On-line real-time torque optimal distribution control method of distributed driving electric automobile

A technology for optimizing distribution of electric vehicles, applied in the direction of electric vehicles, control drives, control devices, etc., can solve problems such as large deviations, meet the needs of vehicle operation, reduce system power consumption, and achieve the effect of total energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

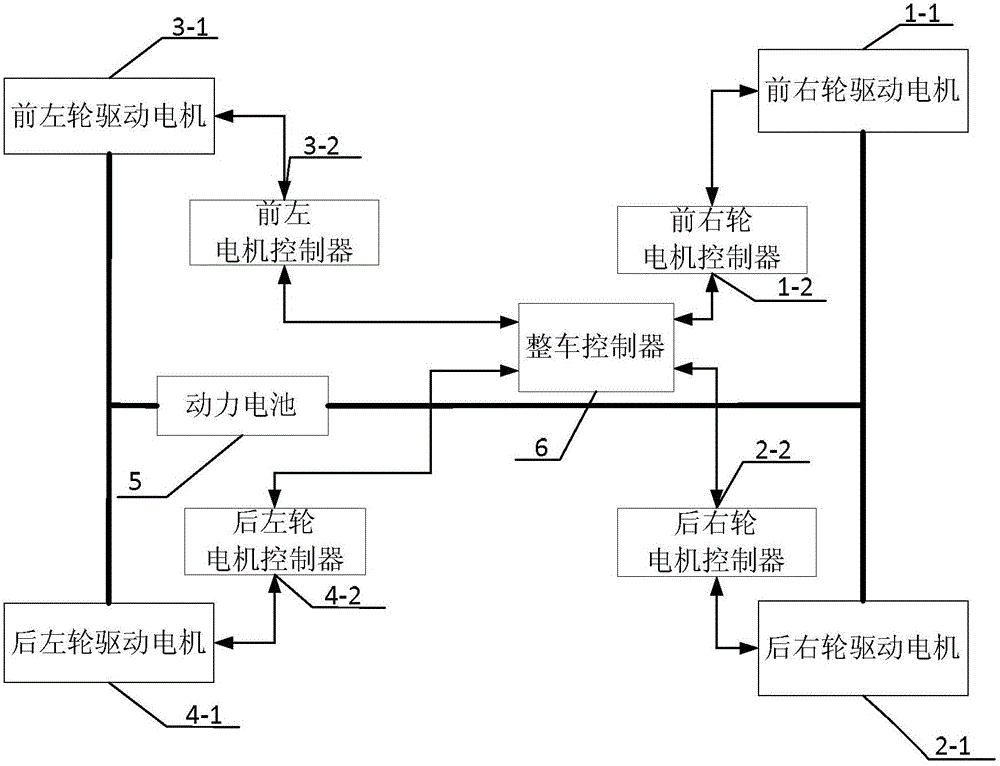

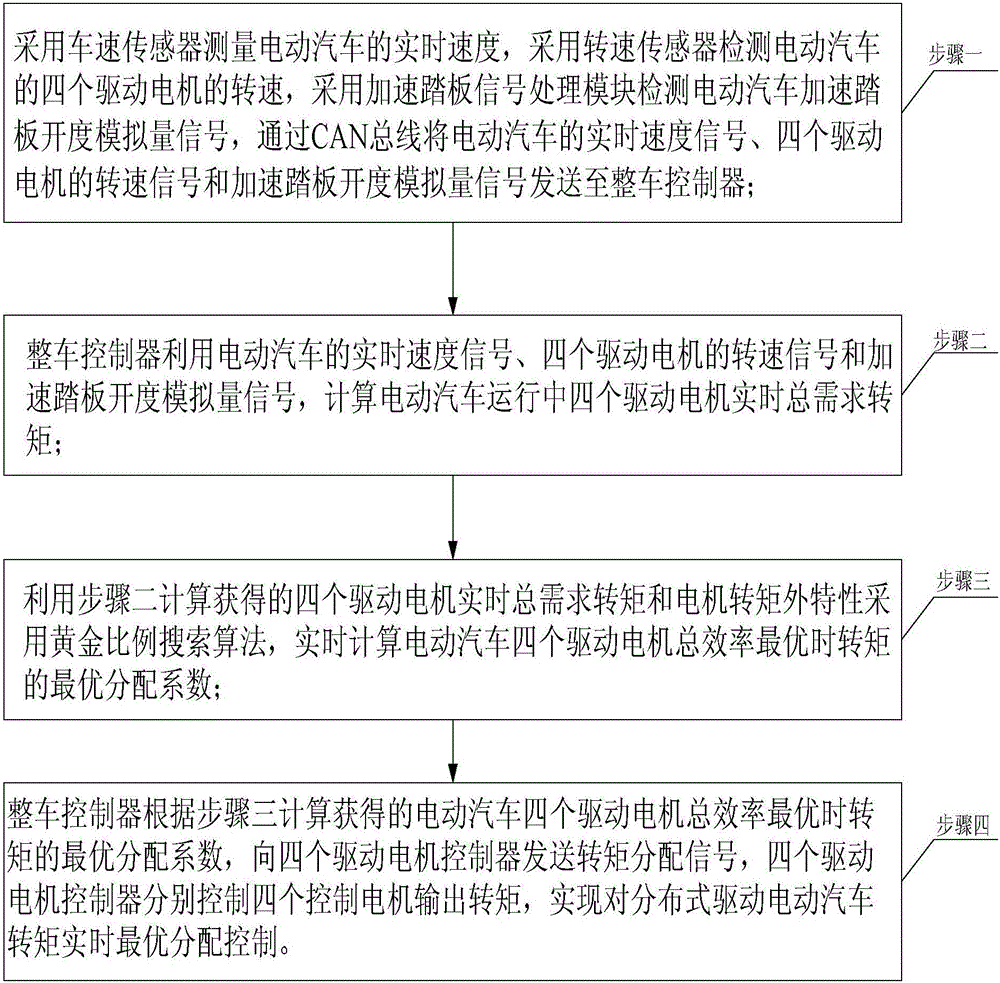

[0022] Specific implementation mode 1. Combination figure 1 and figure 2 Describe this embodiment, a distributed drive electric vehicle online real-time torque optimal allocation control method described in this embodiment, the method is realized based on the distributed drive electric vehicle online real-time torque optimal distribution control device, the device includes four Drive motor, four drive motor controllers, power battery pack 5 and vehicle controller 6;

[0023] The four drive motors are: front right wheel drive motor 1-1, rear right wheel drive motor 2-1, front left wheel drive motor 3-1 and rear left wheel drive motor 4-1;

[0024] The four drive motor controllers are: front right wheel motor controller 1-2, rear right wheel motor controller 2-2, front left wheel motor controller 3-2 and rear left wheel motor controller 4-2;

[0025] The drive signal input state signal output end of the front right wheel drive motor 1-1 is connected to the drive signal output...

specific Embodiment approach 2

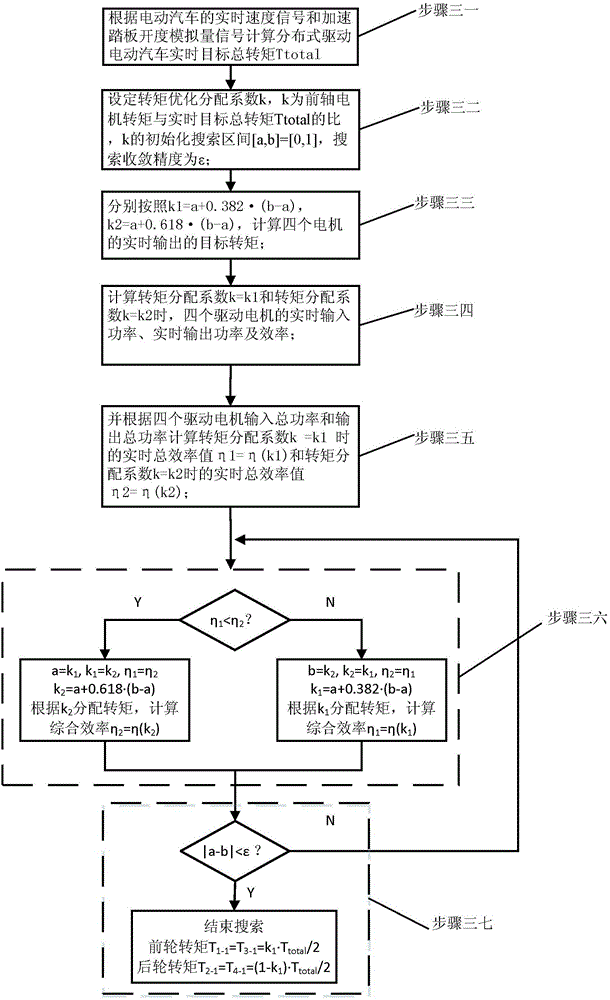

[0036] Specific embodiment two, combine image 3Describe this embodiment. This embodiment is a further description of a distributed drive electric vehicle online real-time torque optimization distribution control method described in the first specific embodiment. The real-time total demand torque of the motor and the external characteristics of the motor torque use the golden ratio search algorithm to calculate the optimal distribution coefficient of the torque of the four driving motors of the electric vehicle in real time; the specific steps are:

[0037] Step 31. Calculate the real-time target total torque Ttotal of the distributed drive electric vehicle according to the real-time speed signal of the electric vehicle and the analog signal of the accelerator pedal opening;

[0038] Step 32: Set the torque optimization distribution coefficient k, k is the ratio of the front axle motor torque to the real-time target total torque Ttotal, the initialization search interval of k ...

specific Embodiment approach 3

[0049] Specific embodiment 3. This embodiment is a further description of the online real-time torque optimization distribution control method for distributed drive electric vehicles described in specific embodiment 1. Steps 3 and 5 are based on the input total power and output total The concrete method of calculating the real-time total efficiency value η1=η(k1) when the torque distribution coefficient k=k1 and the real-time total efficiency value η2=η(k2) when the torque distribution coefficient k=k1 is as follows:

[0050] By formula:

[0051] P i n , 1 ( i ) = U 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com