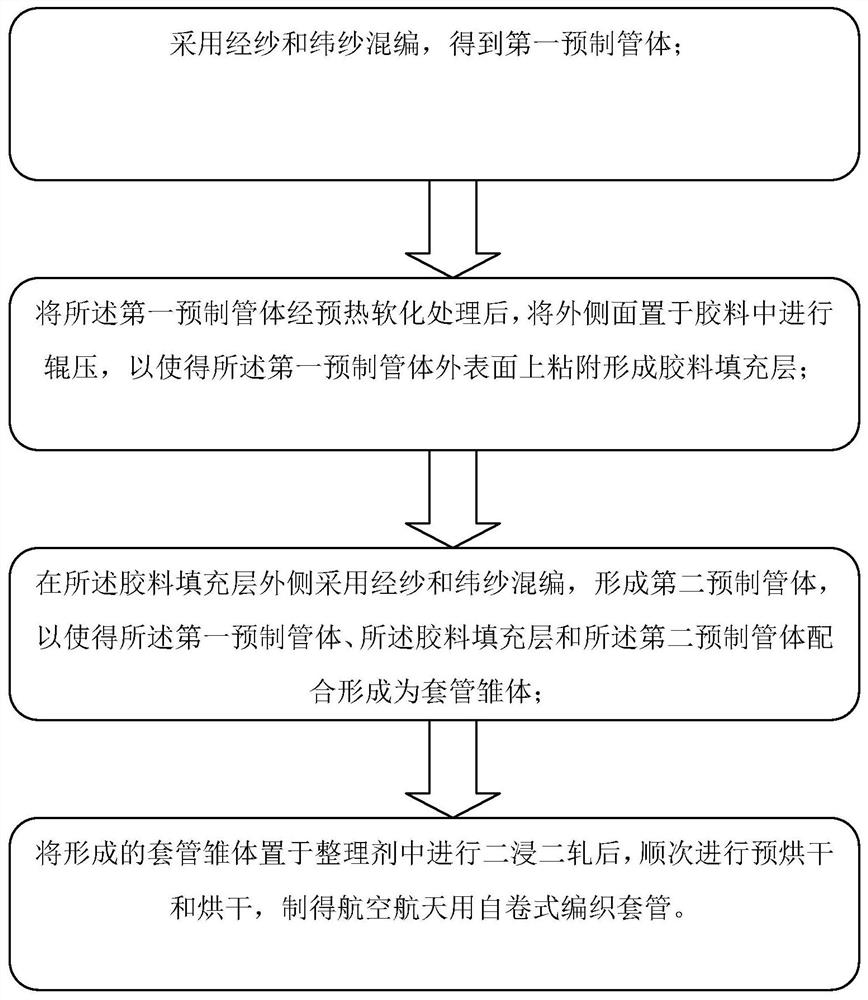

Self-rolling braided sleeve for aerospace and preparation method thereof

An aerospace and self-rolling technology, applied in chemical instruments and methods, textiles, fabrics, etc., to achieve the effects of improving salt spray resistance, improving connection tightness, improving toughness and breaking strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Specific embodiments of the present invention will be described in detail below. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

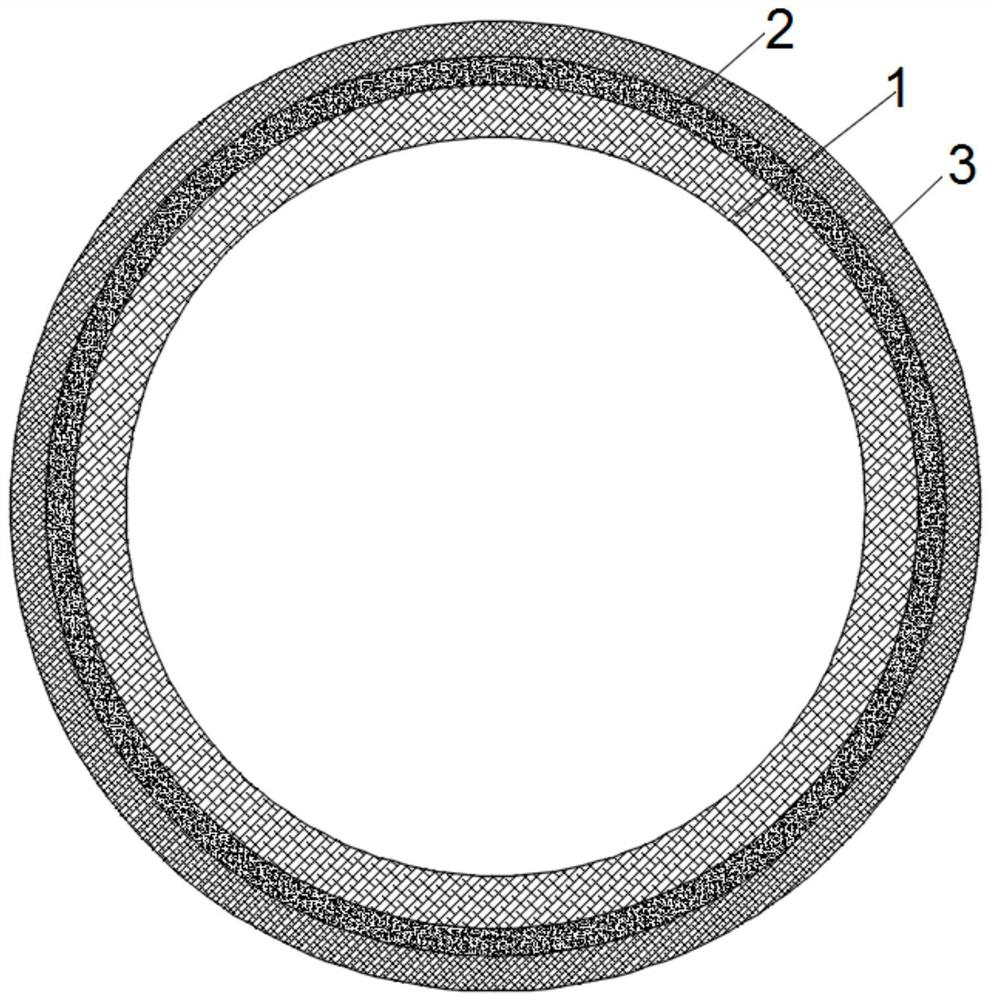

[0043] Such as figure 2 As shown, the present invention provides a self-rolling braided casing for aerospace, which includes a first tube body 1 and a rubber filling layer 2 formed sequentially from the inside to the outside. and the second body 3; and,

[0044] The first pipe body 1 and the second pipe body 3 each include a warp yarn and a weft yarn, the warp yarn is a single fiber material, and the weft yarn is a multi-fiber material;

[0045] The rubber filling layer 2 includes colloid base material and carbon fiber.

[0046] The above design adopts the method of fitting the first pipe body 1 and the second pipe body 3, and further fills the rubber filling layer 2 formed by mixing colloid and carbon ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com