Patents

Literature

40results about How to "Avoid being unable to discharge" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

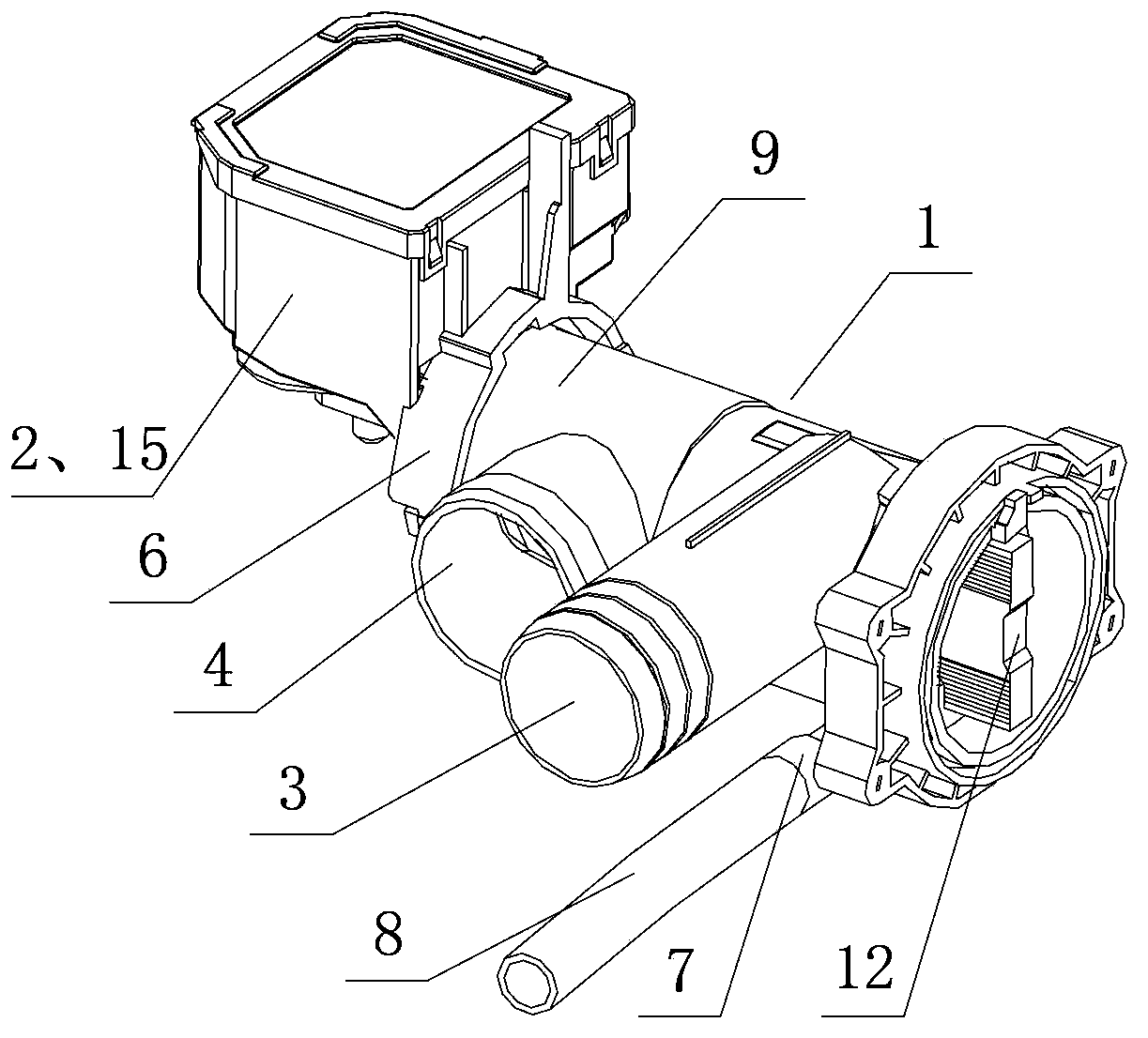

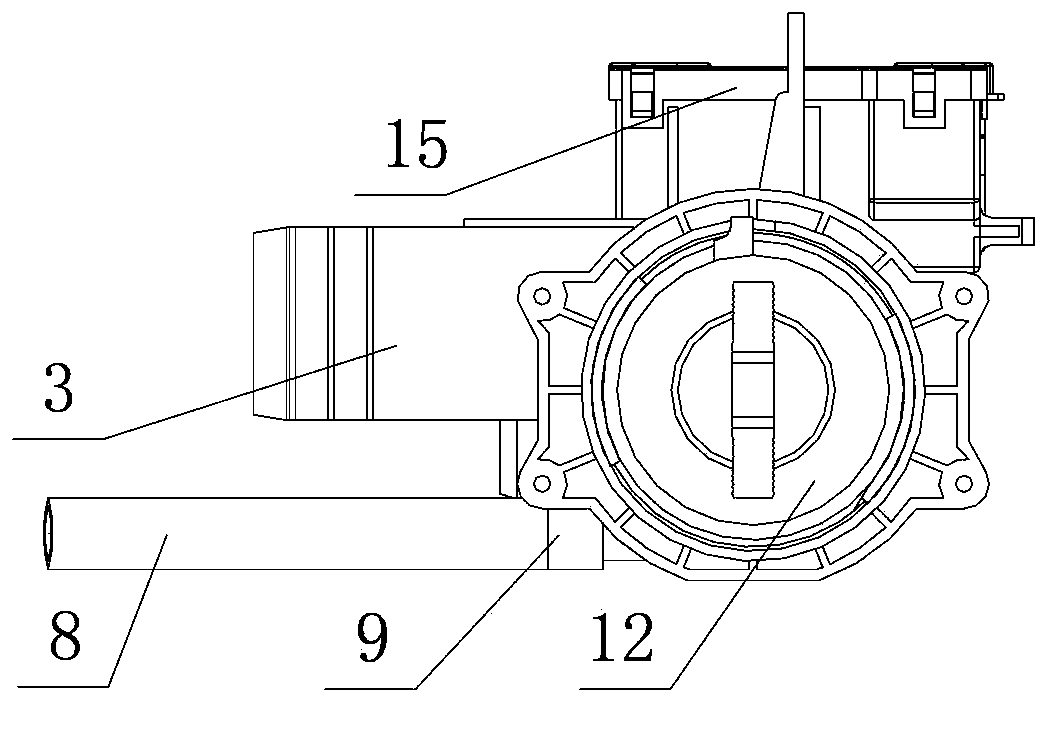

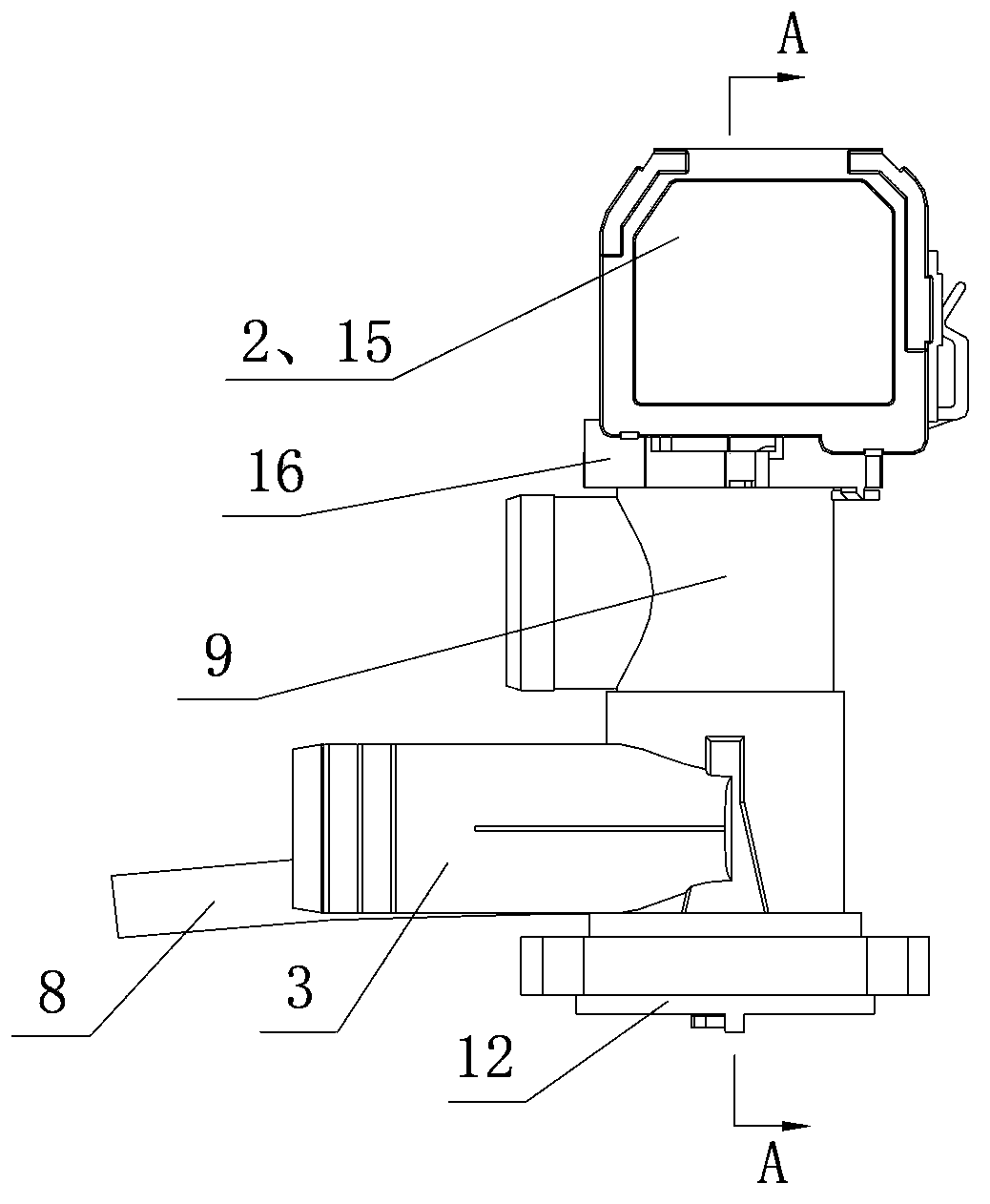

