Double-purpose double-stage electronic scale

A technology of electronic scales and loading boards, which is applied in the field of structural design of electronic scales, can solve the problems of using, being expensive, and not being able to be used for other purposes, and achieve the effects of preventing damage, being easy to popularize, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] (buy Example 1)

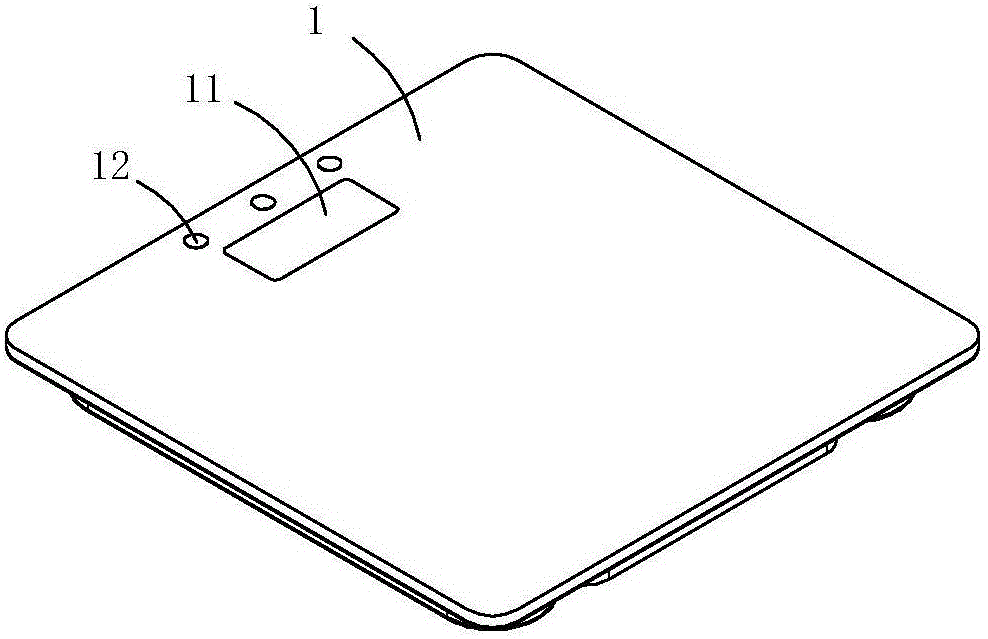

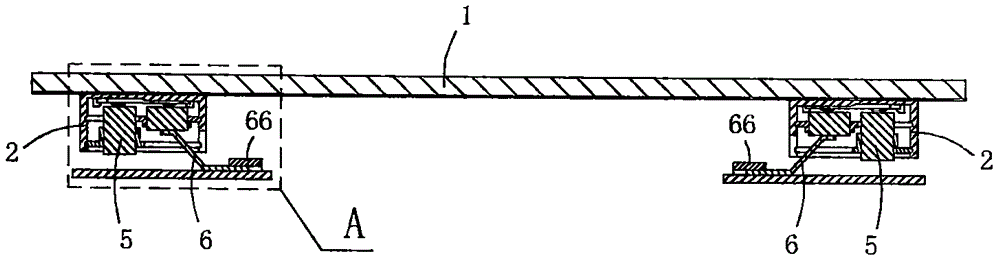

[0015] The present embodiment is a dual-purpose two-stage electronic scale, see Figure 1 to Figure 7 As shown, it includes a loading plate 1, a display screen 11, an adjustment switch 12, and four load cell assemblies 2 for weighing the load on the loading plate; the shape of the loading plate in this embodiment is square, and the Made of glass or fiberglass; four load cell assemblies are evenly distributed at the four corners of the bottom wall of the loading plate.

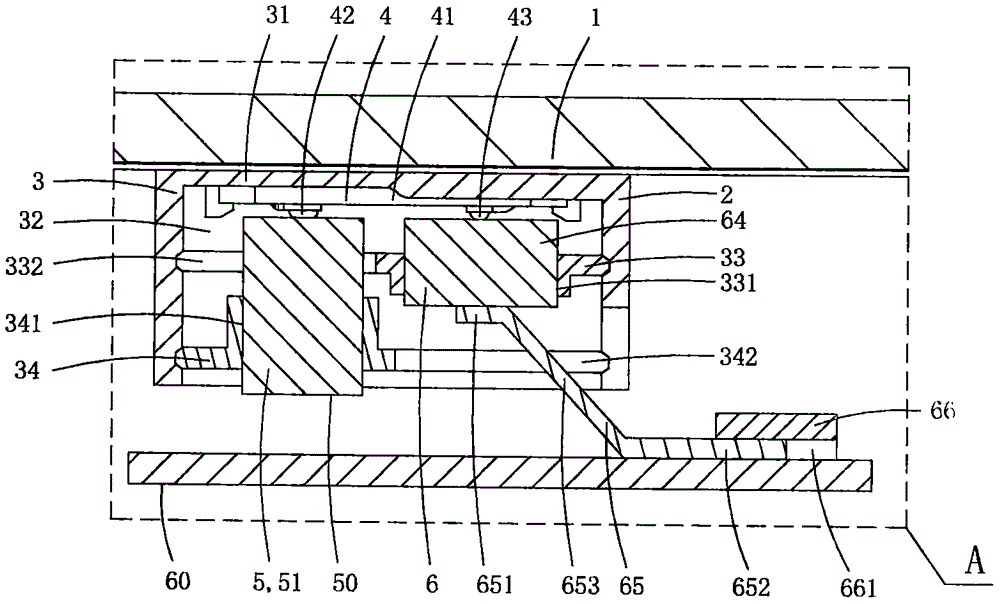

[0016] In this embodiment, each load cell assembly includes a plastic base 3 , a load cell 4 , a first support foot 5 with a first supporting portion 50 and a second support foot 6 with a second support portion 60 .

[0017] see Figure 5 to Figure 7 As shown, the load cell 4 in this embodiment is the same as that in Embodiment 1, including a fixed part 41, a first precision elastic bearing part 42, a second precision elastic bearing part 43, and a first precision elastic bearing part...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap