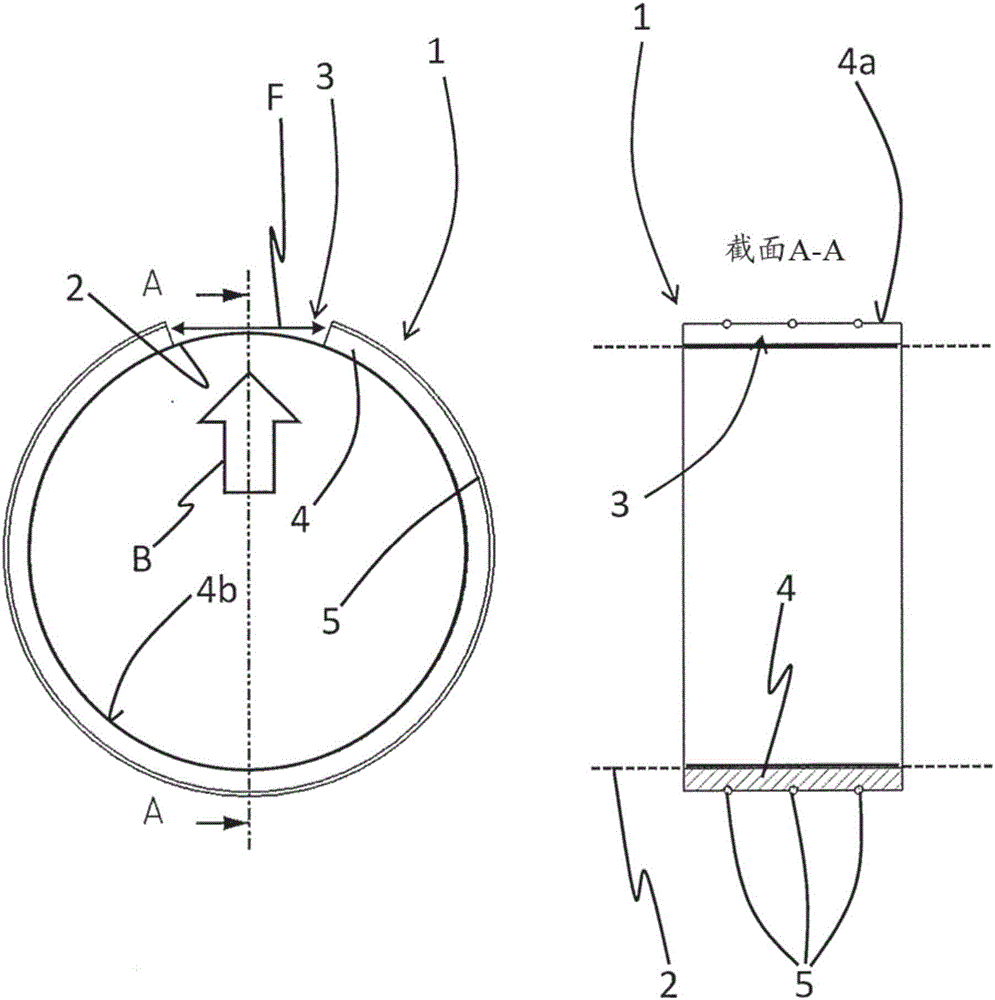

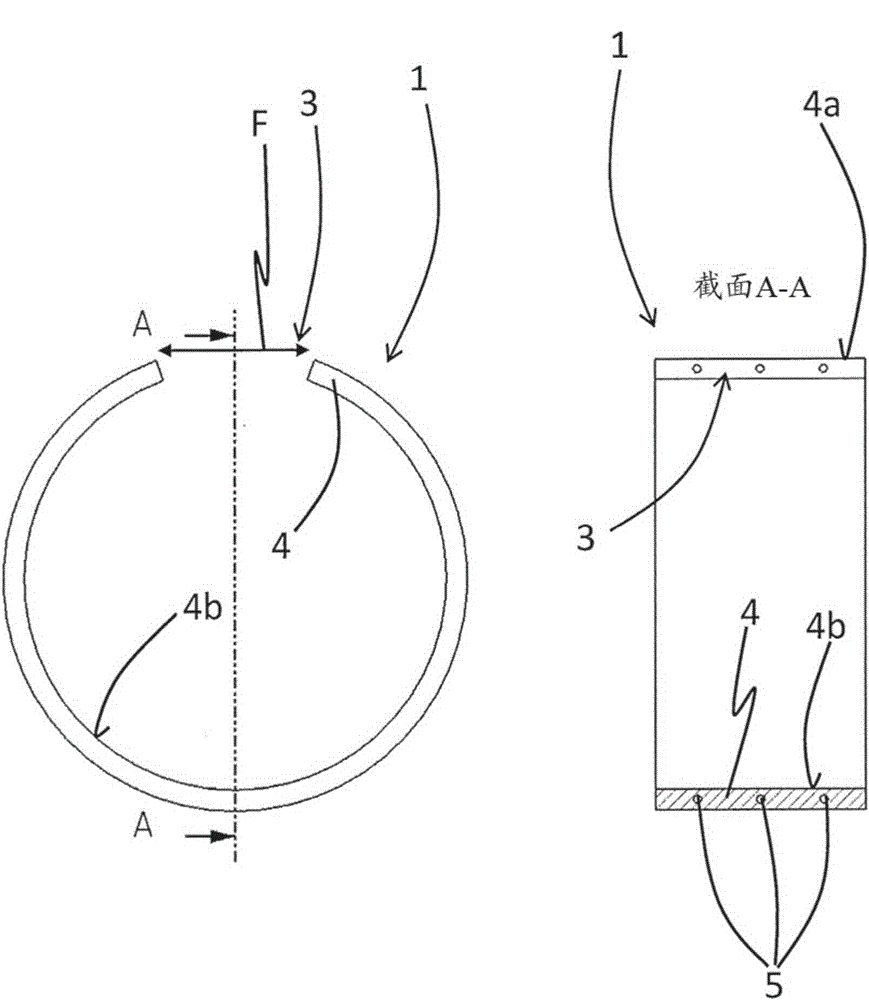

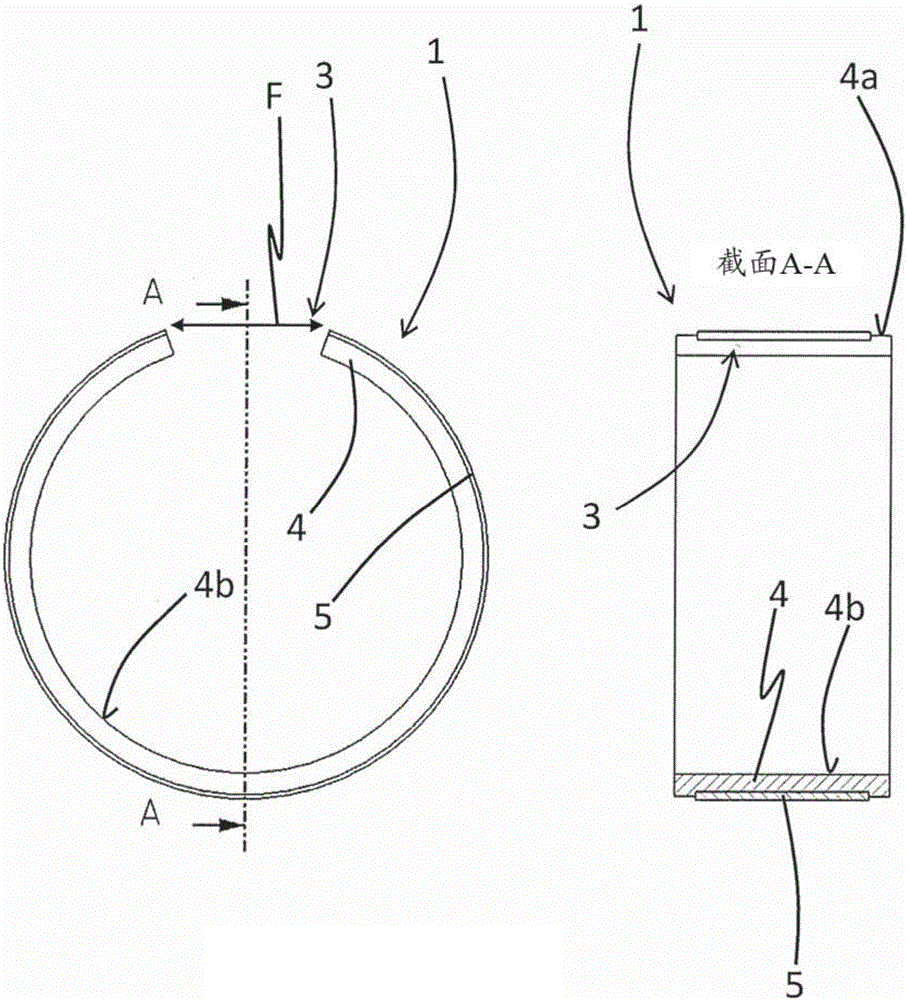

[0048] in figure 1 The mounting member 1 of the present invention is shown in the state where it is installed on the pipeline 2. In the view part on the left, the front view shows the arrangement structure; in the right part, the arrangement structure is shown in a longitudinal sectional view along the line A-A in the view part on the left. The pipe 2 has a circular cross section in the illustrated embodiment and can be constructed in the form of a corrugated pipe or a hose or in the form of a corrugated sleeve. figure 1 Is not explicitly shown in. In addition, it is considered that the pipeline 2 only has a crooked portion locally.

[0049] The mounting part 1 is formed in the form of a ring, which has a notch at the reference number 3. The mounting member 1 includes a main body denoted by the reference numeral 4, and on its outer surface 4a, the main body has three spring members in the form of annular springs arranged in parallel and equidistant from each other. figure 1 It i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com