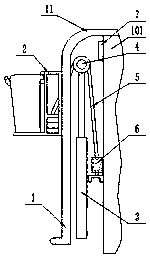

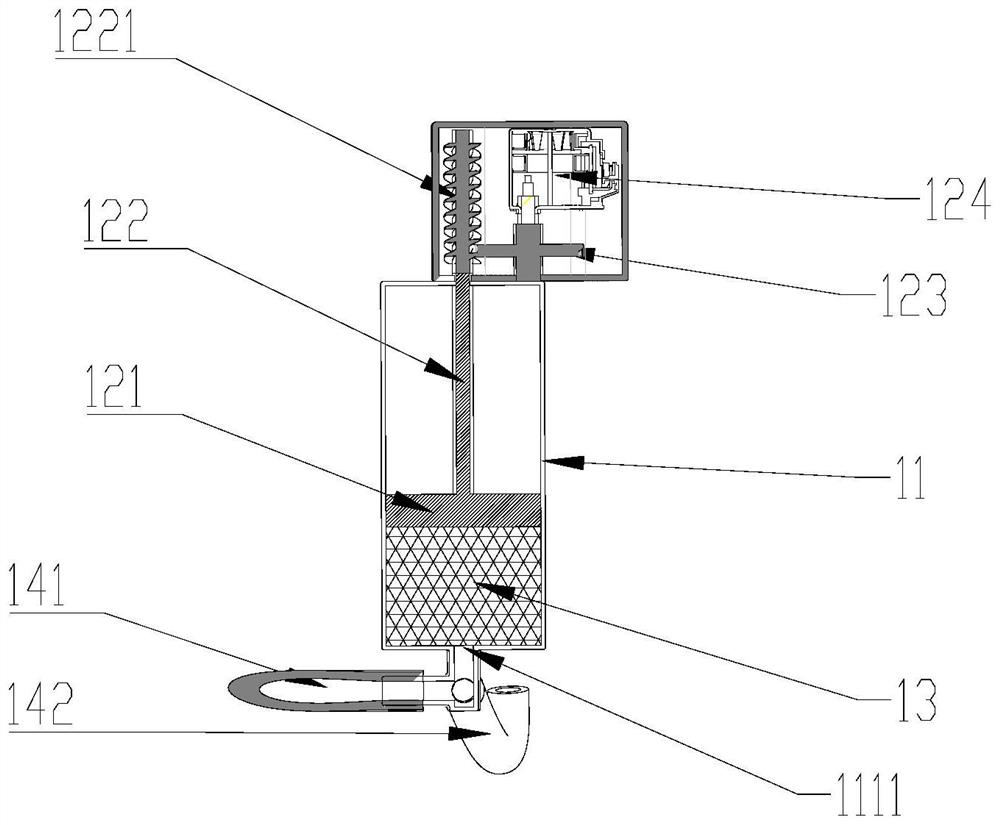

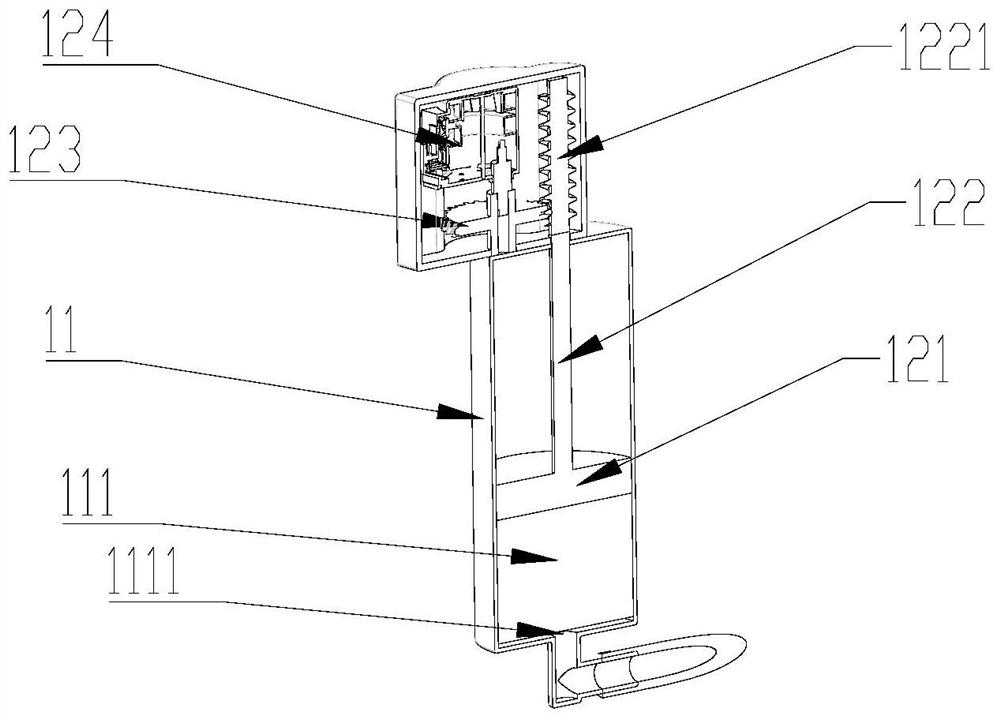

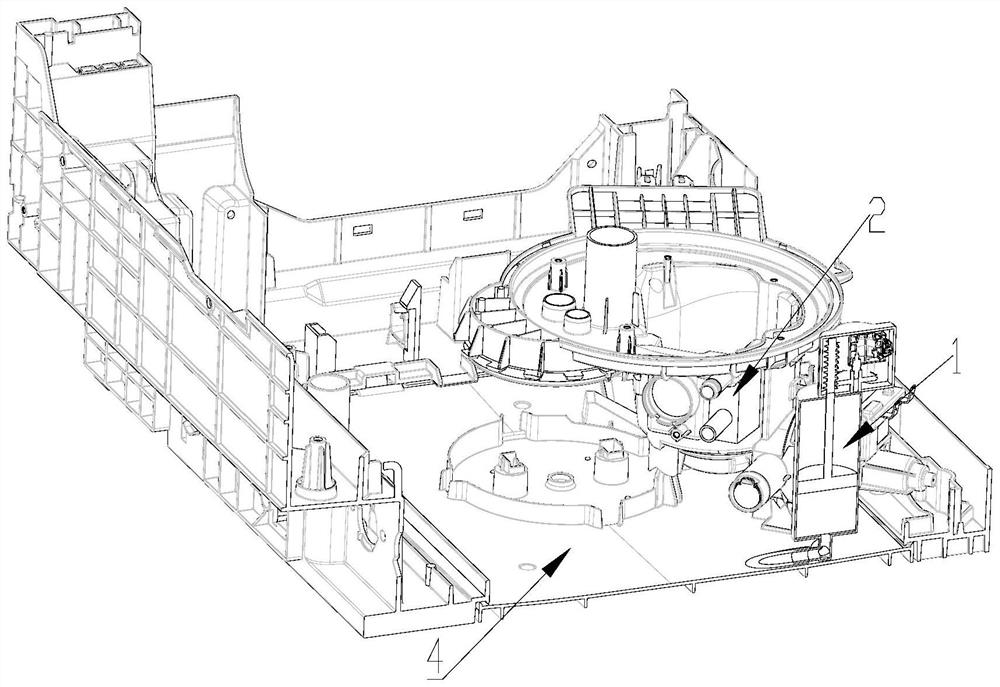

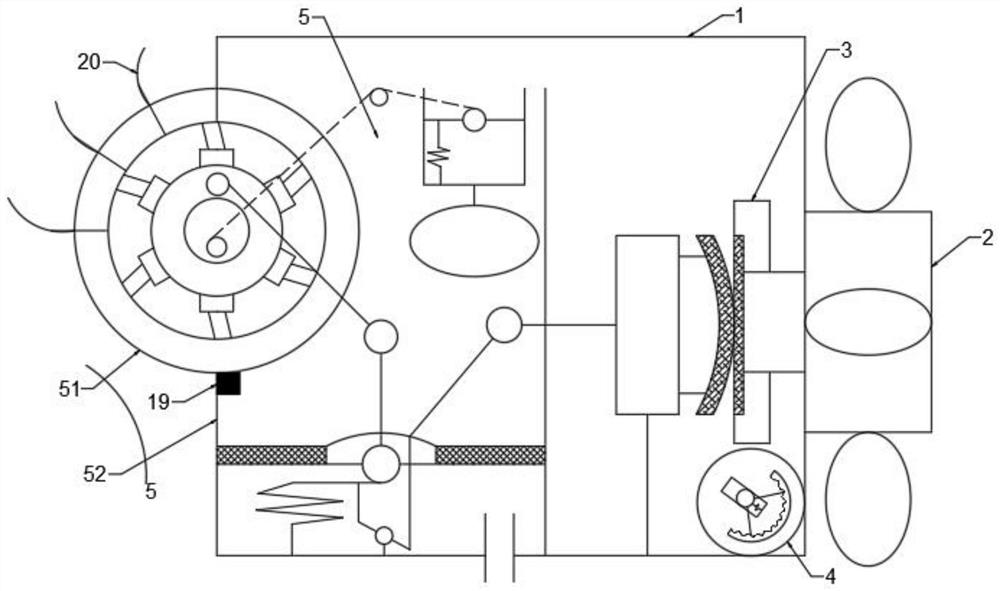

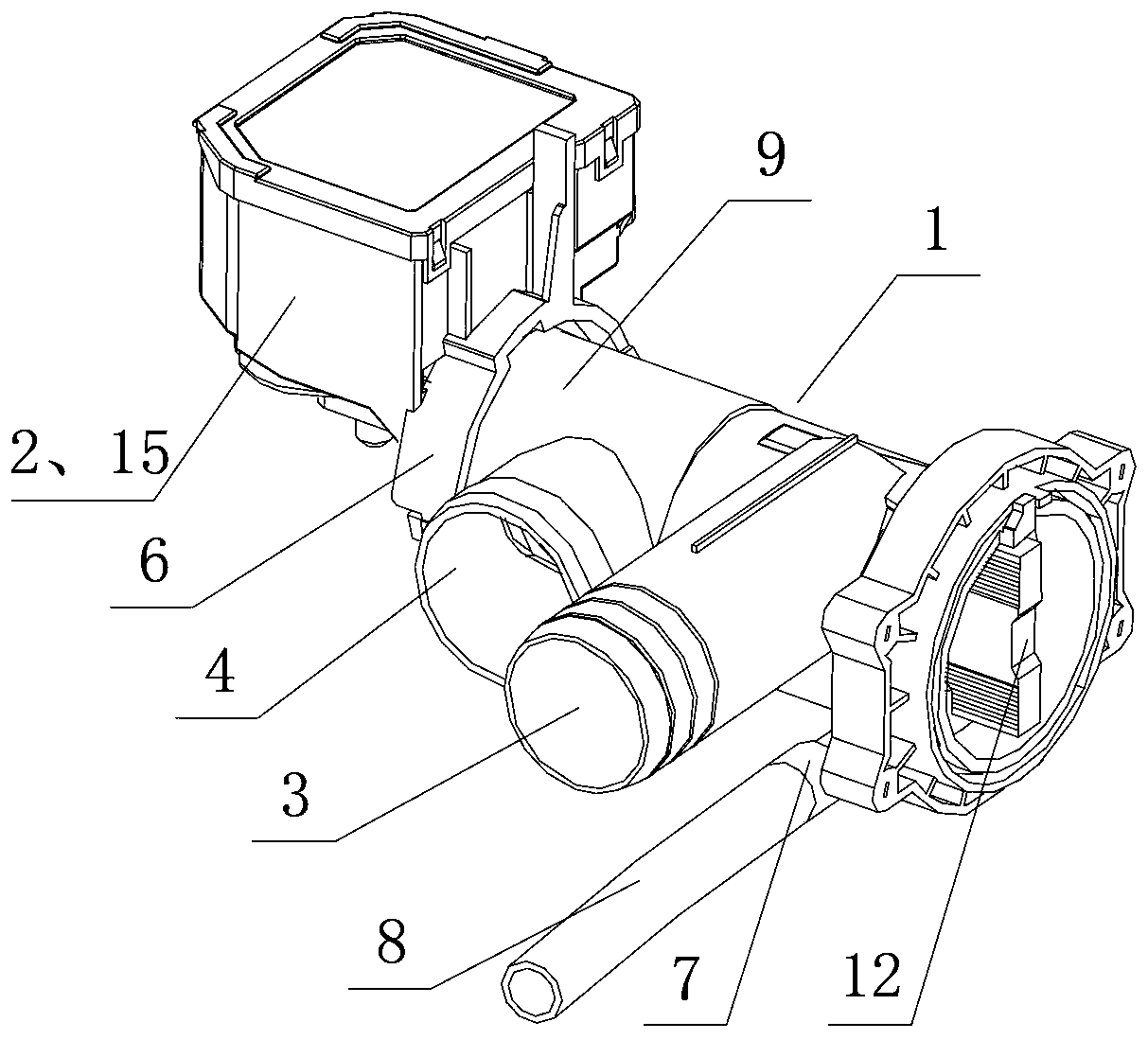

