Drawer type UPS power board fan heat dissipation system

A cooling system and drawer-type technology, applied in the field of drawer-type UPS power board fan cooling system, can solve problems such as poor cooling, and achieve the effect of maintaining temperature and avoiding local high temperature problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

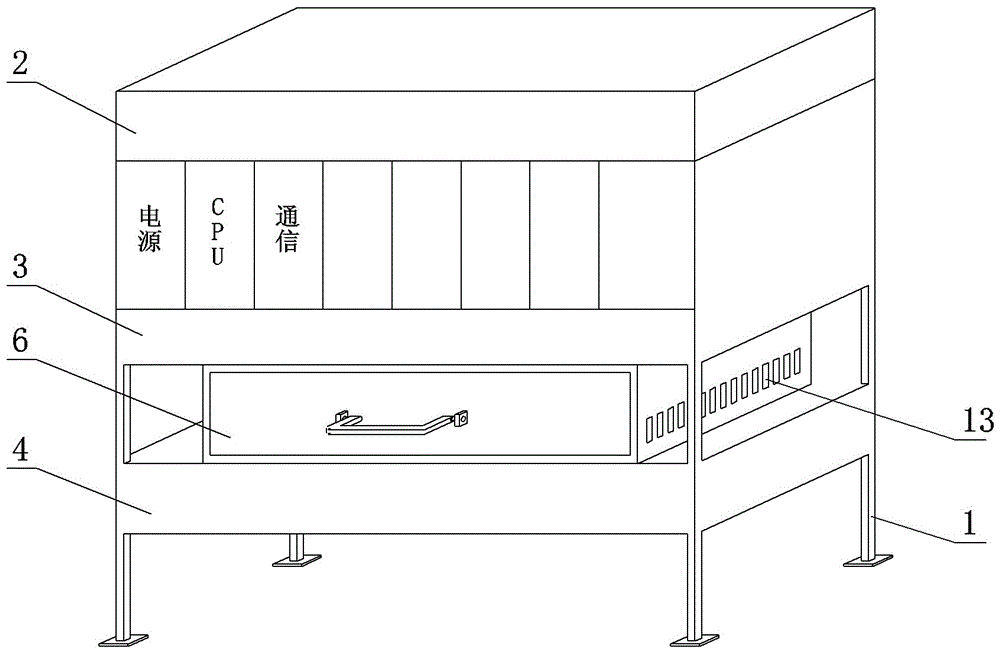

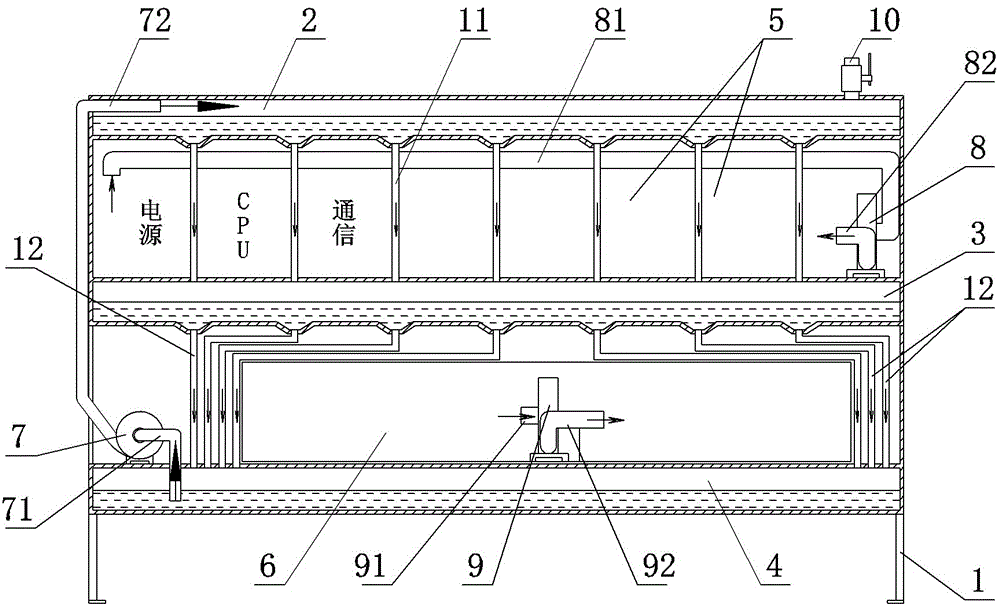

[0018] Embodiment 1: as figure 1 In the drawer-type UPS power board fan cooling system, an upper water tank 2 , a middle water tank 3 and a lower water tank 4 are sequentially arranged on the bracket 1 from top to bottom.

[0019] Between the upper water tank 2 and the lower water tank 4 there are multiple rows of parallel upper layer heat exchange tubes 11 vertically distributed, between the middle water tank 3 and the lower water tank 4 vertically distributed multiple rows of parallel lower layer heat exchange tubes 12 .

[0020] A closed industrial computer installation room 5 is provided between the upper water tank 2 and the lower water tank 4 , and the upper layer heat exchange tubes 11 are distributed in the industrial computer installation room 5 .

[0021] An internal fan 8 is installed in the installation room 5 of the industrial computer to fully circulate the air in the closed room to form an internal air circulation. The air inlet pipe of the internal circulation...

Embodiment 2

[0028] Embodiment 2: On the basis of Embodiment 1, the industrial computer installation room 5 is divided into a plurality of independent chambers, and a plurality of air inlet pipes of the internal circulation fan are respectively located at the top of each independent chamber, and a plurality of air outlet pipes are respectively located in each independent chamber. Separate room bottom.

Embodiment 3

[0029] Embodiment 3: On the basis of Embodiment 1, cooling fins are provided on the outside of the upper heat exchange tube or the lower heat exchange tube.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com