Side gating hot runner apparatus with continuous valve pin movement

A technology of hot runner and injection equipment, applied in the field of electric actuators, can solve the problems of not being configured to prevent the displacement of the mold core, unable to balance the flow of the mold, not configured to balance the flow of the mold, etc., to achieve the effect of preventing the displacement of the mold core

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

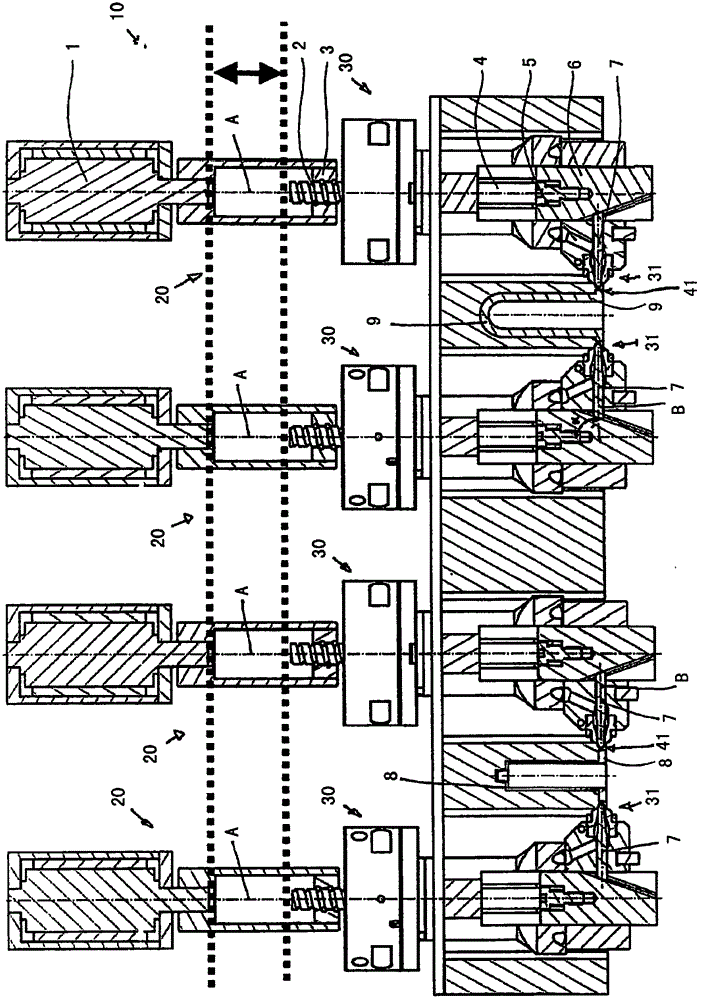

[0031] figure 1 A hot runner injection molding apparatus is shown with four electric actuators 20 and four side pouring hot runner nozzles 30 . Each nozzle 30 comprises a valve gate 31 with a valve pin 7 for closing a communication opening 41 in the mold cavity 8, 9; a valve pin actuating means 6 connected to at least one valve pin 7, which movable back and forth along a first axis A, whereby at least one valve pin 7 is movable along a second axis B, which is arranged at an angle α with respect to the first axis A; and the electric actuator 1, Used to drive the valve pin actuator 6.

[0032] The mold cavities 8, 9 are arranged in a platen of the injection molding machine. All four electric actuators 20 are in a position in which the valve pin 7 , whose end has a cylindrical shape, is in the closed position. The corresponding positions of the valve pin drives 2 , 3 are indicated by parallel dashed lines.

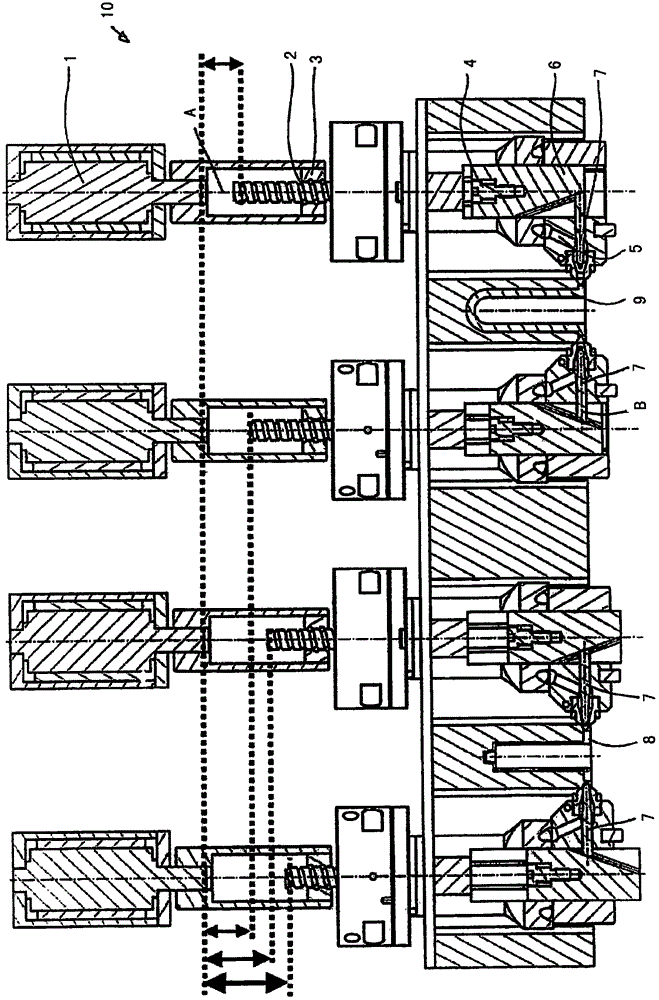

[0033] figure 2 Shows figure 1 In the hot runner injection moldin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com