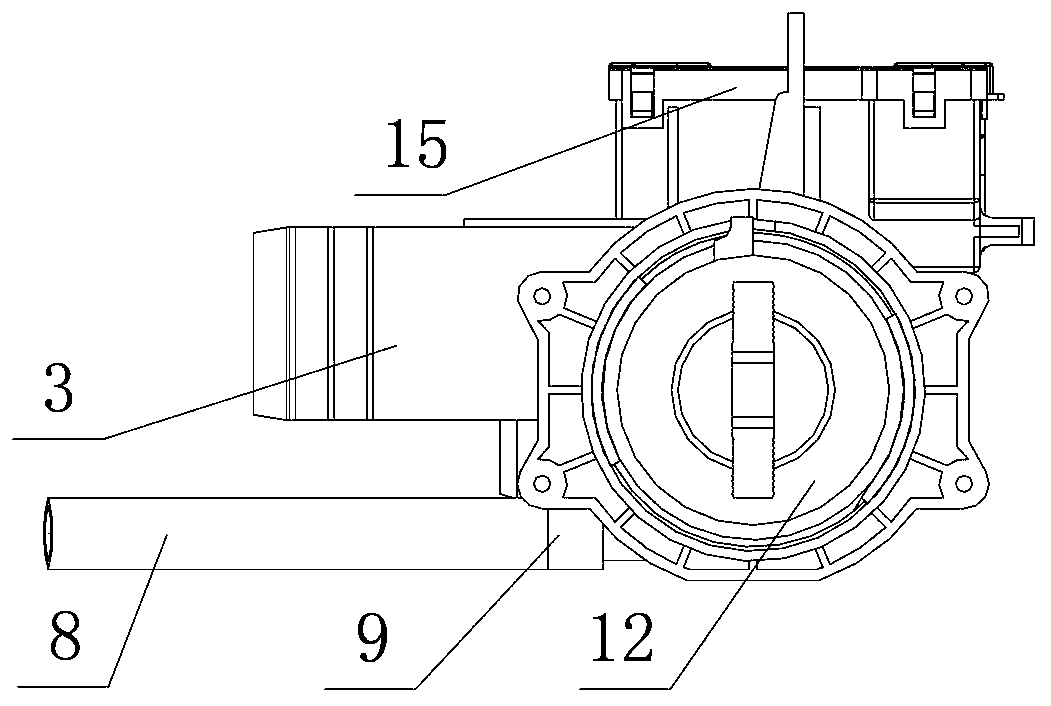

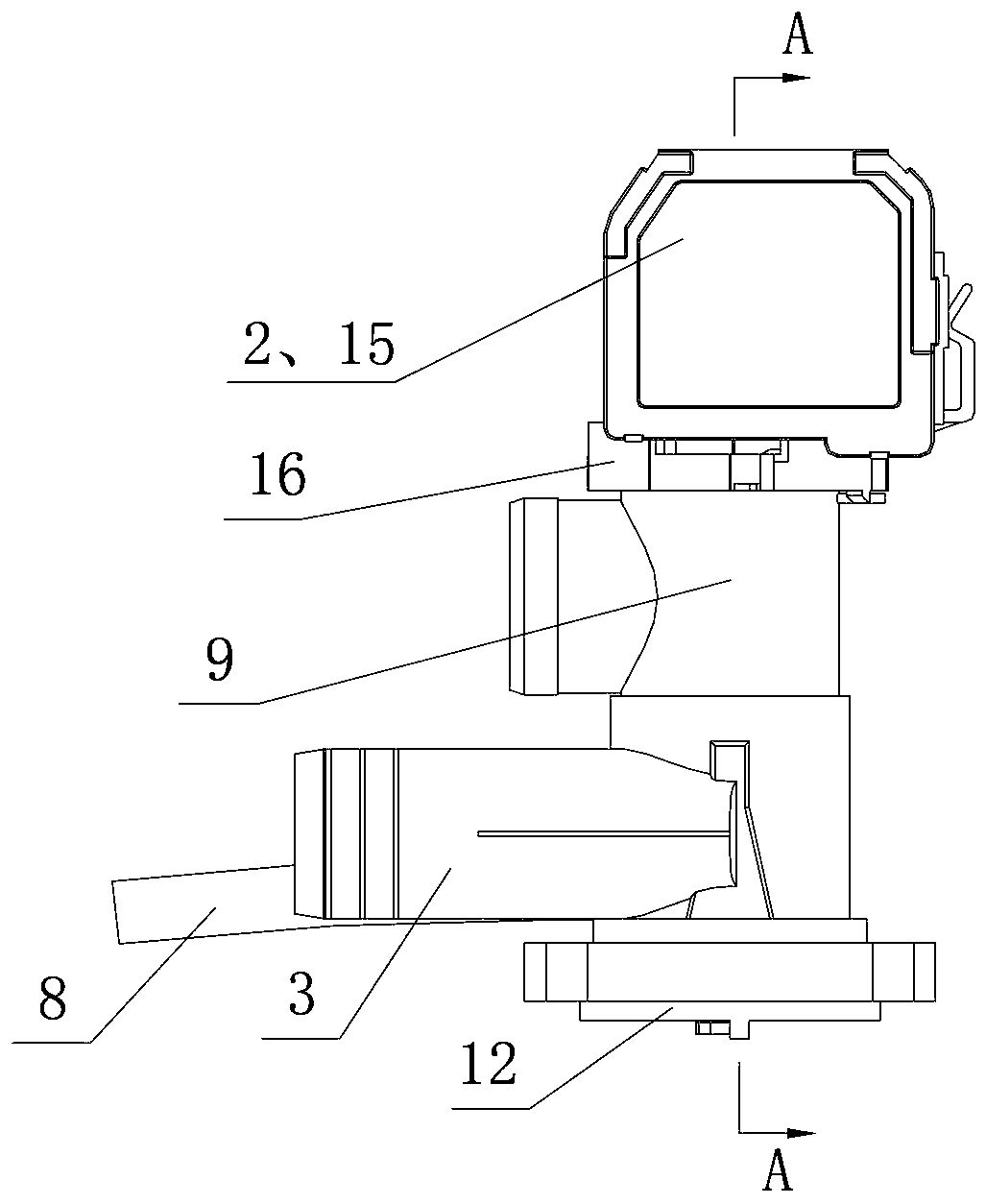

Integrated drainage component and washing machine

ActiveCN104294546ACompact structureSimplify the installation processOther washing machinesTextiles and paperFailure rateMechanical engineering

