A light-shielding paper separating device

A separation device and shading paper technology, applied in the direction of pile separation, object separation, transportation and packaging, etc., can solve the problems of high cost, multiple models cannot be shared, and high precision requirements of special trays, and achieve the goal of improving layering efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

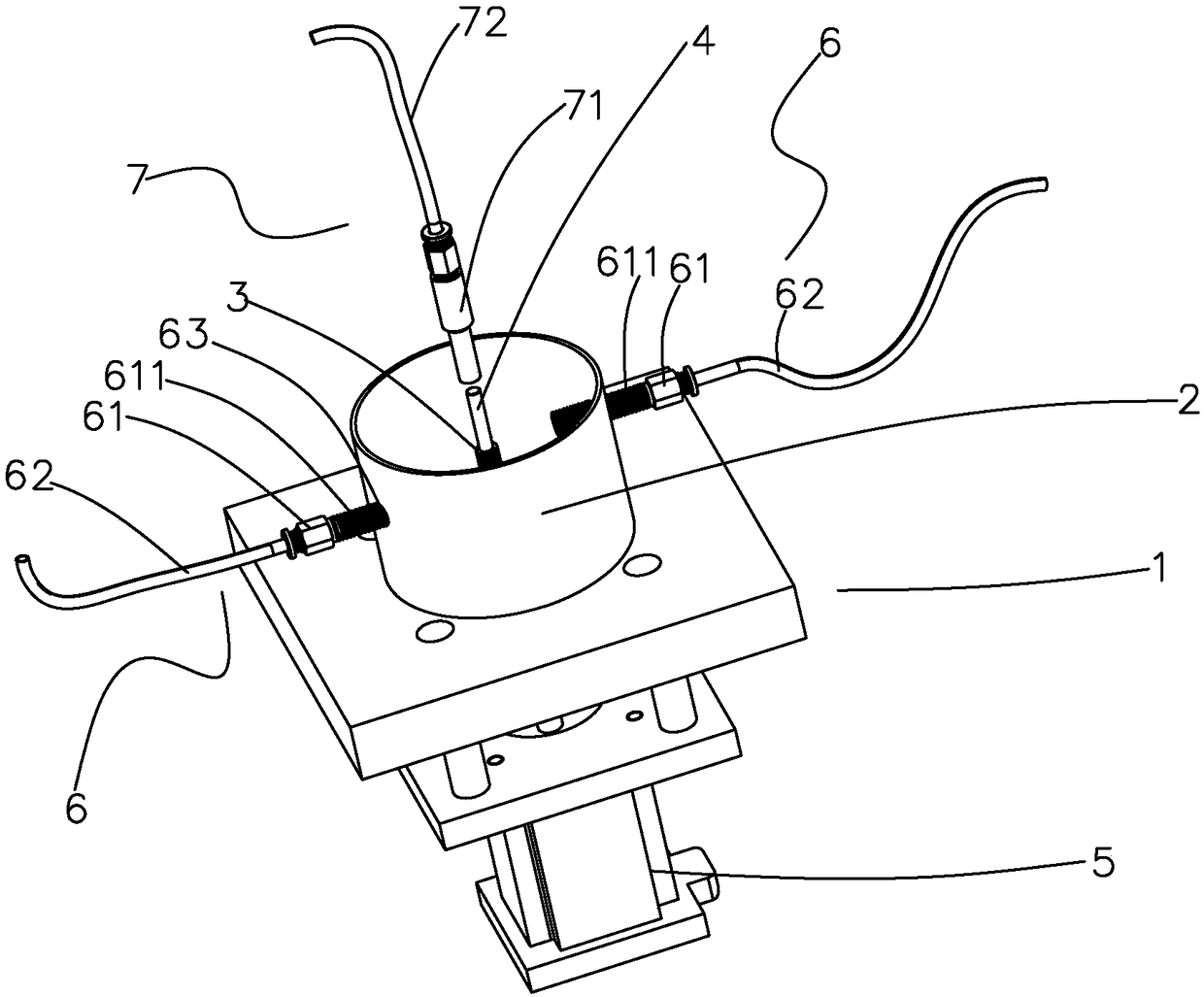

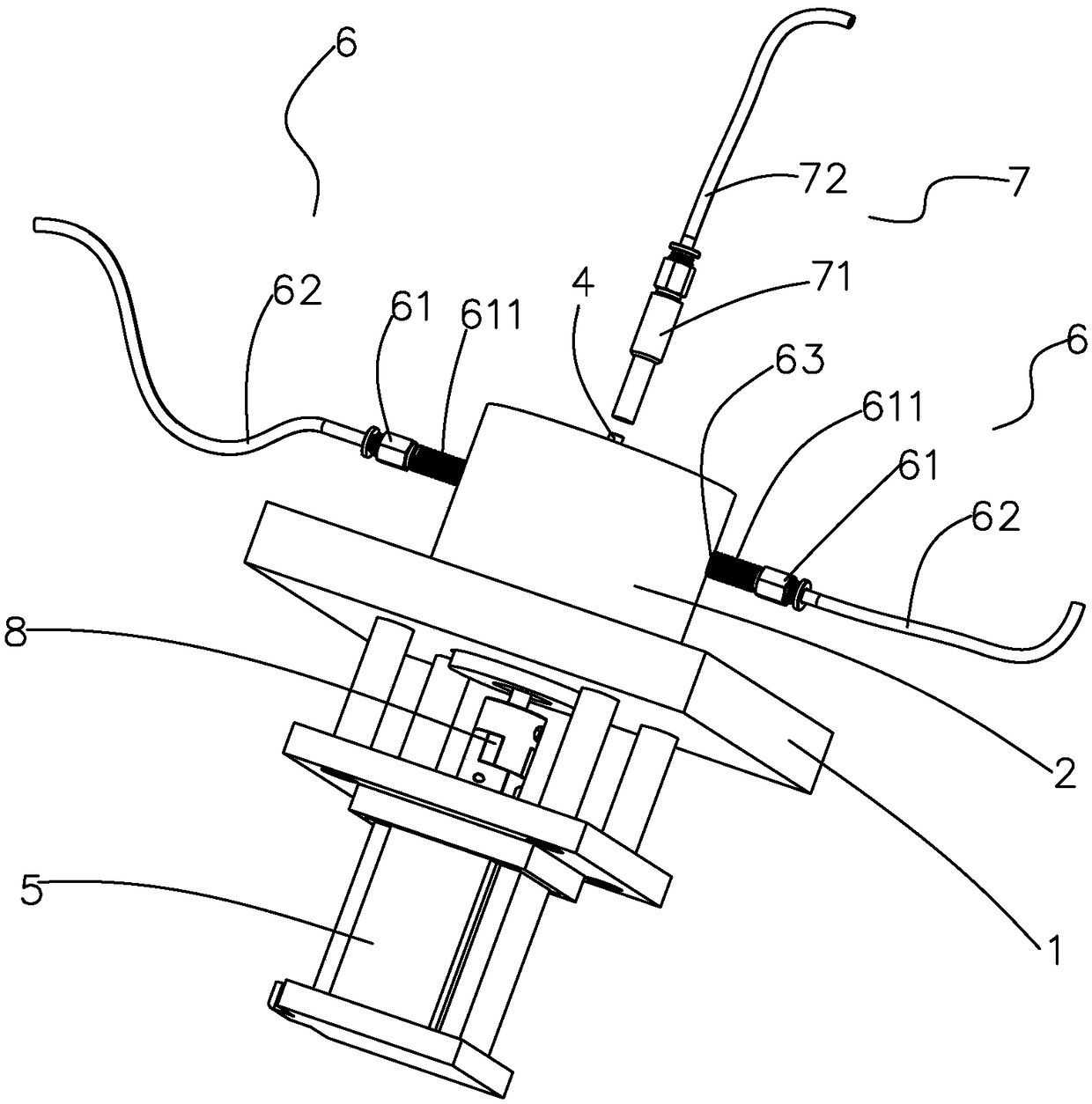

[0022] like figure 1 and figure 2 As shown, a light-shielding paper separation device of the present invention includes a connecting seat 1, a cylindrical tube 2 with an open end is fixed on the connecting seat 1, and the connecting seat 1 and located in the cylindrical tube 2 are rotatably connected to guide The guide shaft 4 of the shading paper 3 is stacked, the connecting seat 1 is fixed with a drive motor 5 for driving the guide shaft 4 to rotate, and the side wall of the cylinder 2 is provided with an air nozzle assembly for blowing air to the guide shaft 4 6. A suction pen assembly 7 for sucking up the light-shielding paper 3 is arranged above the guide shaft 4 . When working, the drive motor 5 rotates, the guide shaft 4 rotates accordingly, and the shading paper 3 stacked on the guide shaft 4 rotates correspondingly, and the upper part is lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com