A flexible air chamber jig system and layering method for particle swirl layering

An air chamber and jig technology, which is applied in coal sorting, ultra-pure coal preparation, underground gangue discharge, flexible air chamber jig system and layering, can solve the problem of limited particle pulsation and low separation efficiency To achieve the effect of strengthening particle pulsation amplitude, improving sorting efficiency and reducing flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In the following, the embodiments of the present invention will be described in detail with reference to the accompanying drawings.

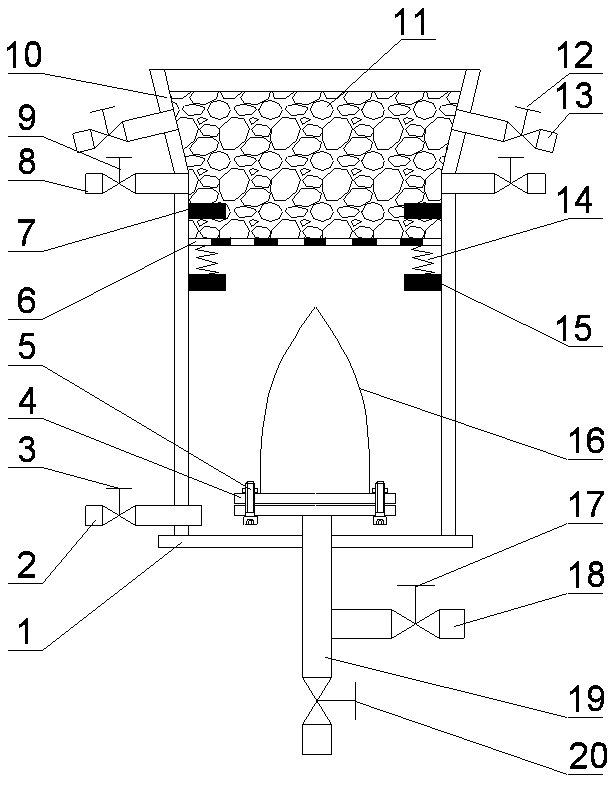

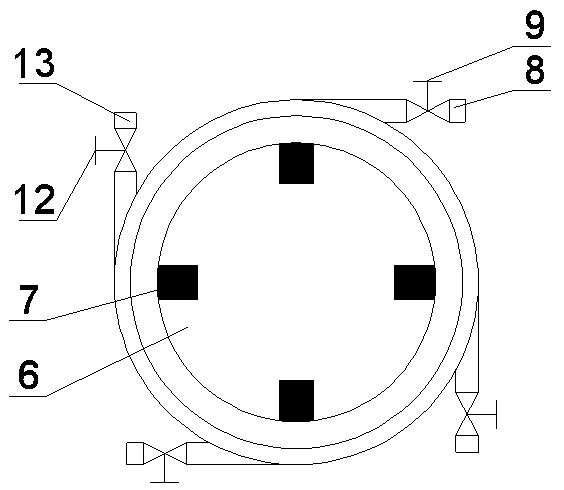

[0019] A flexible air chamber jig system with particle swirling and layering, as attached figure 1 and figure 2 shown. In this device, the water inlet 2 and the water inlet valve 3 are installed on the jig machine body 1 first; the air bag 16 is fixed at the corresponding position by the bolt 5 and the connecting flange 4, and then the support seat 15 and the support seat 15 are installed on the inner wall of the body 1. The spring 14 is compressed, and the sieve plate 6 is fixed on the spring 14 . In order to ensure the stable pulsation of the sieve plate 6, the limiter 7 is installed on the inner wall of the machine body 1 above the sieve plate. The inclined bucket 10 is installed on the body 1, and pipeline accessories are installed at the tangential position of the outer wall, which are the horizontal incidence pipeline 8 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com