Water resistance load device and control method thereof

A load device and load control technology, which is applied in the direction of motor generator testing, etc., can solve problems such as easy boiling, increased ship construction costs, and difficult stability of experimental loads, so as to reduce workload, solve unstable experimental results, and improve work efficiency. and reliability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

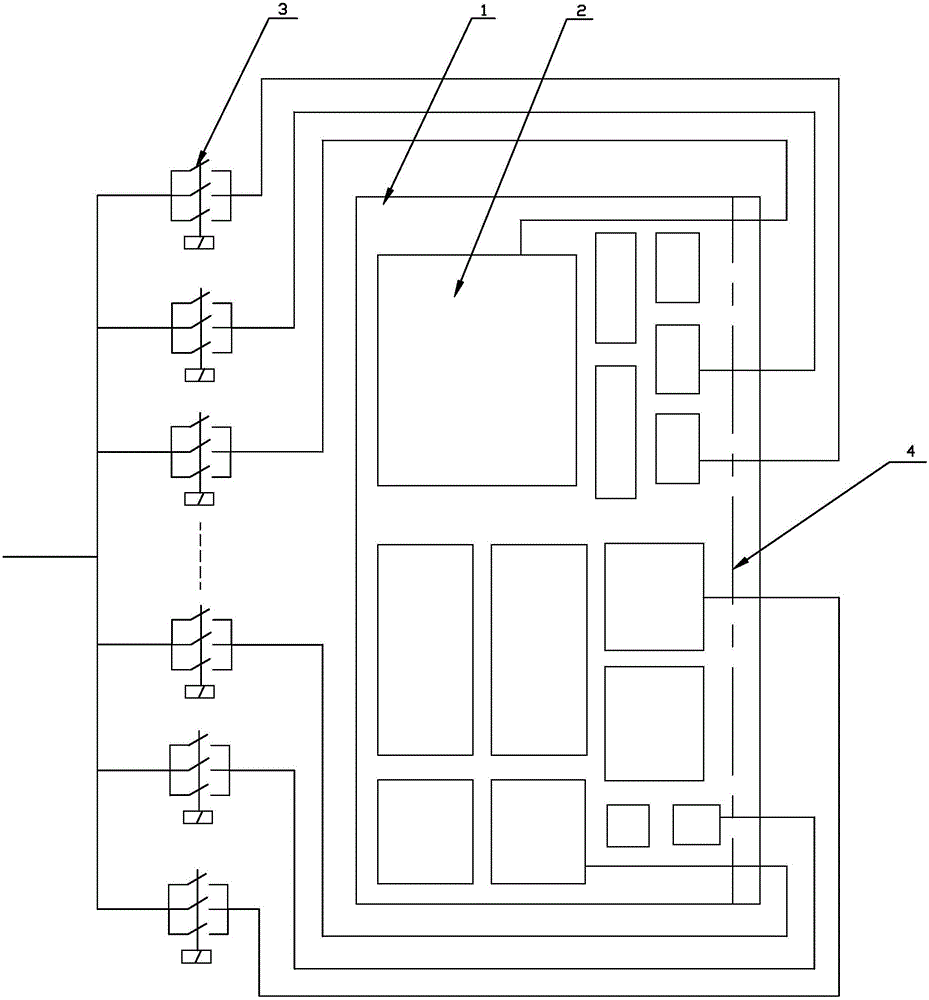

[0016] refer to figure 1 , the present invention is a water resistance load device, comprising a pool body 1 and several load plates 2 separated from each other in the pool body 1, a conductive liquid 4 is provided in the pool body 1, and each load plate 2 is completely immersed in the conductive liquid 4 Among them, each load plate 2 is connected to a switch 3 respectively, and the other ends of each switch 3 are connected together.

[0017] A water resistance load control method, comprising the following steps:

[0018] 1) Number the load plates 2 connected to a switch 3 and immerse them in the conductive liquid 4 of the cell body 1;

[0019] 2) Determine the total area of the required load plate 2 according to the water resistance load required by the experiment and the concentration of the conductive liquid 4, and determine each load plate 2 that needs to be connected to the power supply according to the total area of the required load plate 2 number of

[0020] 3) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com