Environment-friendly composite fabric manufacturing system

A processing device, an environmentally friendly technology, applied in the direction of lamination devices, layered products, lamination auxiliary operations, etc., can solve the problems of unfavorable cost saving, the effect of wrinkle removal cannot be guaranteed, etc., to achieve quality assurance and improve connection. The effect of compactness, lowering manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The content of the present invention will be described below in conjunction with specific embodiments.

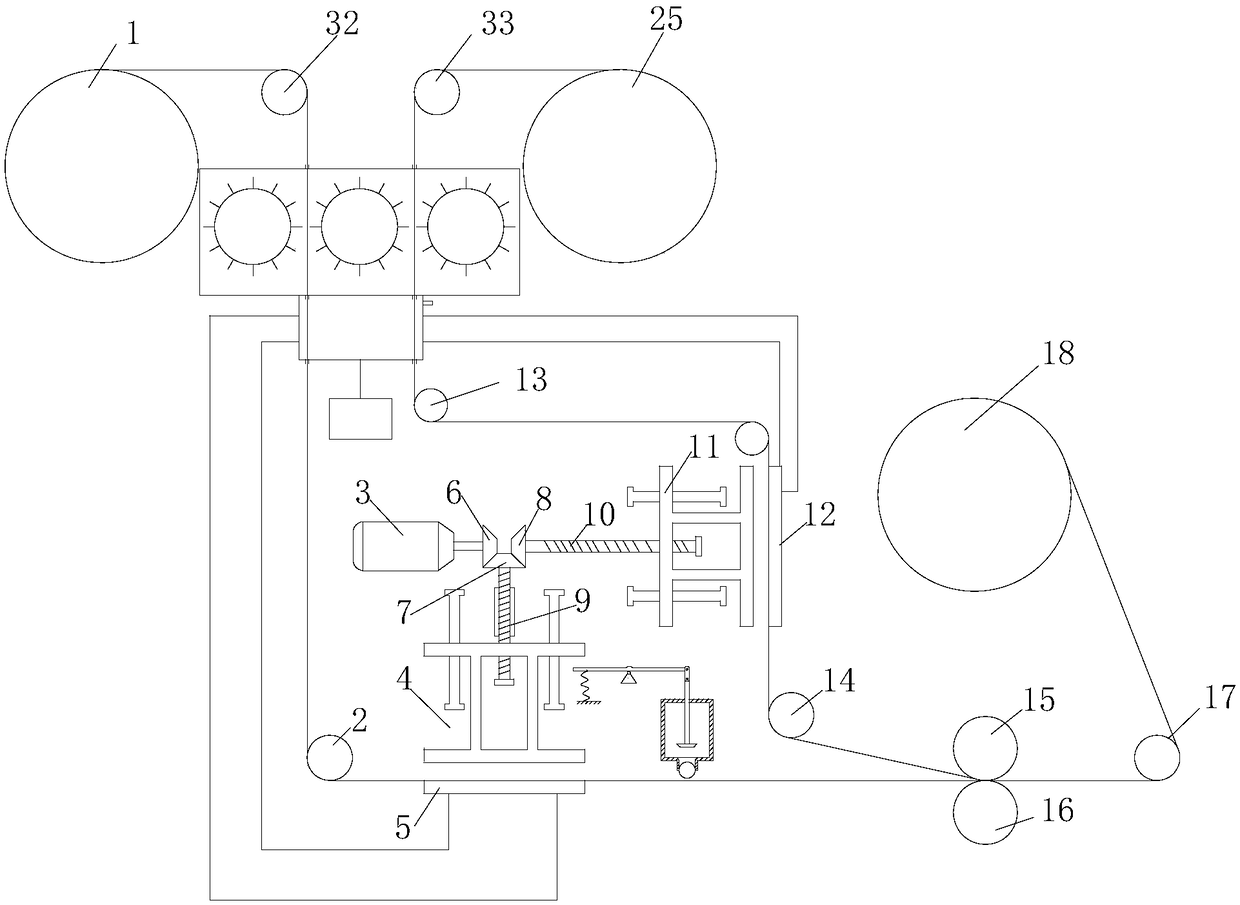

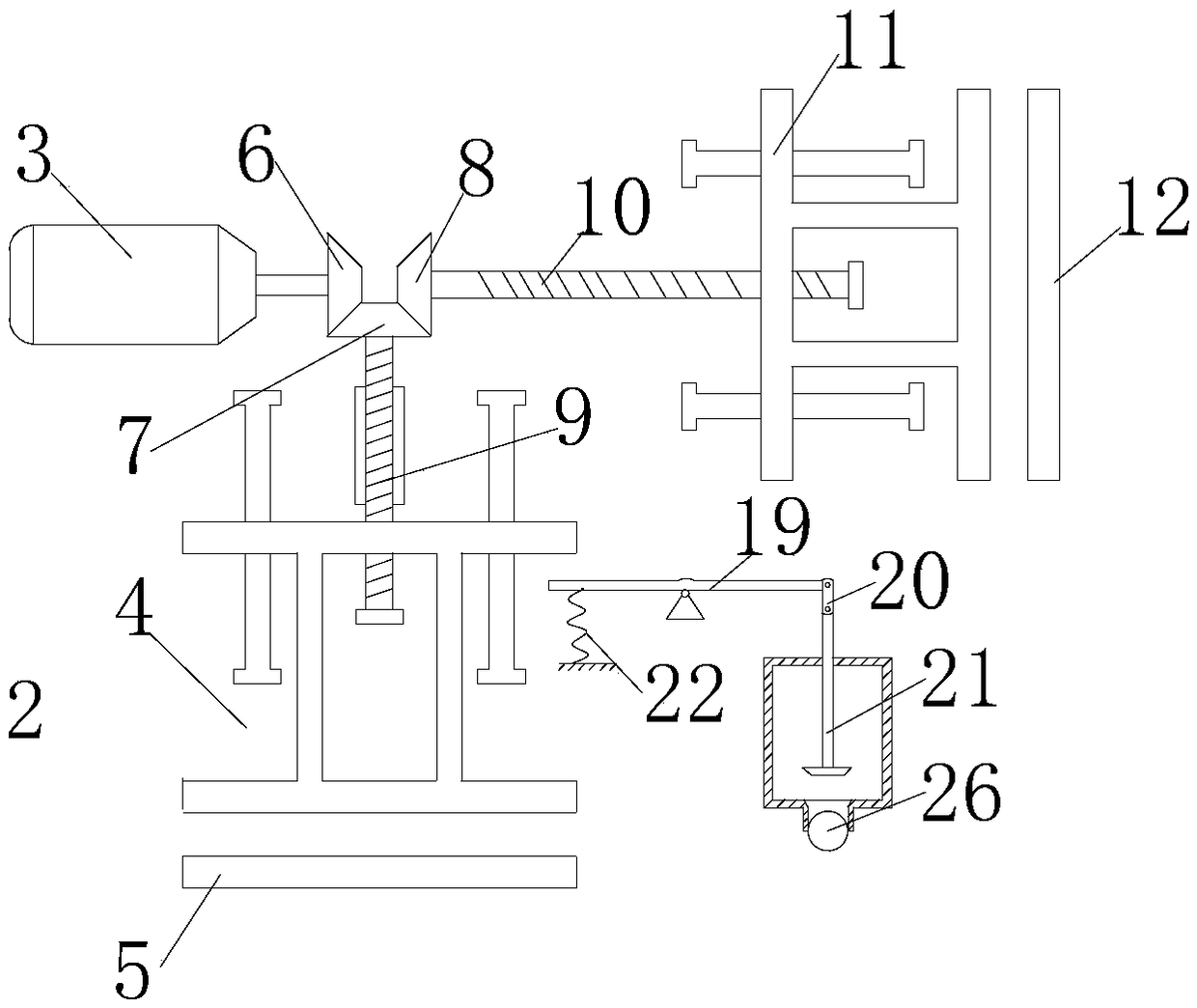

[0036] refer to Figure 1~3 , an environment-friendly composite cloth production and processing device proposed by the present invention. The device