Corn in-line duckbill forced discharge device

An in-line, duckbill technology, applied in the direction of planter parts, etc., can solve the problems that restrict the rapid development of full-film double-furrow sowing technology, cannot meet the needs of corn sowing, and the duckbill is not opened in time, so as to reduce the labor of farmers. The effect of strength, improving the qualified rate of plant spacing and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

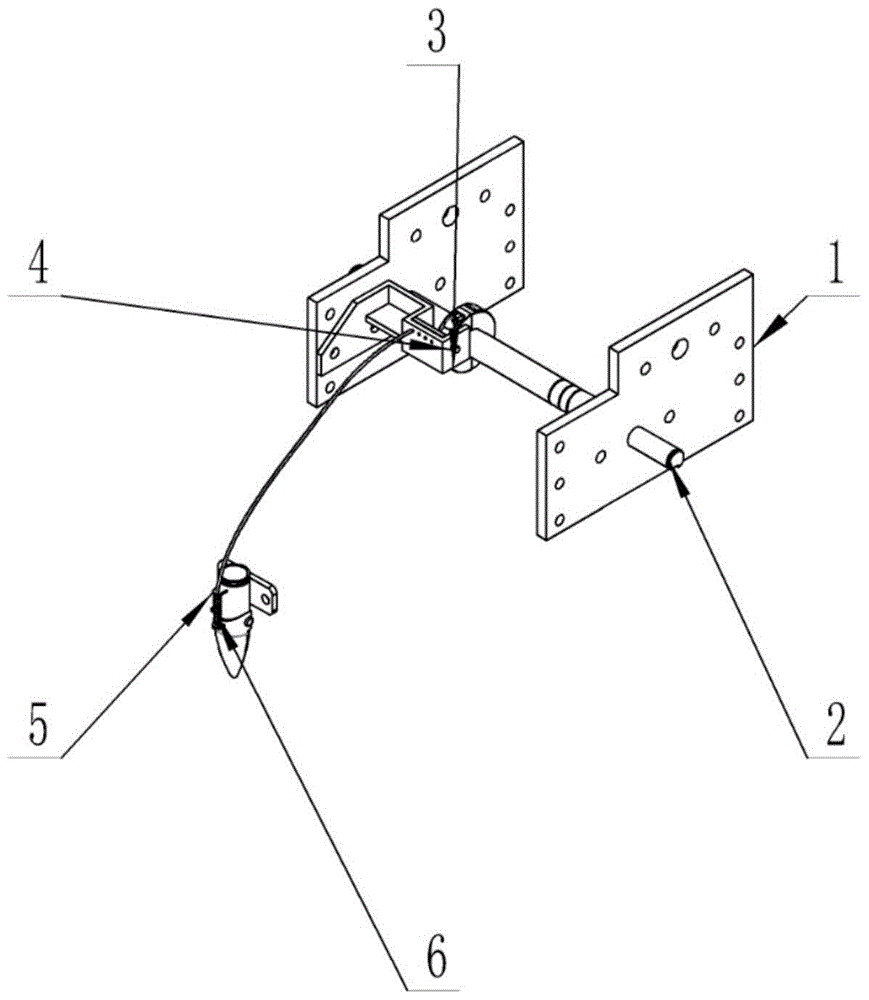

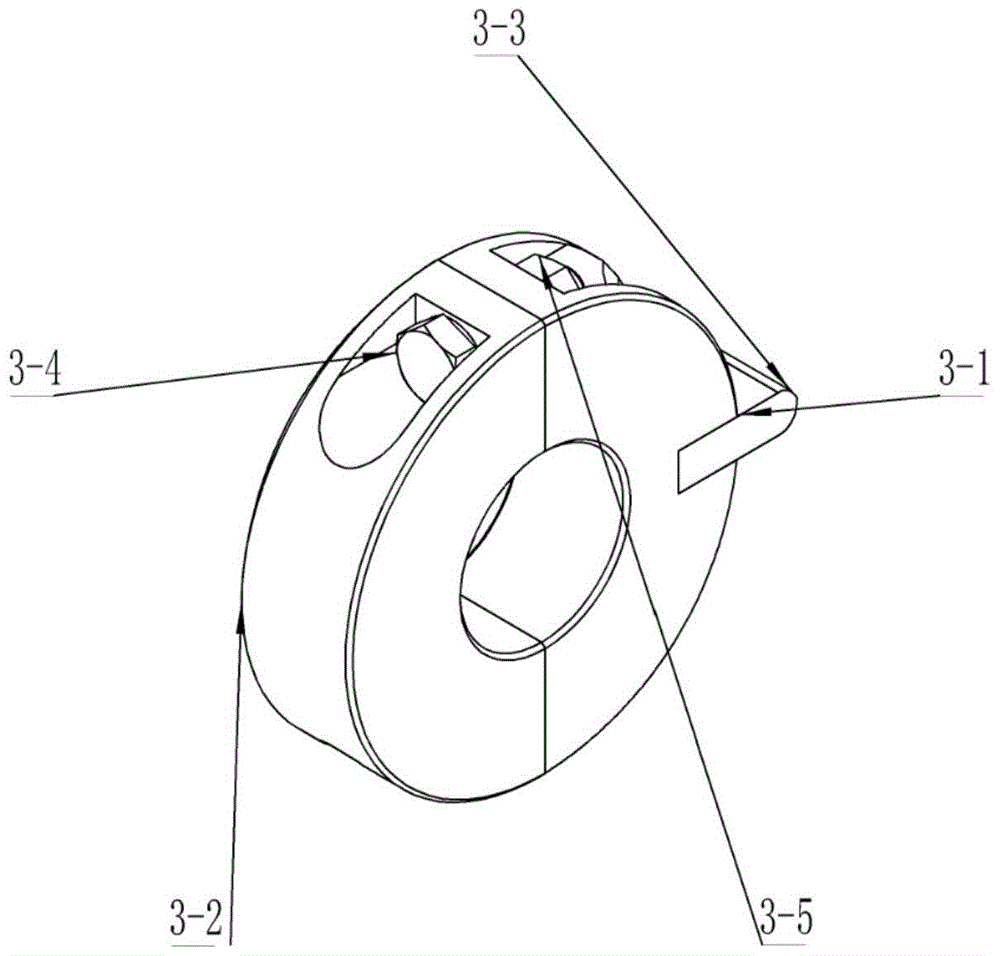

[0019] Such as Figures 1 to 5 As shown, the described corn in-line duckbill forced discharge device is characterized in that it