Secondary seed suction assisting self-disturbance seed discharge plate

A kind of seeding tray and tray body technology, applied in sowing, planter parts, applications, etc., can solve the problems of missed sowing, seed hole filling, short filling time, etc., to reduce inter-species resistance and improve seed filling performance , avoid the effect of missing seeding and holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

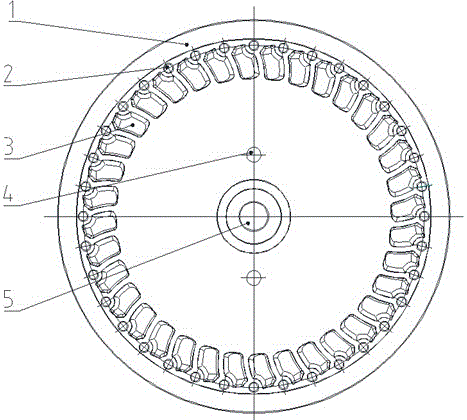

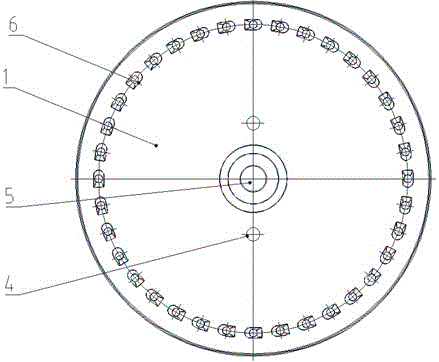

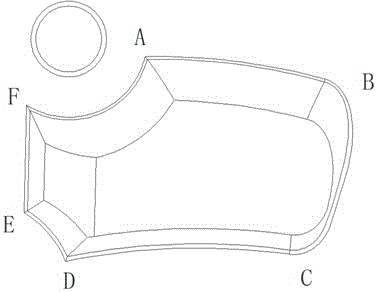

[0023] refer to figure 1 , figure 2 and Figure 4 , a secondary auxiliary seed-suction self-disturbance seed-discharging disc, comprising a disc body 1, on which a mounting hole 5, a positioning hole 4, a seed-filling hole 2, a seed-stirring groove 3 and a seed-clearing groove 6 are arranged; The center of the disc body 1 is provided with a mounting hole 5, and the periphery of the mounting hole 5 is provided with a positioning hole 4; a plurality of seed-filling holes 2 are evenly distributed around the disc body 1, and the inside of each seed-filling hole 2 is correspondingly provided with a seed stirring groove 3 ; The back of the disc body 1 is provided with a seed clearing tank 6, which corresponds to the position of the seed filling hole 2.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com