Piston ring fatigue testing machine and fatigue testing method

A technology of fatigue testing machine and piston ring, which is applied in the testing of mechanical components, testing of machine/structural components, measuring devices, etc. It can solve the problems of unstable speed, easy falling off of piston rings, and complicated mechanism, so as to improve the degree of automation , Improve work efficiency, improve the effect of test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

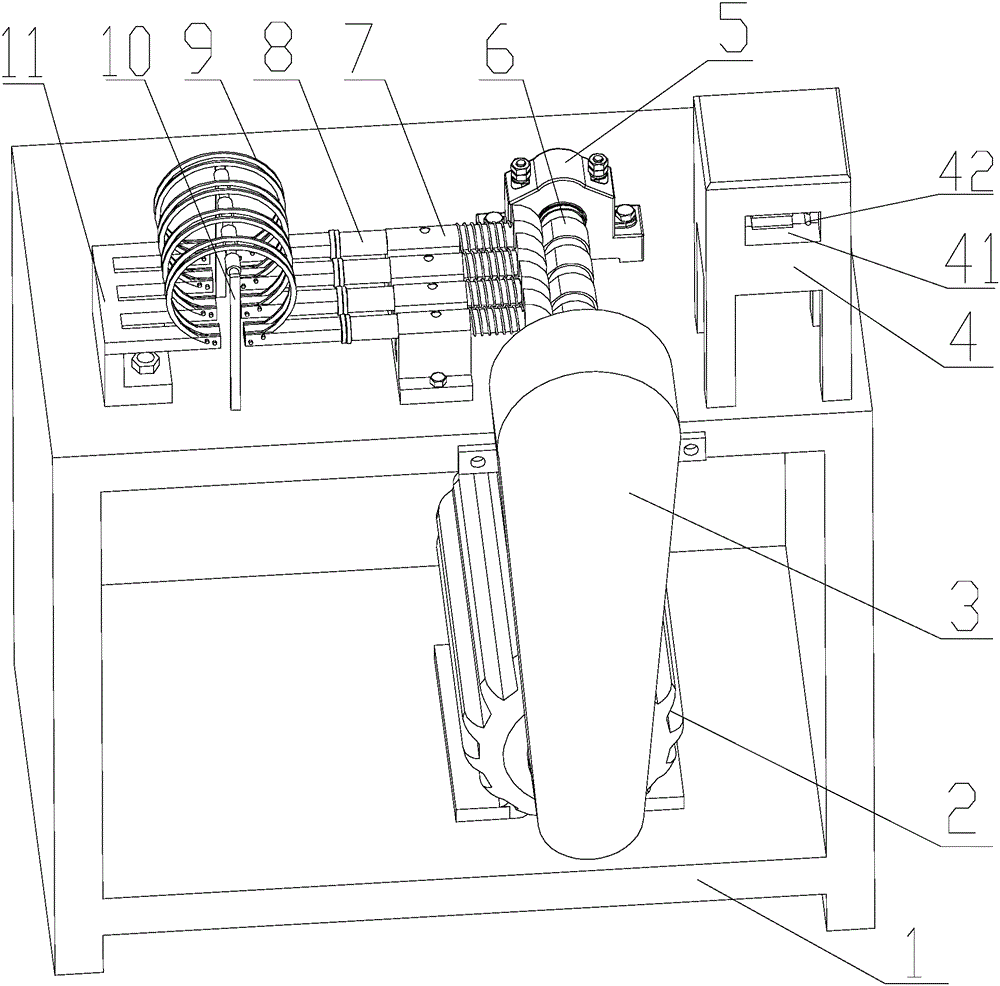

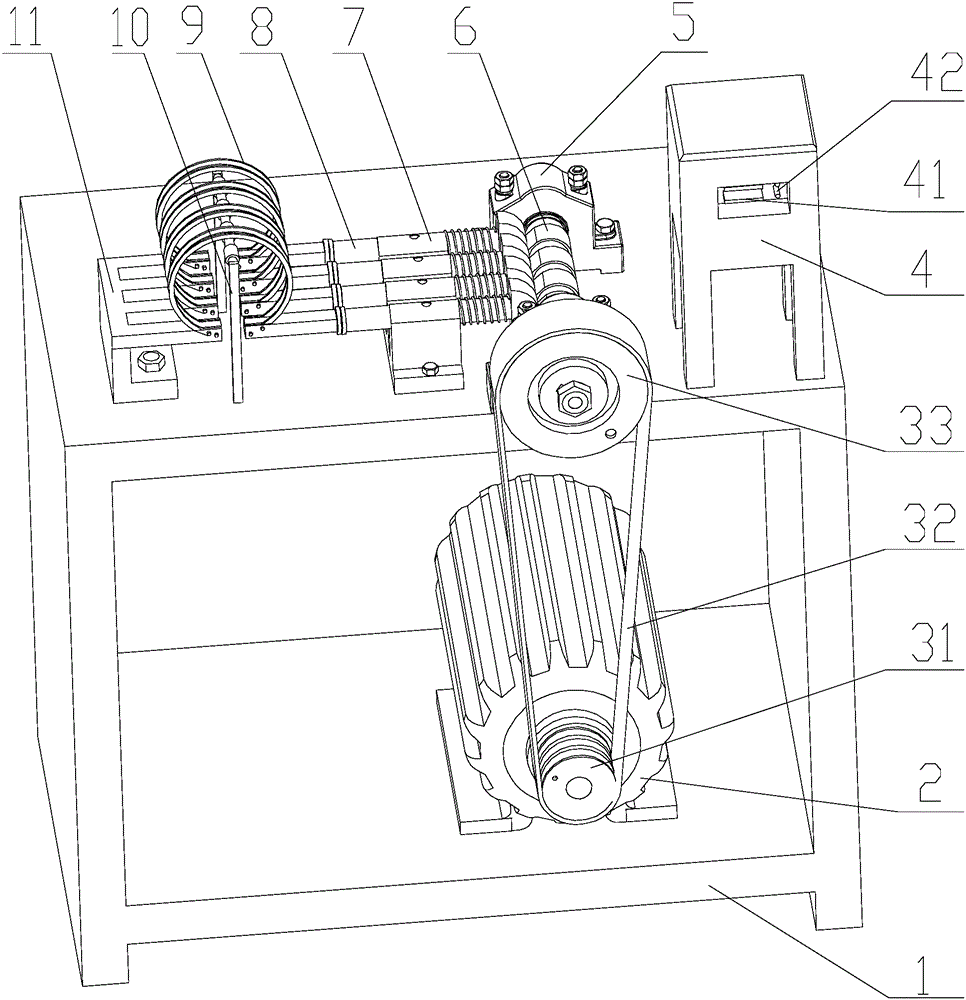

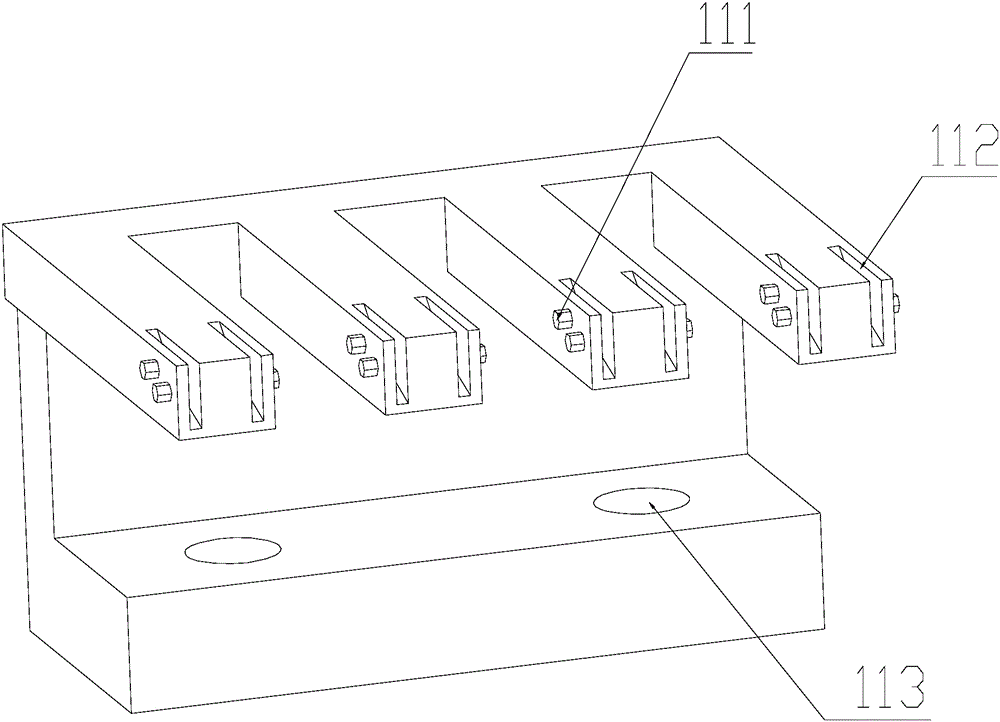

[0037] Such as Figure 1-6 Shown, a kind of piston ring fatigue testing machine, it comprises base 1, and the lower end of described base 1 is fixedly installed with three-phase asynchronous motor 2, and described motor 2 is connected with camshaft 6 through belt pulley 3, and on described camshaft 6 The cam and one end of the spring push rod 8 form a cam push rod transmission fit, the middle part of the spring push rod 8 forms a sliding fit with the guide rail 7, and the other end of the spring push rod 8 is connected to the piston ring clamp body 11, and the piston A transmission sensor 10 is arranged in the middle of the ring clamp body 11 , and the sensor 10 is electrically connected to the control cabinet 4 , a counter is arranged in the control cabinet 4 , and the control cabinet 4 is installed on the top of the base 1 . The fatigue life of the piston ring can be studied through the above fatigue testing machine, and the structure of the equipment is simplified through t...

Embodiment 2

[0047] A method of performing a fatigue test using any ring fatigue testing machine, which includes the following steps:

[0048] S1: fix the two ends of the openings of the eight piston rings 9 to be tested on the fixed part and the two ends of the movable part of the piston ring clamp body 11 respectively, and fix them with screws;

[0049] S2: According to the model of the piston ring 9 to be detected and the use environment, set the motion law of the camshaft 6, set it to a quintic polynomial motion law, and ensure that the stroke h of the push rod is the free opening size of the piston ring , set the number of fatigue tests through the button on the control cabinet 4;

[0050] S3: By starting the motor 2, the driving wheel 31 is driven by the motor 2, the driving wheel 31 drives the driven wheel 33 to rotate through the belt 32, the driven wheel 33 is connected with the camshaft 6 through a flat key, and the power is transmitted to the spring push rod 8, and the spring pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com