Mold for spigot or muzzle bell of HDPE hollow wall winding pipe

A winding pipe and mold technology, applied in the mold field of HDPE hollow wall winding pipe socket or socket, can solve the problems of high cost, no socket or socket, complex construction, etc., to improve the compression resistance and facilitate placement and installation , Easy demoulding and the effect of pipe socket connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

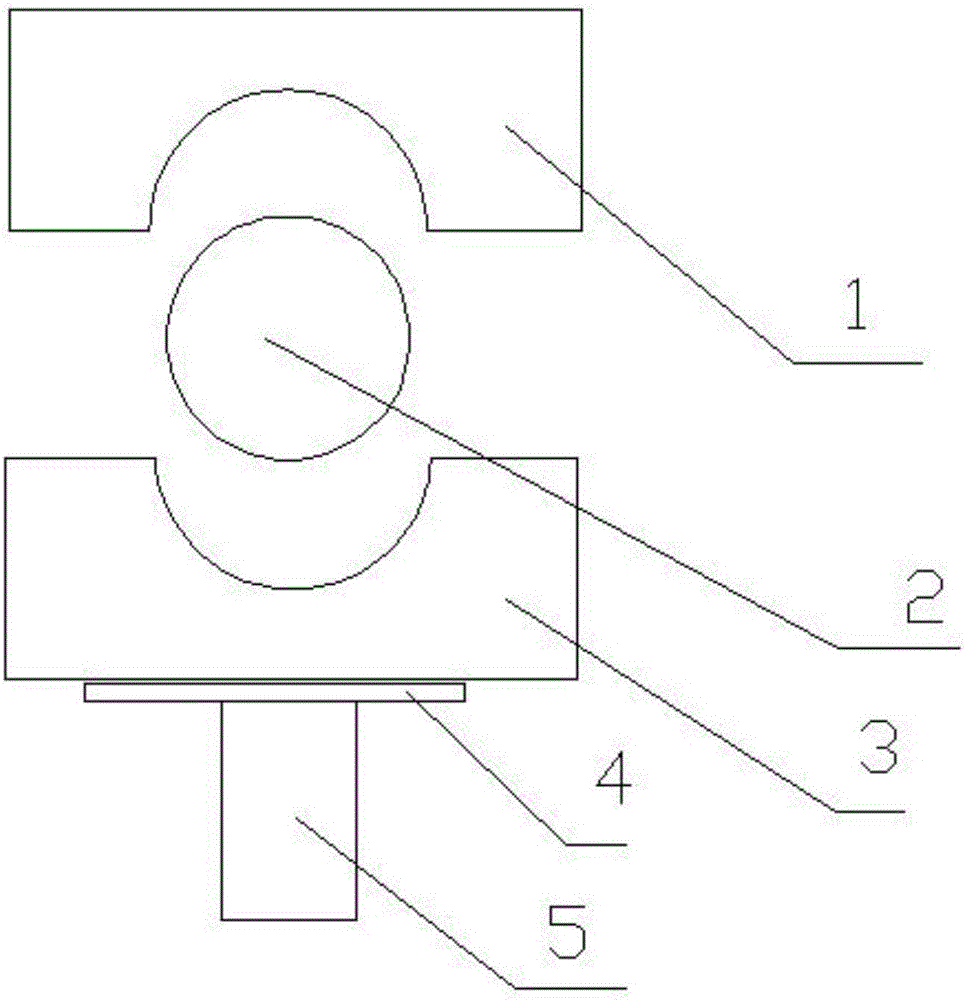

[0015] see figure 1 , is a structural schematic diagram of a specific embodiment of the present invention.

[0016] A mold for the socket or socket of HDPE hollow wall winding pipe, comprising a lower mold horizontally arranged on the ground, a mold core 2 is arranged horizontally above the lower mold, an upper mold 1 is arranged above the mold core, and the lower mold The top is provided with a lower semicircular groove, the upper mold is provided with an upper semicircular groove, and the lower semicircular groove and the upper semicircular groove form a circular hole matching the mold core; a positioning support is arranged horizontally and coaxially above the lower mold. The positioning support is a ring, and one end of the positioning support shrinks inward, and the shape is a cone. The positioning support is coaxially provided with a cylindrical cavity for the mold core; the lower mold includes a lower mold body 3 With the base 5, the side wall of the base is perforated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com