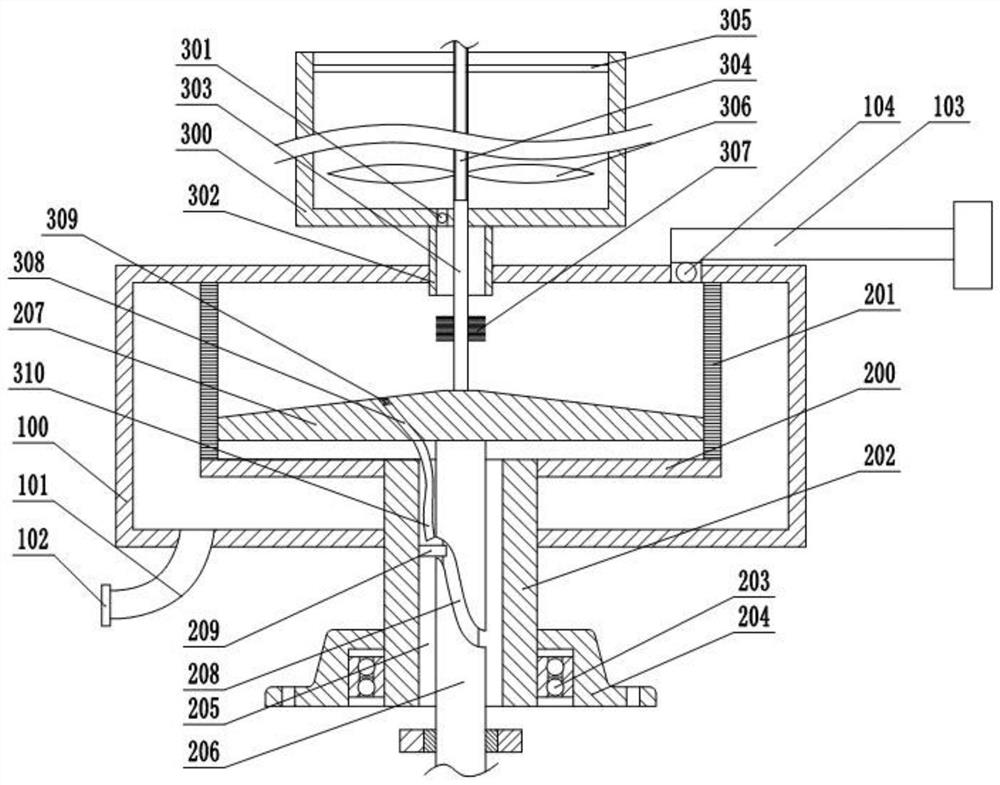

The invention relates to an integrated drainage component and a washing machine. The integrated drainage component comprises a drainage valve and a drainage motor, the drainage valve comprises a valve body and a valve cover, the drainage motor comprises a waterproof box, a drainage motor body is arranged in the waterproof box, the valve cover and the waterproof box are integrated, the drainage motor is detachably connected with the valve body through the valve cover, and an emergency drain outlet is further formed in a filter cavity. The drainage valve, the drainage motor, a filter and an emergency drainage pipeline are integrated, the structure is compact, installation is simple, cost is lowered, drainage noise is lowered, and the failure rate is lowered.

