Machine room capable of rapid heat dissipation and heat dissipation method for same

A heat-dissipating, machine room technology, applied in heating methods, household heating, mechanical equipment, etc., can solve problems such as poor air convection conditions, safety hazards, high temperature layout and dead ends, etc., to achieve rapid heat exchange, save power consumption, Overcoming the effect of ventilation dead ends

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0034] Figure 1 to Figure 4 Some embodiments according to the invention are shown.

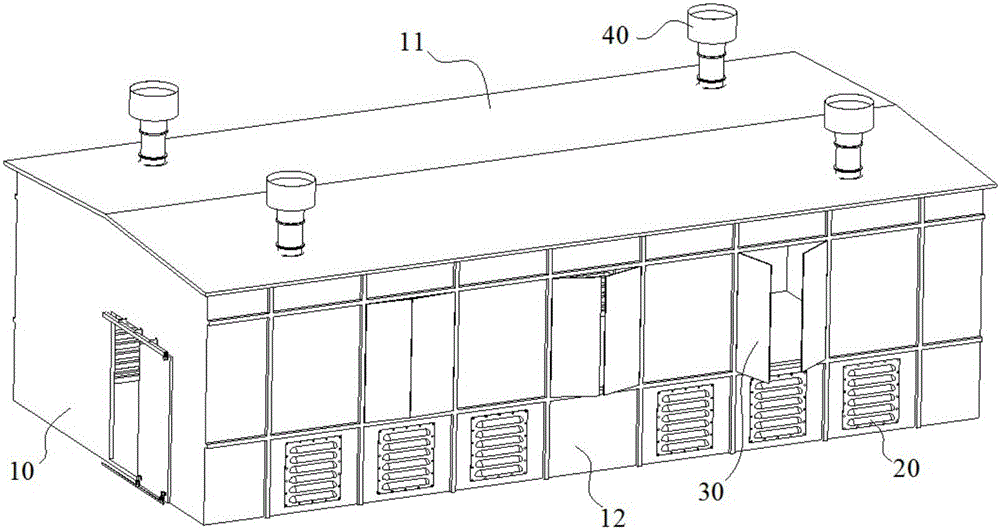

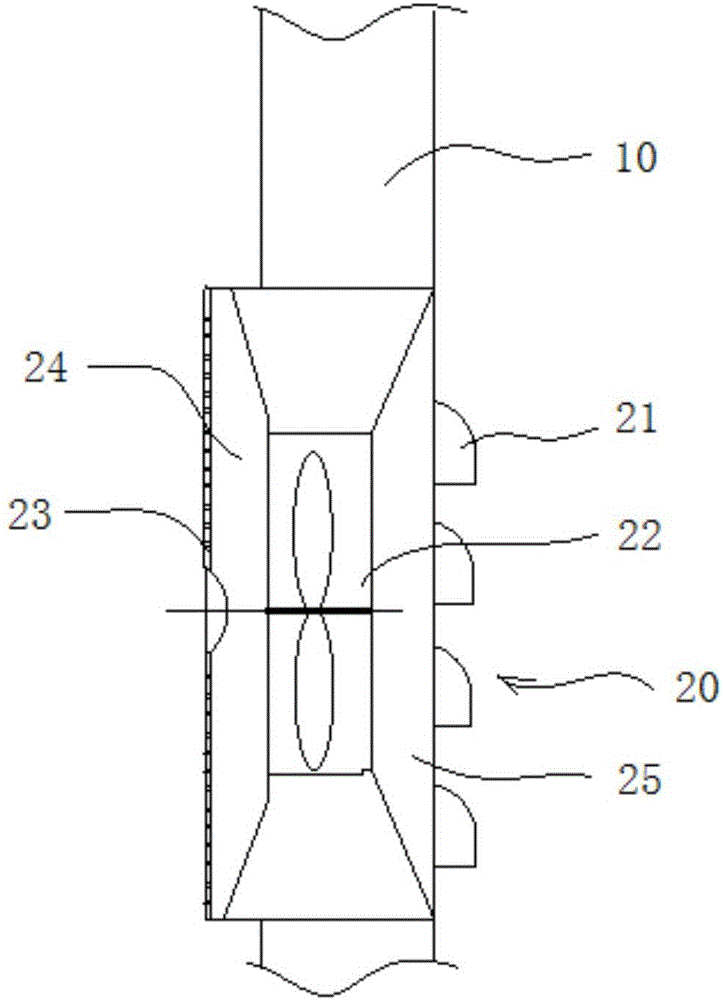

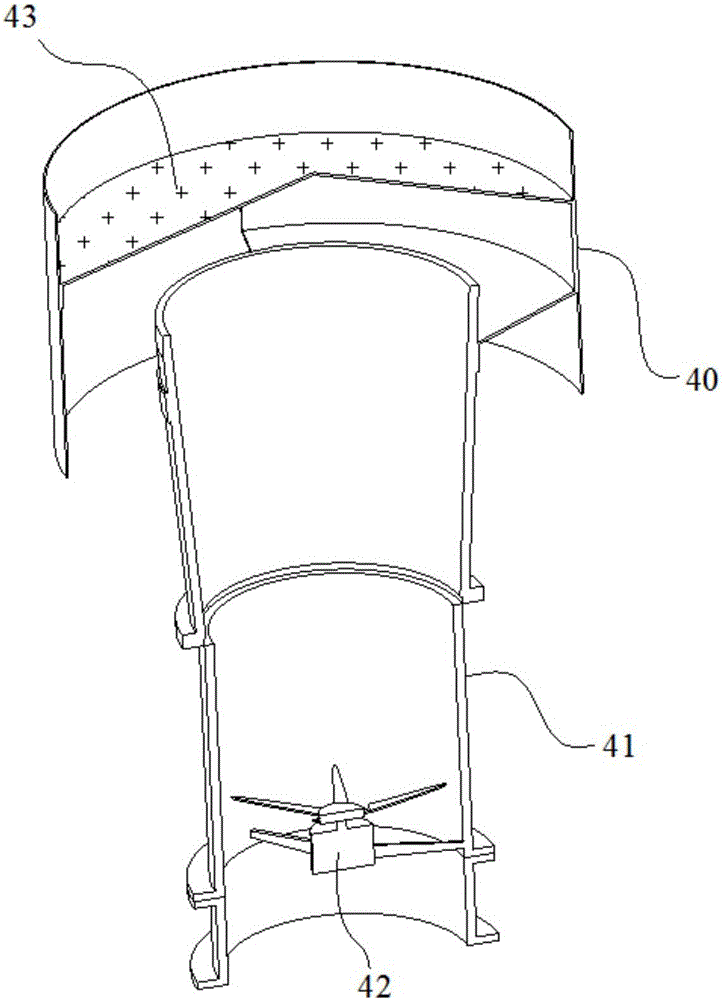

[0035] Such as Figure 1 to Figure 3 As shown, the rapid heat dissipation machine room includes a machine room main body 10, and the machine room main body 10 includes wall surfaces 12 on opposite sides and a roof 11 on the top. A plurality of first ventilation devices 20 are provided on the lower side of each wall surface 12, and the roof 11 is provided with A plurality of second ventilation devices 40 , the second ventilation devices 40 include an air duct 41 and a filter 43 arranged above the air duct 41 , and a first fan 42 is arranged in the air duct 41 .

[0036] In an embodiment, the above-mentioned ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com