Air-suction type adjustable-pitch helical bevel gear seed sowing device

A spiral cone and air-suction technology, applied in the direction of sowing, planter parts, interval quantitative sowing machinery, etc., can solve problems such as uneven plant spacing, seed pulsation phenomenon, and affect the uniformity of seeding, and achieve uniform plant spacing And accurate, improve the filling performance, reduce the effect of seeding pulsation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing:

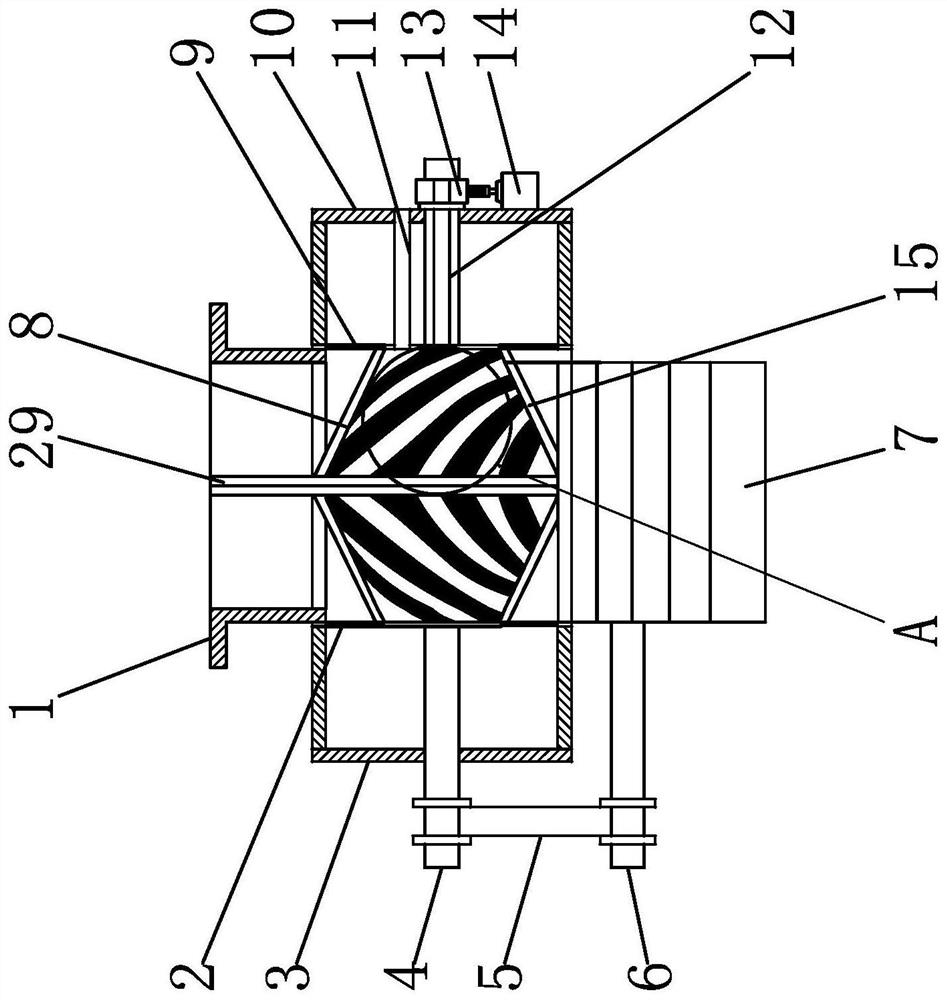

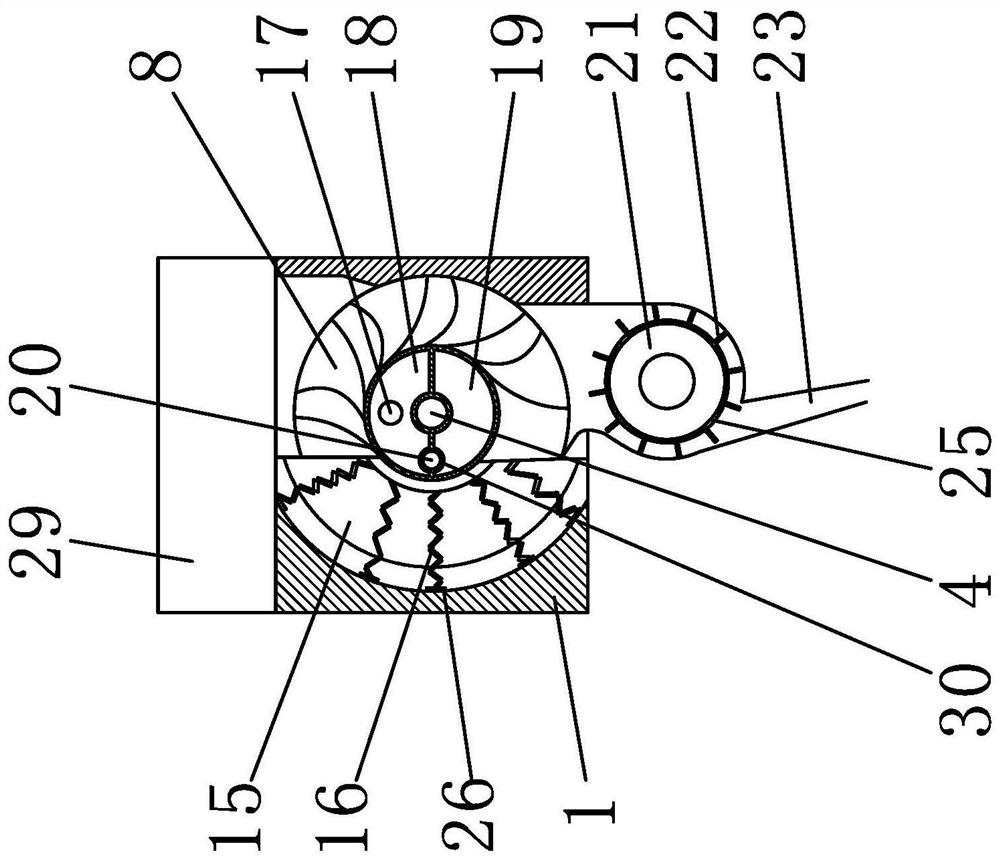

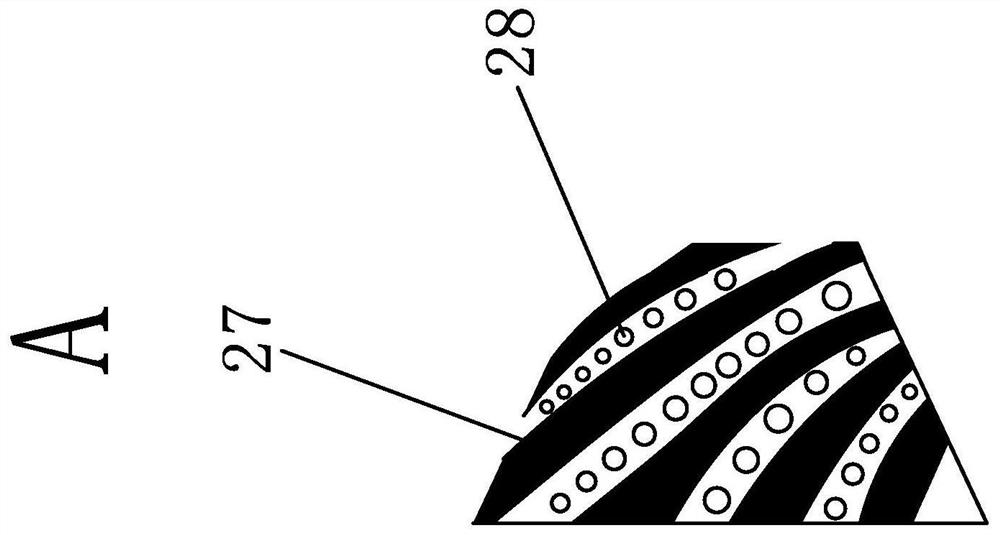

[0017] like Figure 1-4 As shown, an air-suction adjustable distance spiral bevel tooth metering device is composed of a housing 1, a left retaining ring 2, a left end cover 3, a seeding shaft 4, a belt 5, a seed guiding device 7, and a seeding device. Wheel 8, right retaining ring 9, right end cover 10, suction pipe 11, leading screw 12, leading screw transmission part 13, motor 14, seed protection plate 15, spring 16, seeding wheel partition 29 are connected to form; seeding wheel 8 is set inside the casing 1, the seeding shaft 4 is connected in the shaft hole of the seeding wheel 8, the left end cover 3 is connected to the left end surface of the casing 1, and the right end cover is connected to the right end surface of the casing 1 10. The left retaining ring 2 is arranged between the left end cover 3 and the seeding wheel 8, the right retaining ring 9 is arranged betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com