Ash fusibility tester and image taking method thereof

A kind of technology of ash fusion tester, which is applied in the field of ash fusion tester and its imaging, can solve the problems of low test efficiency of ash fusion tester and complex design of furnace tube, so as to improve sample test efficiency and energy The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

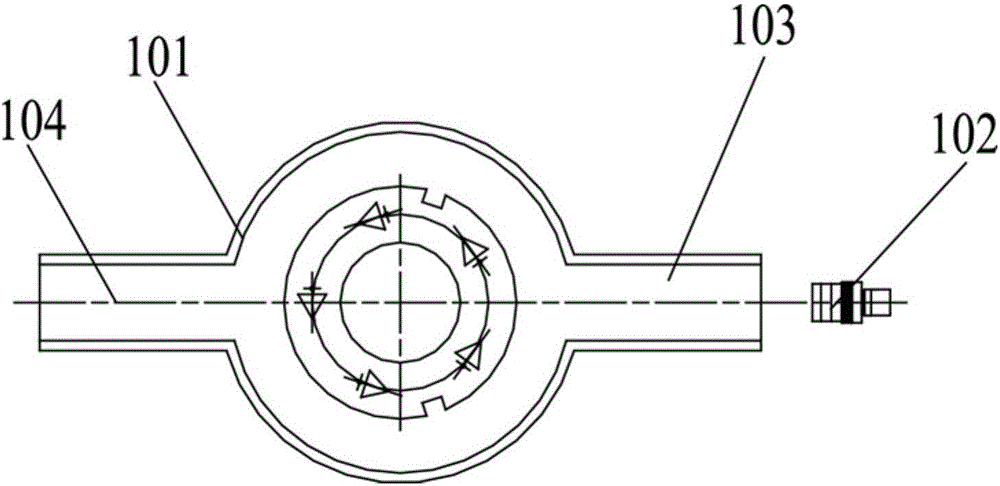

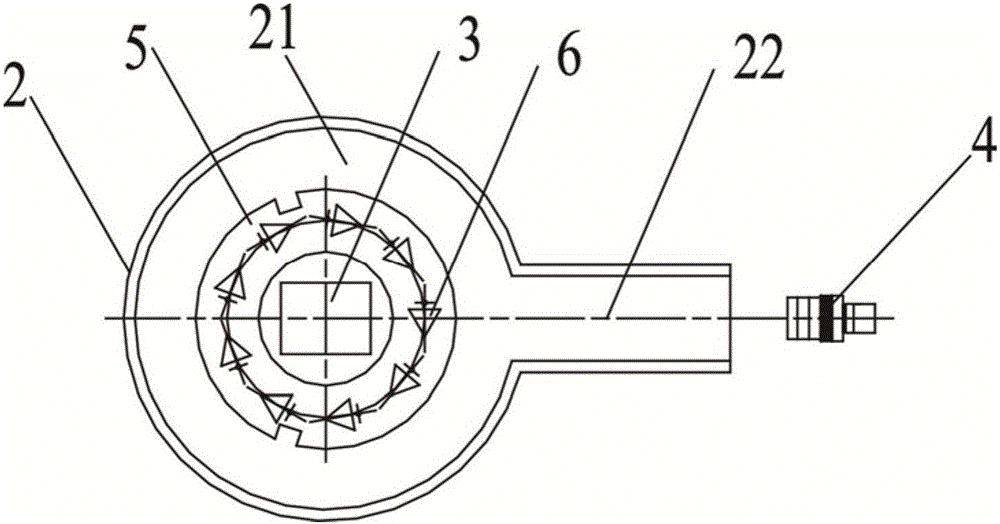

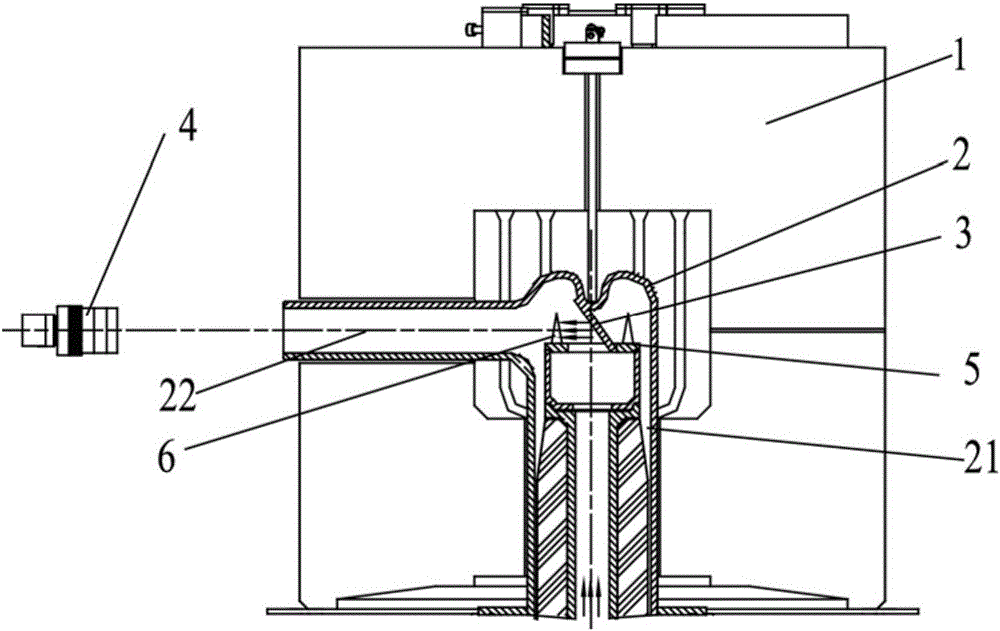

[0031] Such as figure 2 and image 3 As shown, an ash fusion tester provided by an embodiment of the present invention includes a high-temperature furnace 1, a furnace tube 2, a background plate 3, an imaging assembly 4 and a disc-shaped ash cone support plate 5 The furnace tube 2 is set in the high temperature furnace 1, the ash cone supporting plate 5 is set in the furnace tube 2, and the bottom of the ash cone supporting plate 5 is provided with a rotating mechanism for driving the ash cone supporting plate 5 to rotate in the furnace tube 2. The image taking assembly 4 is used to obtain the image of the ash cone 6 on the ash cone support plate 5 . Specifically, the furnace tube 2 includes an ash cone cavity 21 and an imaging cavity 22 arranged vertically to the ash cone cavity 21 . The ash cone supporting plate 5 is arranged in the ash cone cavity 21, and the image of the ash cone 6 in the ash cone cavity 21 reaches the image pickup assembly 4 through the imaging cavity ...

Embodiment 3

[0040] This embodiment provides a method for taking images of the ash fusion tester of Embodiment 1, comprising the following steps:

[0041] S1, the light in the low temperature area is incident on the background plate 3 to form a dark reflective surface;

[0042] S2, driving the ash cone supporting plate 5 to rotate;

[0043] S3 , the imaging assembly 4 photographs the ash cone 7 located between the background plate 3 and the imaging assembly 4 .

Embodiment 4

[0045] The present embodiment provides a kind of imaging method of the ash fusion tester of embodiment 2, comprises the following steps:

[0046] S1, the light in the low temperature area is incident on the background plate 3 to form a dark reflective surface;

[0047] S2, driving the ash cone supporting plate 5 to rotate;

[0048] S3, the imaging assembly 4 photographs the ash cone 7 located between the background plate 3 and the low temperature area according to the light reflected by the background plate 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com