Air-suction type spiral grooved wheel seed sowing device

A kind of spiral groove, air suction technology, applied in the direction of planter parts, etc., can solve the disturbance, and at the same time, the problems of collision, bounce and friction, affecting the growth of crops, and the phenomenon of seed pulsation can be solved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing:

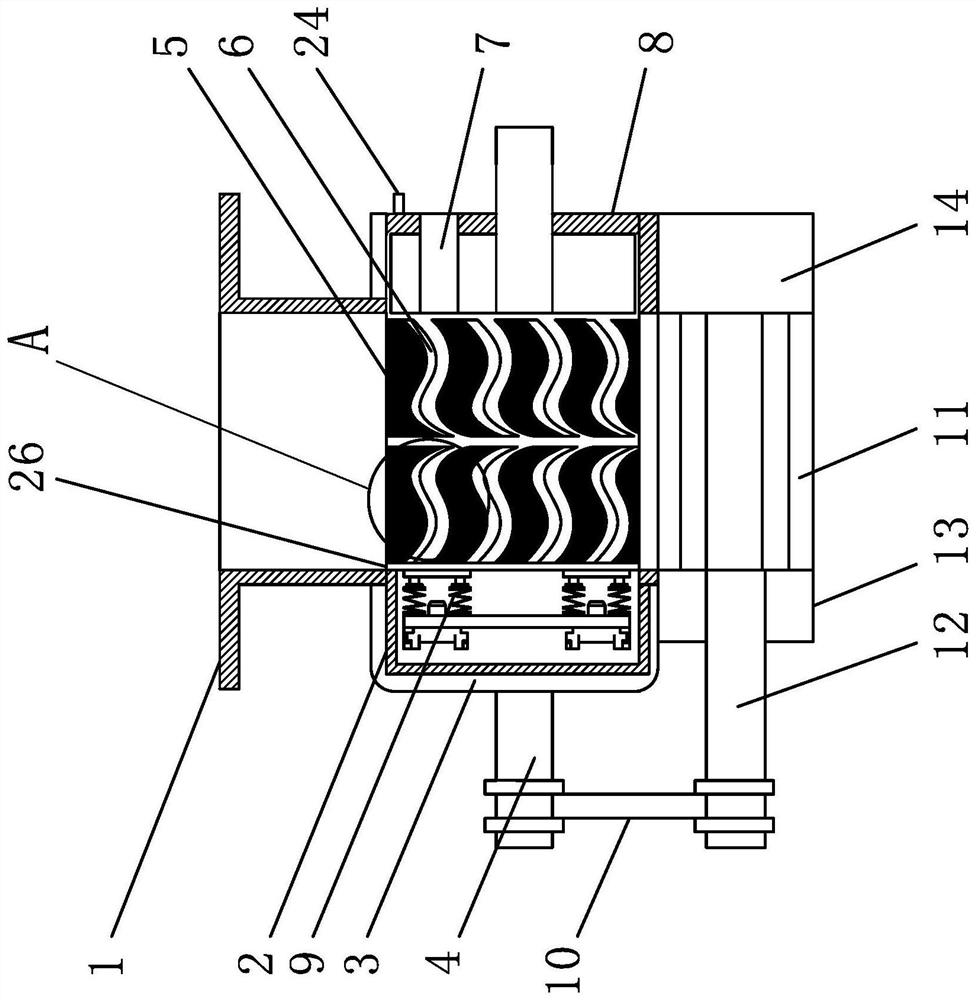

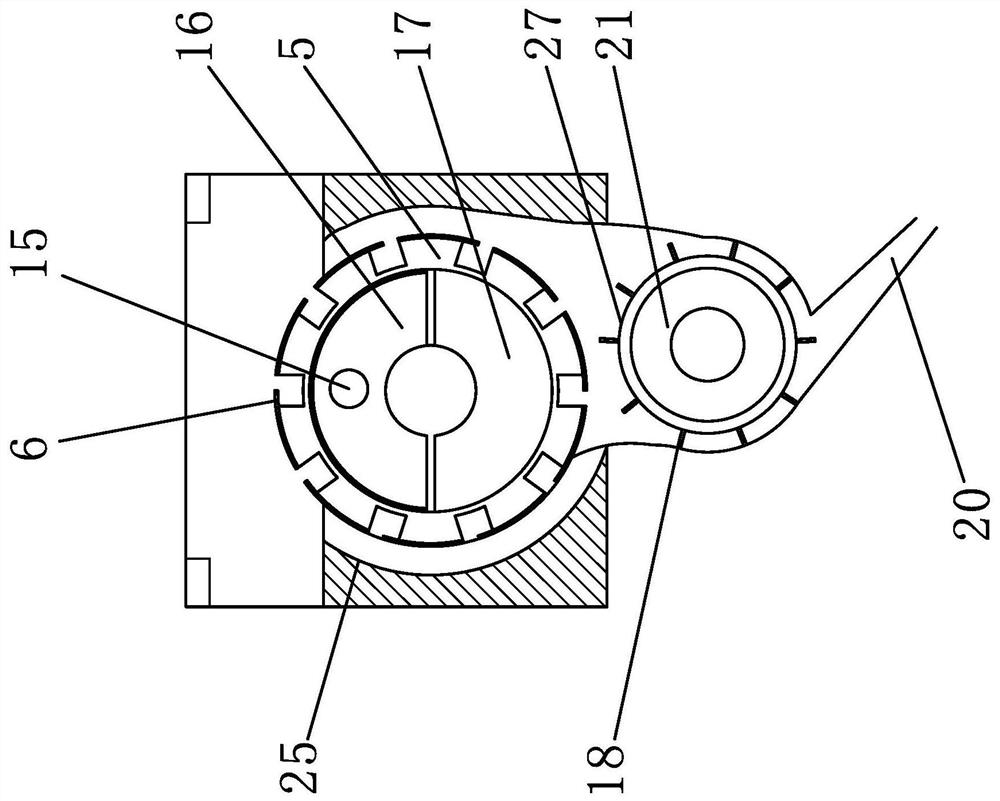

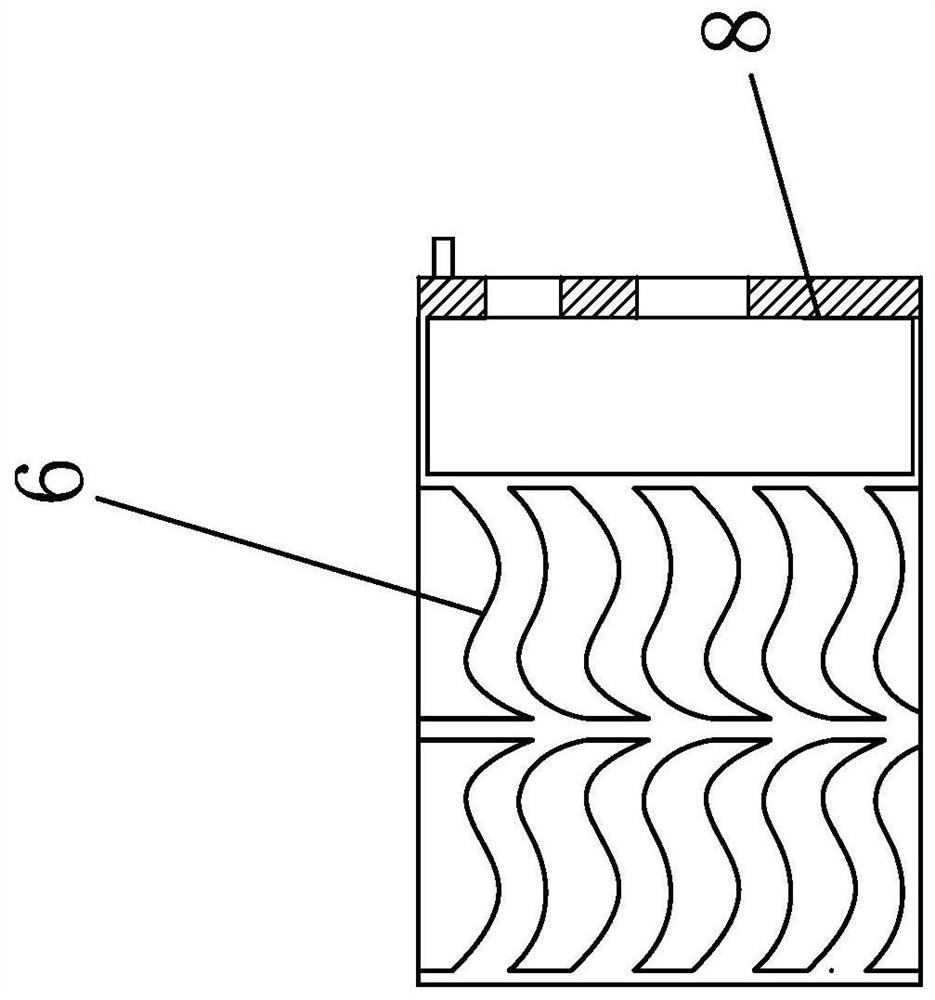

[0015] Such as Figure 1-4 As shown, an air-suction spiral groove wheel seed metering device is composed of a housing 1, a blocking sleeve 2, a blocking sleeve end cover 3, a seeding shaft 4, a seeding wheel 5, an adjusting sleeve 6, an air suction Pipeline 7, seed wheel end cover 8, electromagnetic vibrator 9, adjustment handle 24, seed protection plate 25, air suction chamber 16, zero pressure zone 17, seed guiding device 24, baffle plate 26; seed wheel 5 is arranged on Inside the housing 1, the seeding shaft 4 is arranged in the shaft hole of the seeding wheel 5, and the external motor drives the seeding wheel 5 to rotate, and the right end face of the blocking sleeve 2 is fixedly connected with the left end face of the baffle plate 26, and the baffle plate 26 The right end face of the seeding wheel 5 fits with the left end face of the seeding wheel 5, the adjusting sle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com