Owner:QINGDAO HAIER DRUM WASHING MACHINE

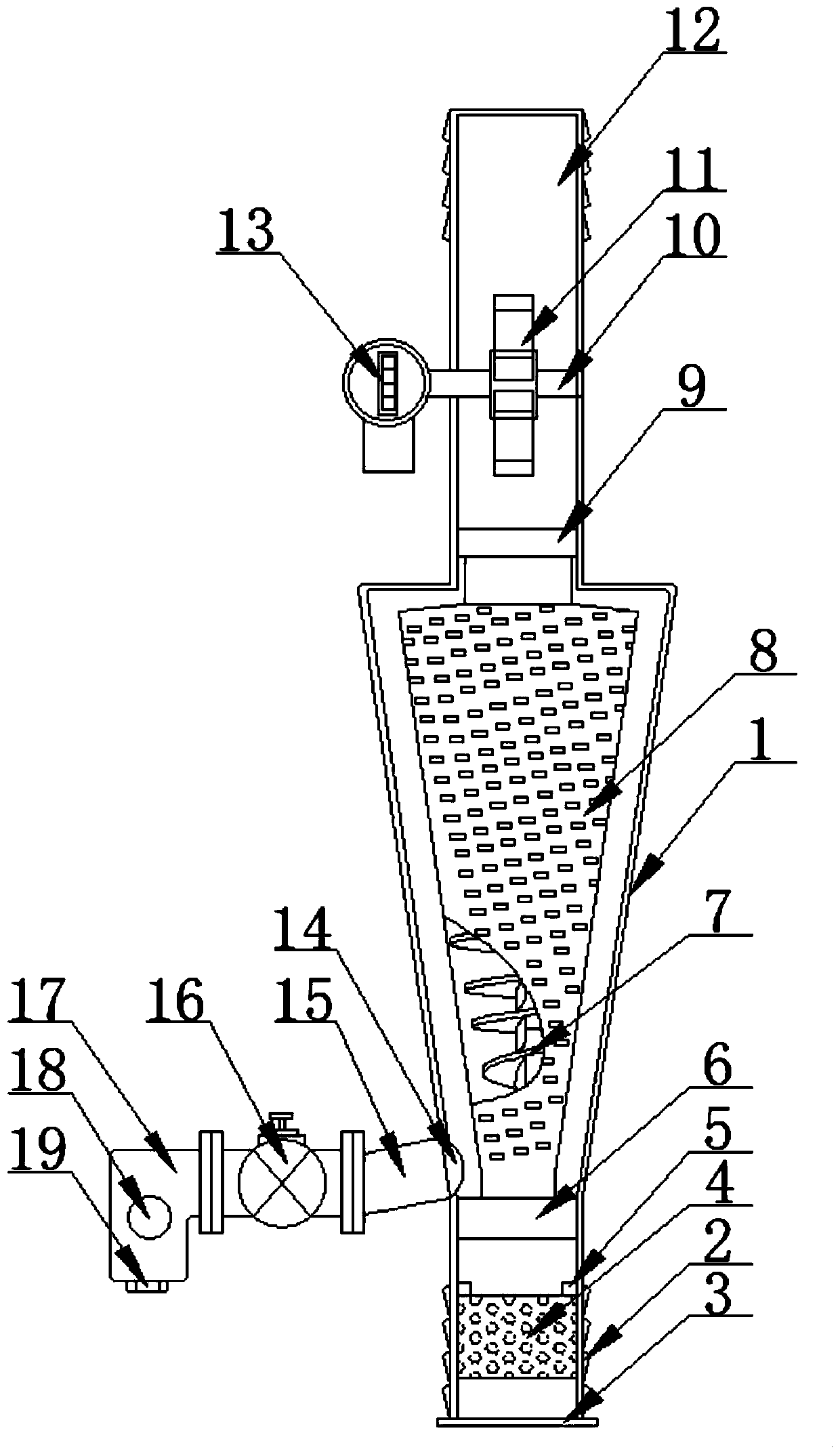

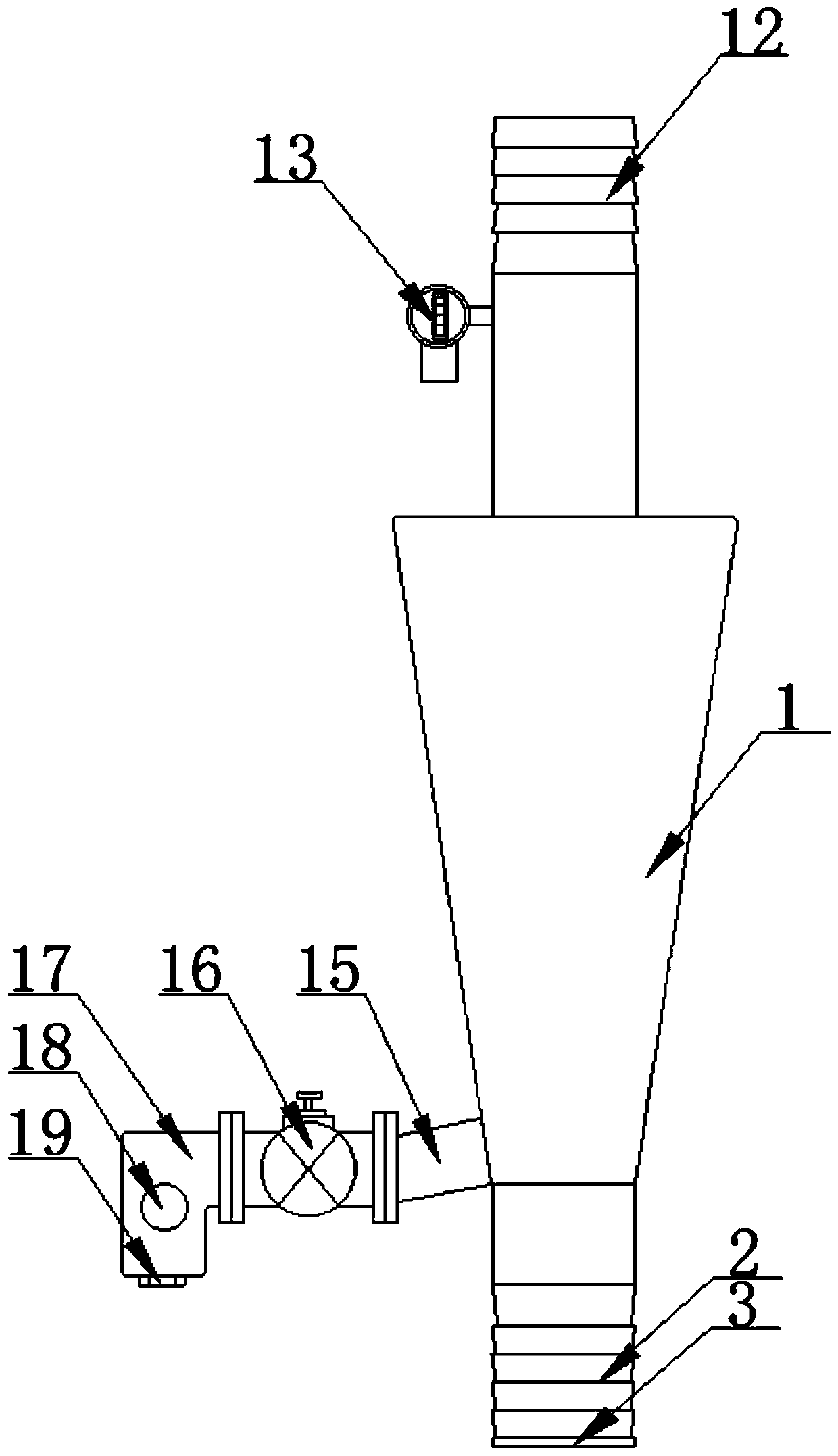

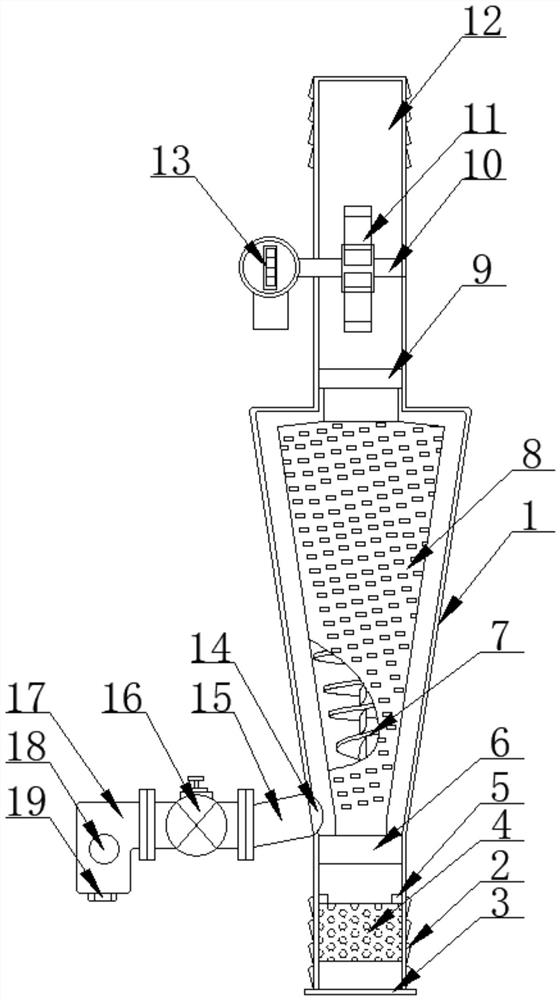

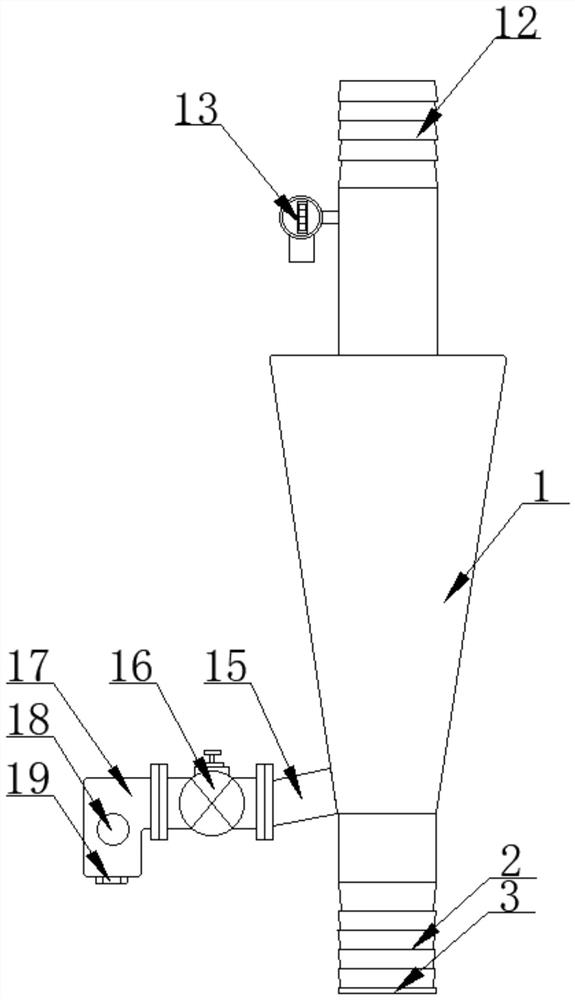

Oil production well hot washing liquid filtering device

ActiveCN110772858AQuick clean upImprove filtering effectStationary filtering element filtersOil productionEngineering

The invention discloses an oil production well hot washing liquid filtering device, and specially relates to the field of well washing tools. The device comprises a conical outer cylinder body, wherein an inlet end inverted pulling head and an outlet end inverted pulling head are installed at the two ends of the outer cylinder body, a large pore size filtering cylinder and an inlet fixing seat arearranged in the inlet end inverted pulling head, an impurity liquid separation cylinder is installed in the inlet fixing seat and an outlet fixing seat, a communicating hole is formed in one side ofthe outer cylinder body, and an impurity discharging flange, a valve body and an impurity settling box are installed on one side of the outer cylinder body. According to the invention, by arranging the conical impurity liquid separation cylinder and the conical spiral blade, after a washing fluid enters the washing fluid filtering device, the inclined centrifugal force is formed in the tangentialdirection of the periphery of the cylinder body through the conical impurity liquid separation cylinder and the conical spiral blade, and is gradually increased along the outlet direction, so that thegravels with various particle sizes in the washing fluid are thrown out of the impurity liquid separation cylinder due to the great centrifugal force so as to be separated from the washing fluid, andthe washing fluid mixed with the small-particle stratum sand can be well filtered.

