Extension-type winder applicable to electric wires and processing technique of extension-type winder

A wire and cable and processing technology, applied in the field of retractable wire winder and its processing technology, can solve the problems of waste of wire winder, messy desktop, heat collection of wires, etc. The effect of improving the tightness of the connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

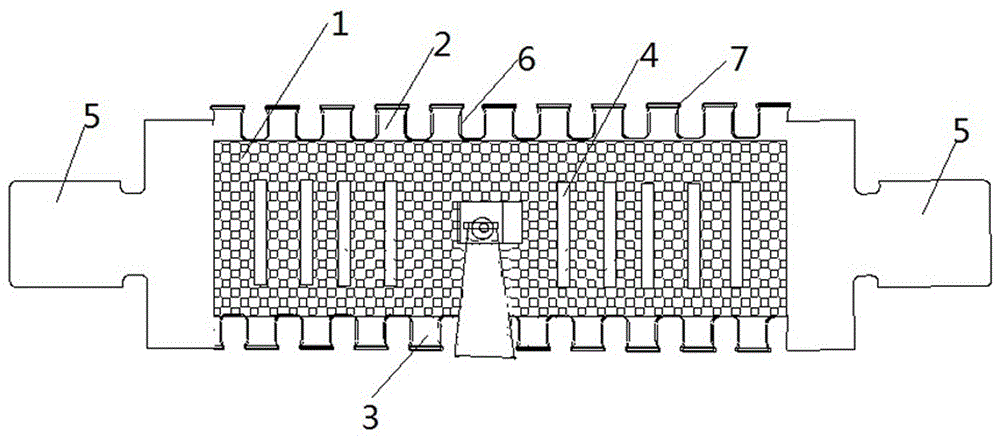

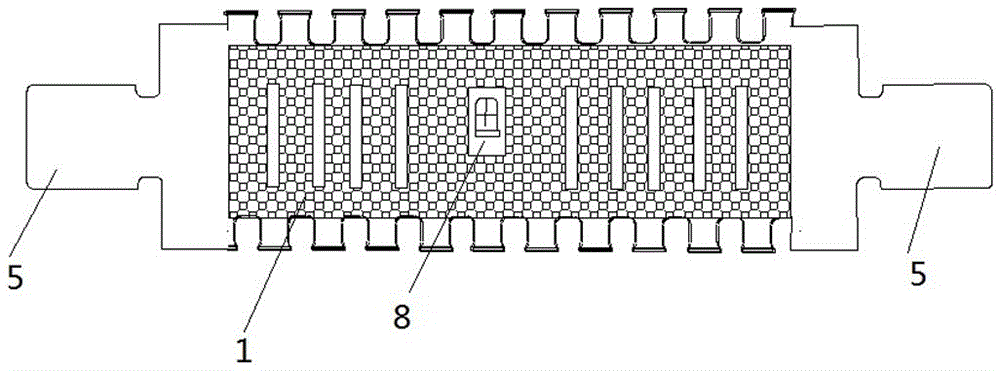

[0035] Such as figure 1 with figure 2 A retractable wire winder for electric wires and cables is shown, comprising: a wire winder body 1, the upper and lower sides of the wire winder body 1 are respectively provided with a first rack 2 and a second rack 3 , the middle part is provided with a perforation 4, and its two ends are provided with clamping strips 5, the surface of the said winder body 1 is concave-convex, and the first rack 2 and the second rack 3 are Lugs 7 are provided on both sides of the teeth, protective sleeves 6 are provided on the first rack 2 and the second rack 3 , and the clamping strip 5 is matched with the through hole 4 .

[0036] The clamping bar 5 described in this embodiment is in a convex shape, and inner grooves are provided on both sides of one end close to the end of the winding body 1 .

[0037] The inside of the protective cover 6 described in this embodiment is concave-convex, and its inner edge is provided with lugs, which cooperate with t...

Embodiment 2

[0042] The structure of the wire winder used in the processing technology of the retractable wire winder in the wire and cable described in this embodiment is the same as that in Embodiment 1.

[0043] Such as figure 1 with figure 2 A retractable wire winder for wires and cables is shown, comprising: a wire winder body 1, the upper and lower sides of the wire winder body 1 are respectively provided with a first rack 2 and a second rack 3 , the middle part is provided with a perforation 4, and its two ends are provided with clip bars 5, the surface of the said winding device body 1 is concave-convex, and the first rack 2 and the second rack 3 are Lugs 7 are provided on both sides of the teeth, protective sleeves 6 are provided on the first rack 2 and the second rack 3 , and the clamping strip 5 is matched with the through hole 4 .

[0044] The clamping bar 5 described in this embodiment is in a convex shape, and inner grooves are provided on both sides of one end close to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com