includes an installation top plate 1 fixedly connected with the planter frame, and a camshaft 2 is installed on the installation top plate 1, and the camshaft 2 is provided with There is a cam assembly 3, and a pull-tab assembly 4 is installed corresponding to the cam assembly 3 on the board surface where the top plate 1 is installed, and the pull-tab assembly 4 is connected with the duckbill assembly 5 through a pull wire 6 .

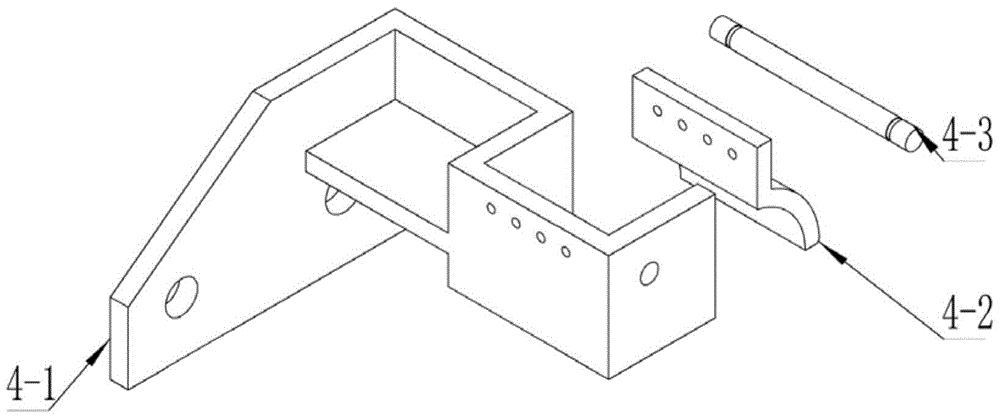

[0020] Further, the pull-tab assembly 4 includes a pull-tab frame 4-1, a pull-tab 4-2 is hinged on the pull-tab frame 4-1 through a pull-tab rotating shaft 4-3, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com