Large-particle heavy metal ore concentrating machine

A heavy metal and mineral processing technology, applied in solid separation, chemical instruments and methods, grids, etc., can solve problems such as damage to health, easy damage to parts, and difficulty in collecting dust, and achieve environmental protection, convenient use, and mineral processing efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention is described in detail below in conjunction with the accompanying drawings and specific embodiments:

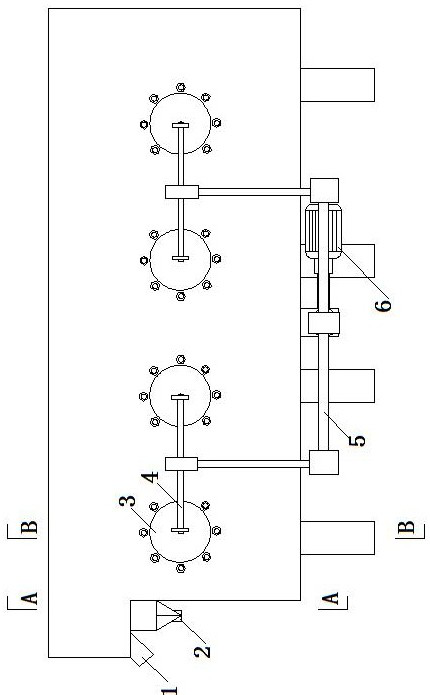

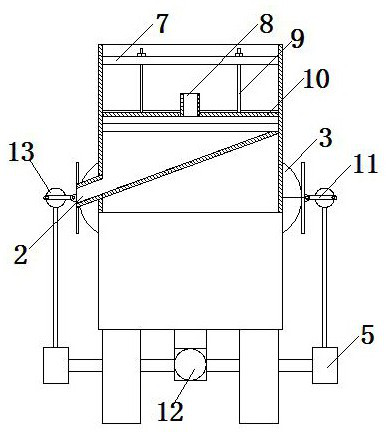

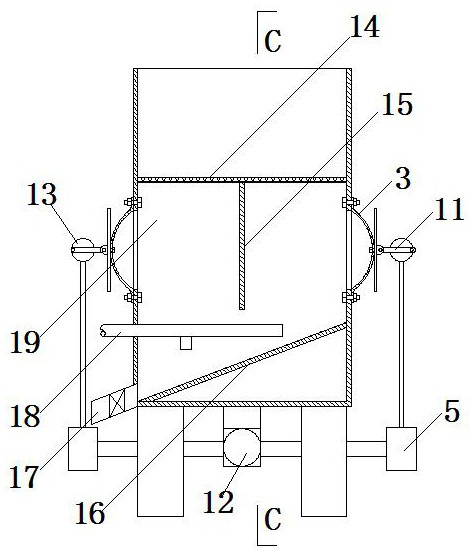

[0029] like figure 1 , figure 2 , image 3 , Figure 4 As shown, the large particle heavy metal ore dressing machine of the present invention includes a dressing table and a driving device. The ore dressing platform includes a stepped bearing platform and a water cavity formed by fixed connection of at least two ore bearing nets 14 . The preferred range of values for the ore carrying net 14 is 2-6 pieces, preferably 4 pieces. The ladder-shaped bearing platform is fixed on the upper part of the water cavity for carrying the optional ore. The end of the ladder-shaped carrying platform is provided with a discharging device. The discharging device includes a dividing plate 10 , a concentrate outlet 2 and a waste outlet 1 . The diverter plate 10 is fixed above the end of the ladder-shaped bearing platform and there is a gap between the front ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com