Owner:孙雨飞

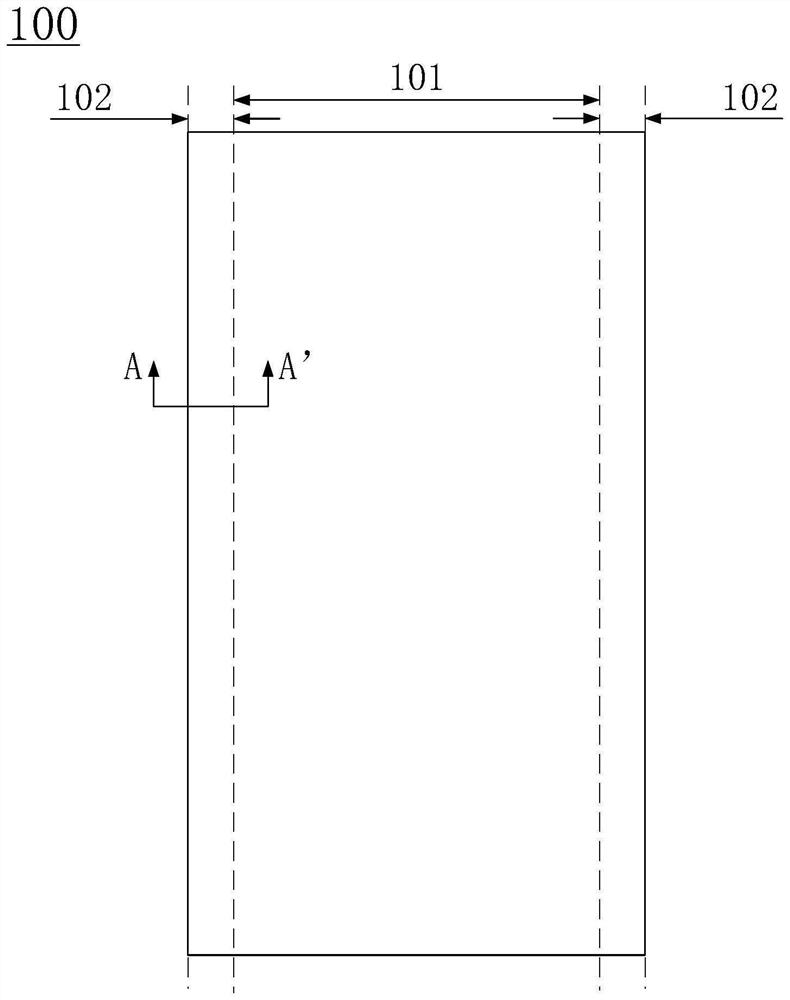

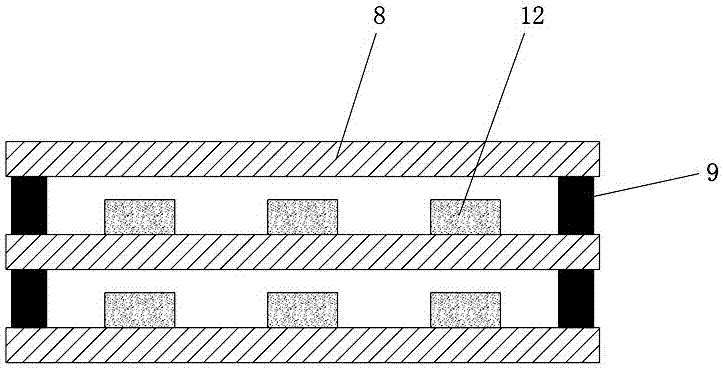

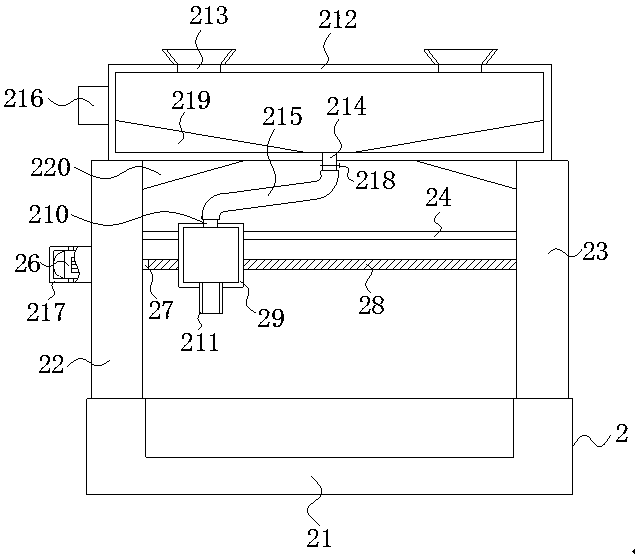

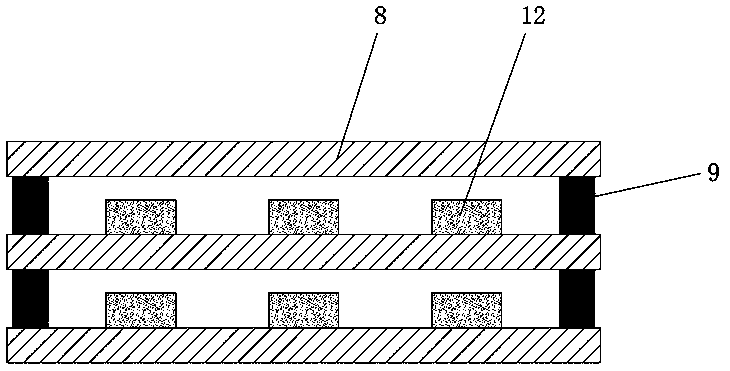

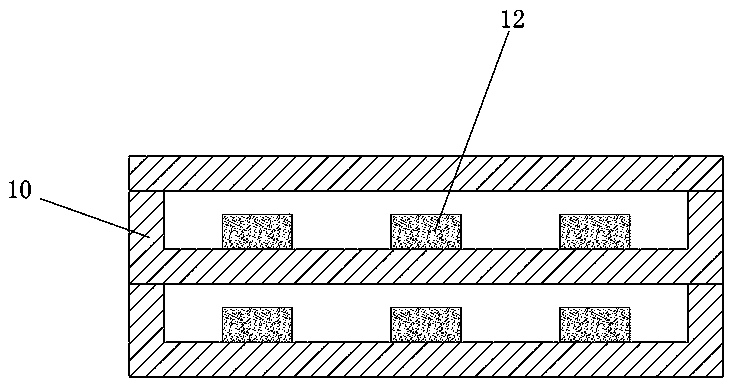

Display device

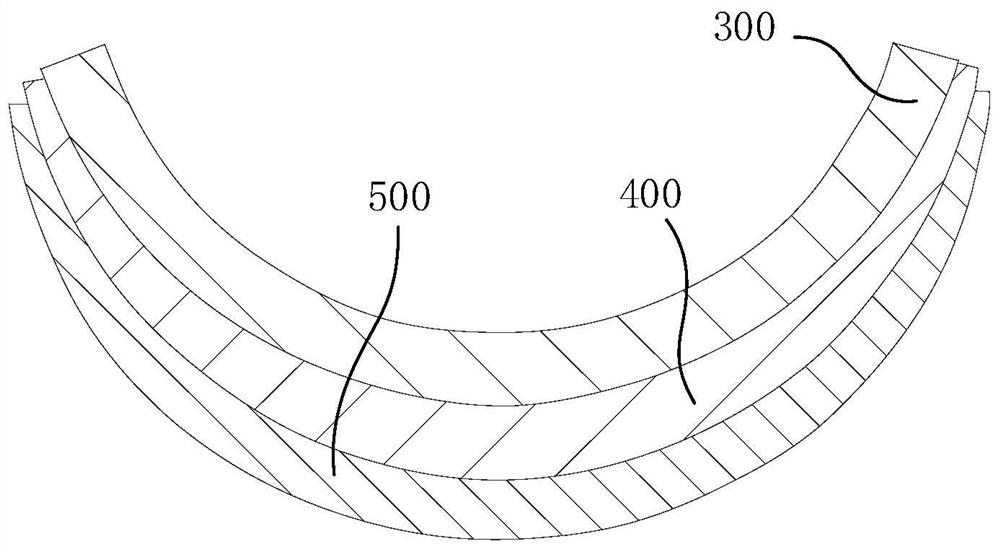

PendingCN114495719AAvoid being unable to dischargeImprove fit qualityIdentification meansDisplay deviceEngineering

The invention relates to a display device. The display device comprises a display panel and a cover plate, the bonding layer is arranged between the display panel and the cover plate, and the bonding layer comprises a first bonding part located in the plane area and a second bonding part located in the curved surface area; in the thickness direction of the display panel, the thickness of the first bonding part is larger than that of the second bonding part. According to the display device provided by the embodiment of the invention, bubbles can be prevented from occurring when the display panel and the cover plate are laminated, so that the laminating quality and the product yield are improved.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