includes: a base cloth roll 1 wound with a base cloth, a fabric roll 25 wound with a fabric, a dust removal unit, a first leveling unit, and a gluing unit , the second leveling unit, the pressing roller unit and the receiving roller 18.

[0037] The base cloth is output by the base cloth roller 1, and the fabric is output by the fabric roll 25. The dust removal unit is used to remove dust from the base cloth and the fabric. After the dust removal treatment, the base cloth can enter the first leveling unit horizontally Inside, the fabric can enter into the second flattening unit vertically.

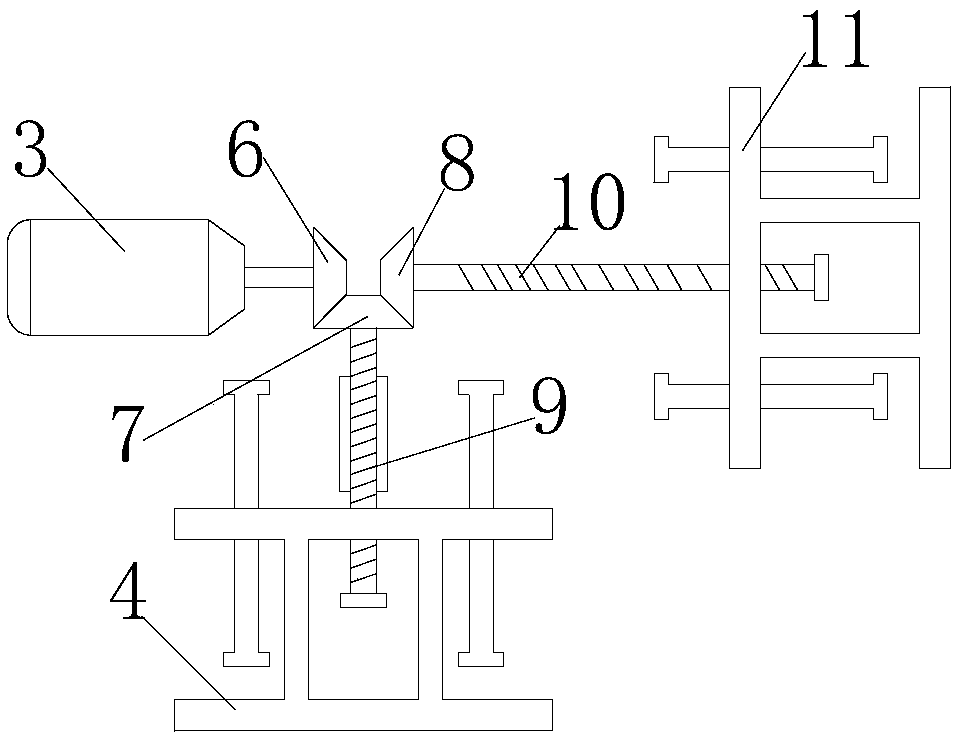

[0038] The first leveling unit includes a first base 5 and a first leveling mechanism, the first leveling mechanism is located ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com