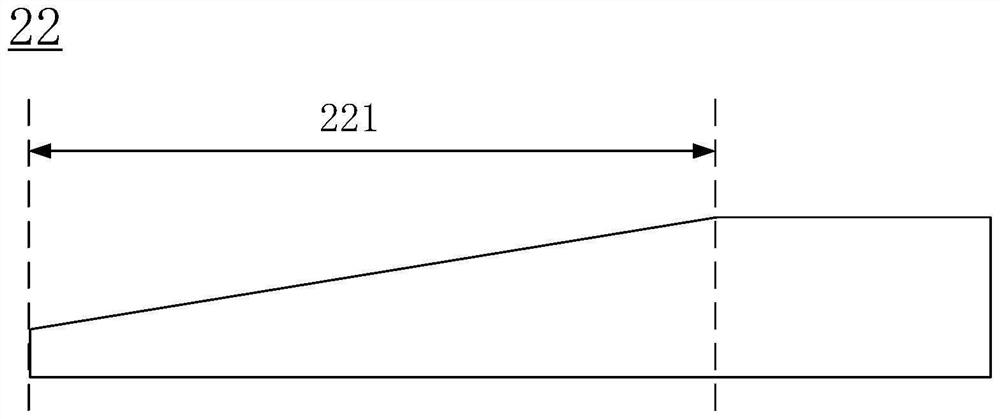

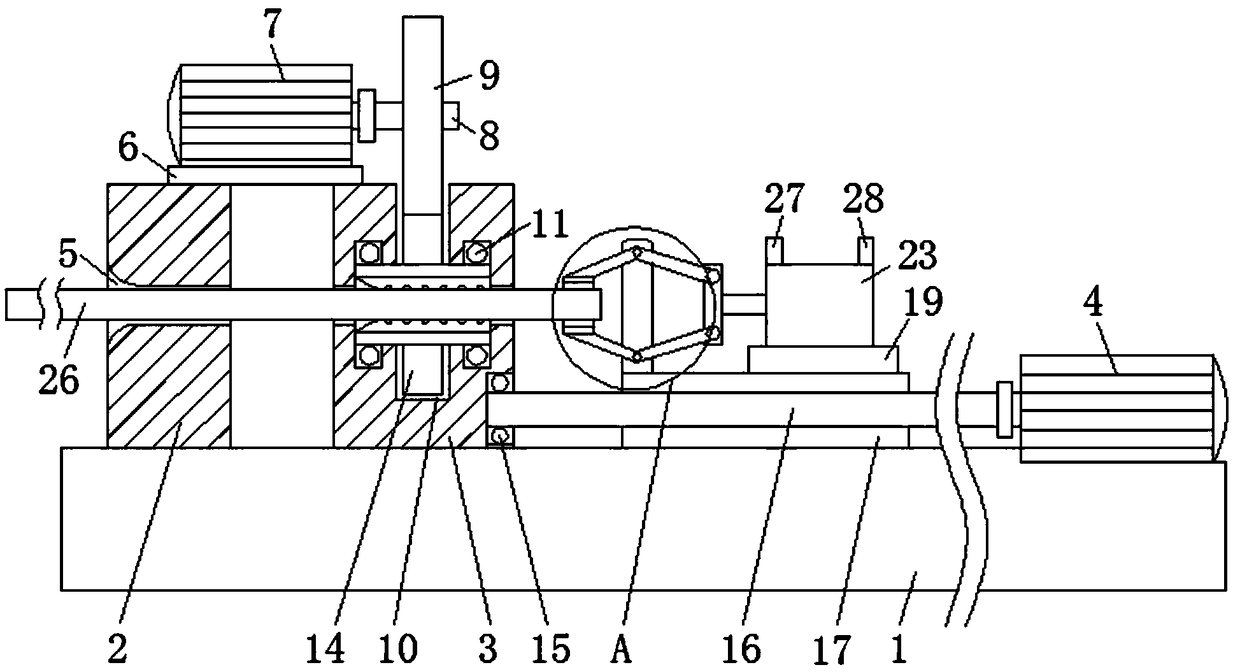

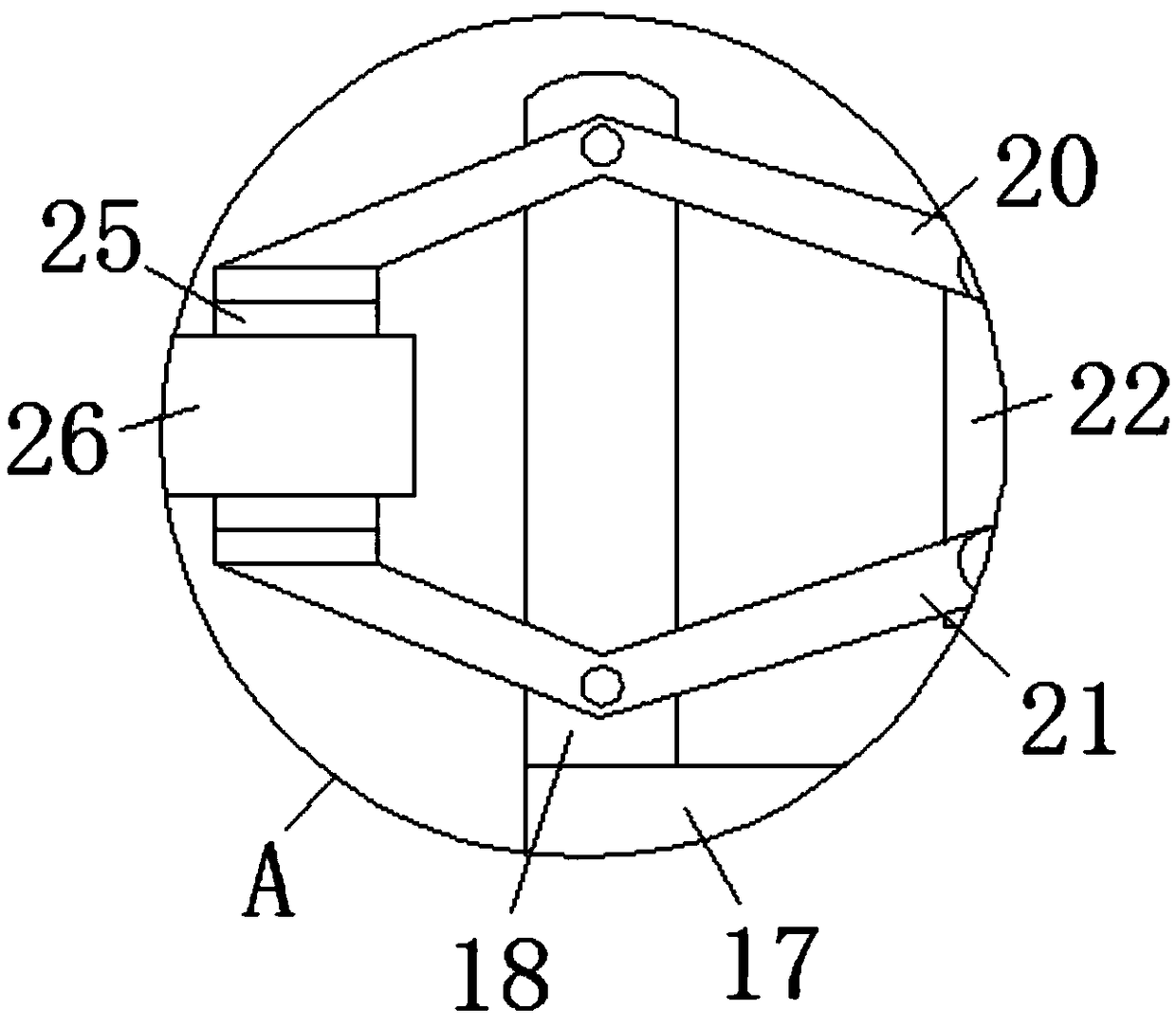

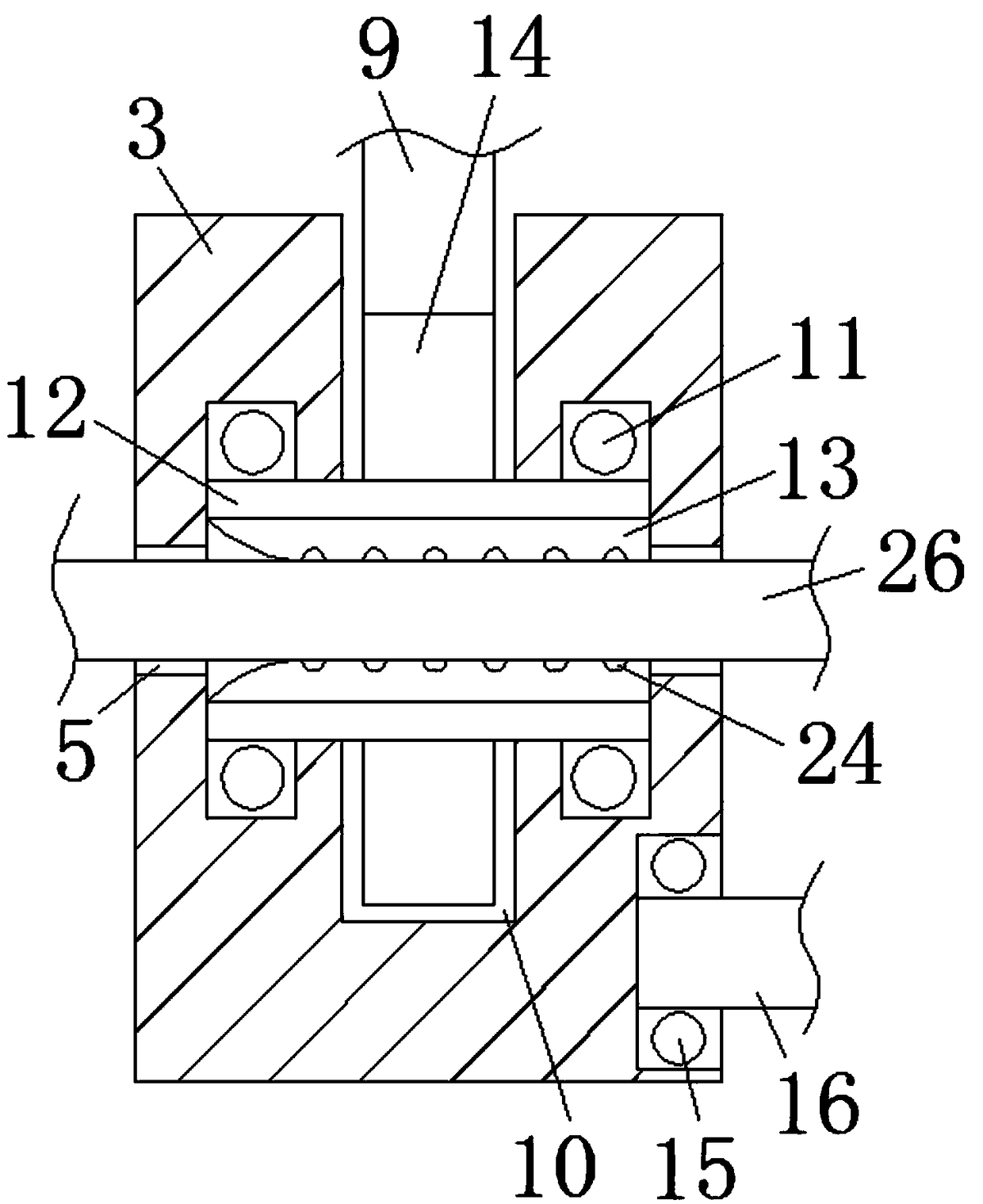

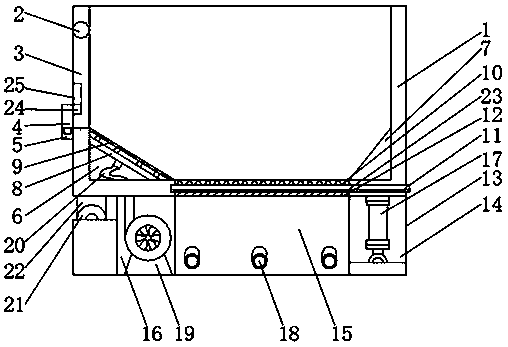

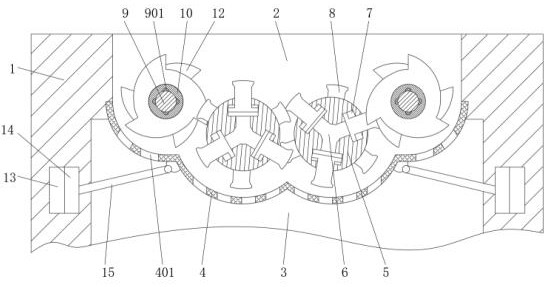

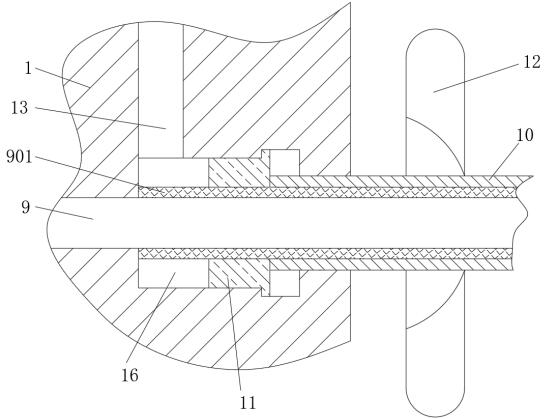

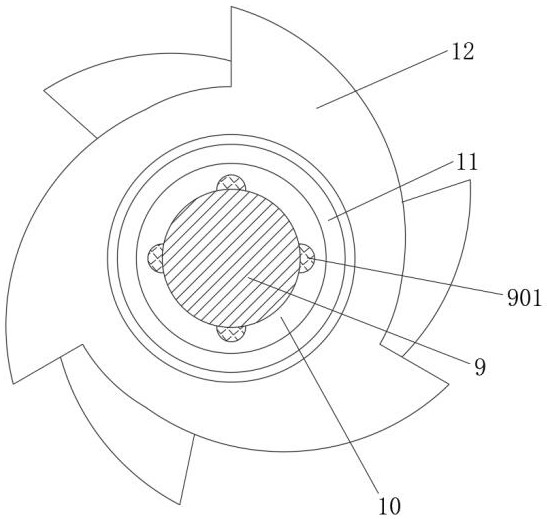

Copper bar combined drawing machine

InactiveCN108097729ATo achieve the effect of rotary polishingReduce material wasteRevolution surface grinding machinesSurface finishCoupling

The invention discloses a copper bar combined drawing machine. The copper bar combined drawing machine comprises an operating table, wherein the upper surface of the operating table is fixedly connected to a first positioning plate, a second positioning plate and a first motor, separately; material guiding holes are formed in the first positioning plate and the second positioning plate; the uppersurfaces of the first positioning plate and the second positioning plate are fixedly connected to a first base; the upper surface of the first base is fixedly connected to a second motor; and the output shaft of the second motor is fixedly connected to a rotary shaft through a coupling. The copper bar combined drawing machine disclosed by the invention achieves an effect of rotatably polishing thesurface of a copper bar body, so that material waste of the copper bar body is reduced; the copper bar body can be drawn; the copper bar combined drawing machine can avoid the problem that copper scales ground by millstones cannot be discharged effectively, and can enhance the drawing effects of an upper manipulator and a lower manipulator on the surface of the copper bar body effectively, so that the problem that materials are easily wasted for surface smoothness treatment of a common drawing machine is solved effectively.

Owner:贵溪静星信息技术服务有限公司

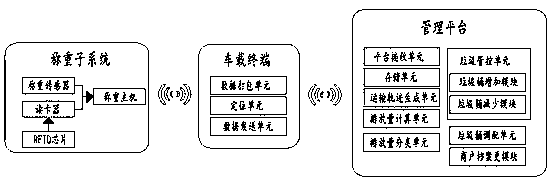

Intelligent management control system for urban garbage

ActiveCN110255016AAvoid being unable to dischargeTimely warningRefuse vehiclesControl systemEmission standard

The invention relates to the technical field of urban garbage management control, and specifically relates to an intelligent management control system for urban garbage. The system comprises a weighing subsystem, a vehicle-mounted terminal and a management platform, wherein the weighing subsystem is used for acquiring identity information and garbage weight of a garbage can; the identity information includes the number of the garbage can; the vehicle-mounted terminal is used for receiving data of the weighing subsystem and packing and sending the number of each garbage can and the garbage weight corresponding to the garbage can to the management platform; and the management platform comprises a garbage management control system which is used for selecting one commercial tenant from emission standard exceeding class or insufficient emission class as a target commercial tenant based on the sequence, acquiring a commercial tenant following the target commercial tenant as an adjacent commercial tenant based on the location information of the commercial tenant and performing management control on the garbage can of the commercial tenant based on the class of the adjacent commercial tenant. With the adoption of the system, the management control effect of the urban garbage can resource distribution is improved, and the urban garbage can utilization efficiency is also improved.

Owner:CHONGQING ENVIRONMENT & SANITATION GRP CO LTD

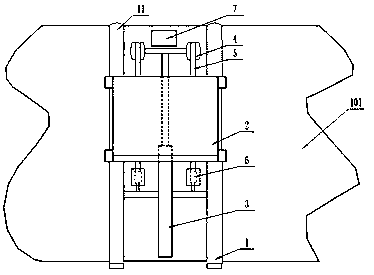

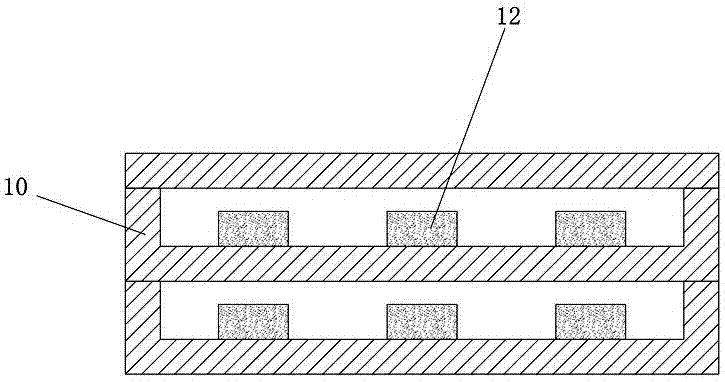

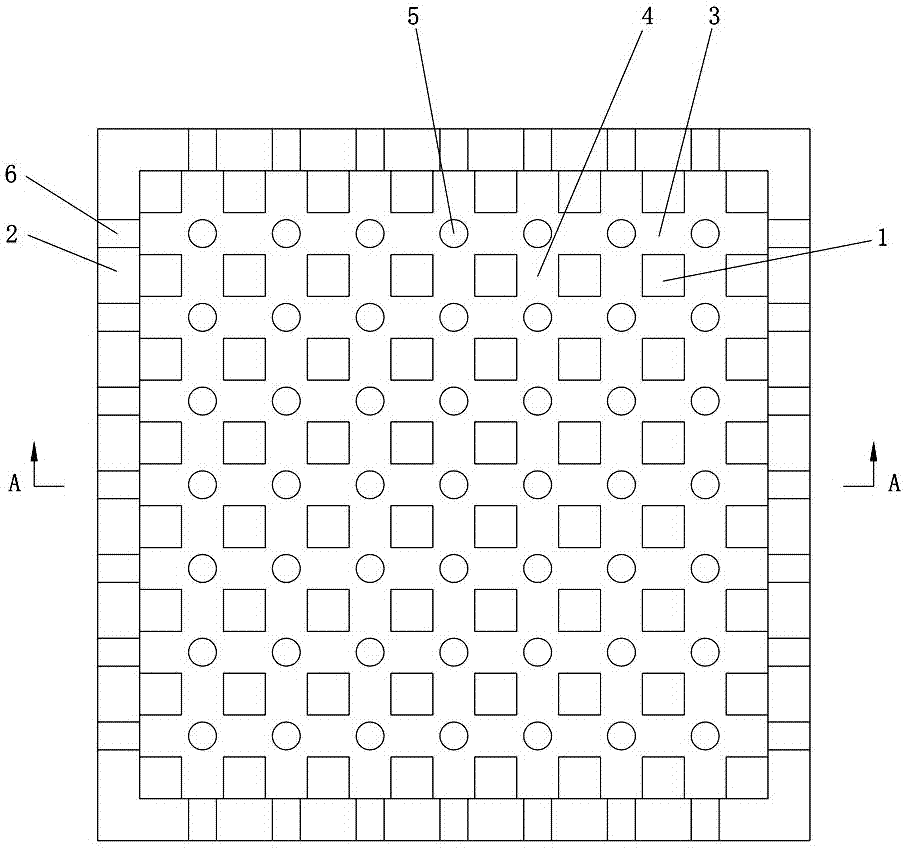

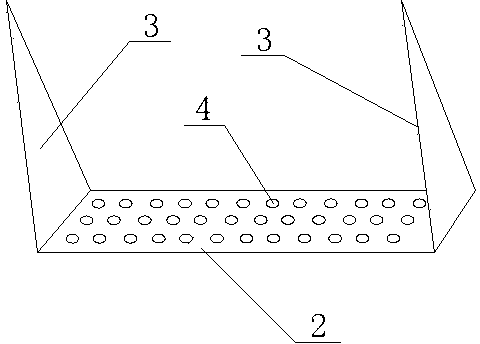

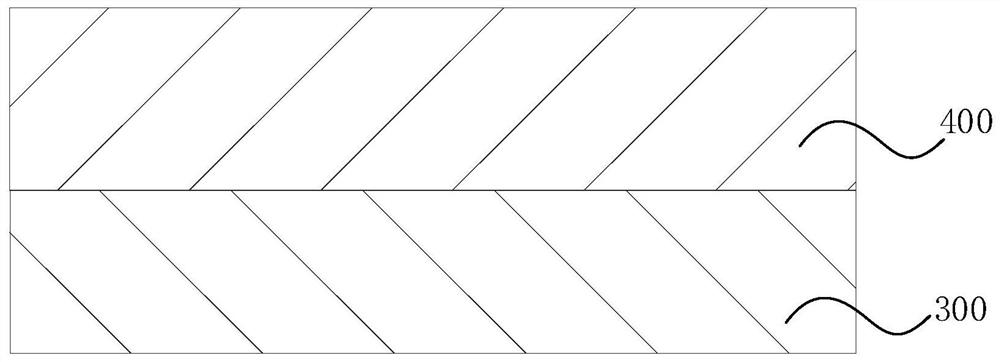

Boat and boat group for hard alloy dewaxing process

The invention discloses a boat and boat group for a hard alloy dewaxing process. The boat for the hard alloy dewaxing process comprises a bottom plate and a side wall; the side wall is enclosed at the outer edge of the obverse side of the bottom plate; more than one horizontal flow guide slot and more than one longitudinal flow guide slot are formed in the obverse side of the bottom plate; the horizontal flow guide slots are intersected with the longitudinal flow guide slots, and bottom plate through holes are formed in the bottom plate at the intersections; and more than one side wall through hole is formed in the side wall. The boat group comprises a cover plate and more than two groups of boats for the hard alloy dewaxing process, the boats are vertically stacked, and the cover plate covers the side wall of the boat located at the topmost layer. The boat and boat group for the hard alloy dewaxing process, disclosed by the invention, have the advantages of high dewaxing efficiency, stable product quality and the like.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

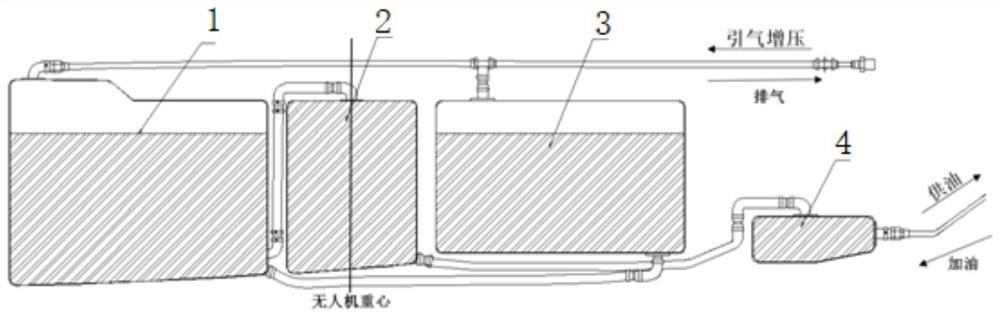

Series-parallel connection mixed oil way system for unmanned aerial vehicle

PendingCN111746807ALow costAvoid being unable to dischargePower plant fuel tanksMarine engineeringFuel tank

The invention discloses a series-parallel connection mixed oil way system for an unmanned aerial vehicle. The series-parallel connection mixed oil way system comprises a first oil tank, a second oil tank, a third oil tank and a consumption oil tank; the middle of the second oil tank is located at the gravity center of the unmanned aerial vehicle; an air pipe is simultaneously used as an exhaust port and an air entraining pressurizing port; the tops of the first oil tank and the third oil tank are connected with the same air pipe; the air entraining supercharging pressure is the same; the bottom of the first oil tank communicates with the bottom of the third oil tank through a pipeline; the bottom of the first oil tank communicates with the top of the second oil tank through a pipeline; thebottom of the second oil tank communicates with the top of the consumption oil tank through a pipeline; the volume of gas pressed into the fuel oil system by air entraining and pressurizing is largerthan the oil pumping volume of the oil pump; the oil loading capacity of the first oil tank and the third oil tank accounts for a large proportion of the total amount of fuel oil. The problem that air cannot be exhausted in the refueling process of the unmanned aerial vehicle is solved; in the flying process of the unmanned aerial vehicle, the stability margin of the unmanned aerial vehicle is changed due to gravity center change; engine flameout caused by the fact that air is sucked into the engine when the unmanned aerial vehicle does various maneuvering actions is avoided.

Owner:NO 60 RES INST OF GENERAL STAFF DEPT PLA

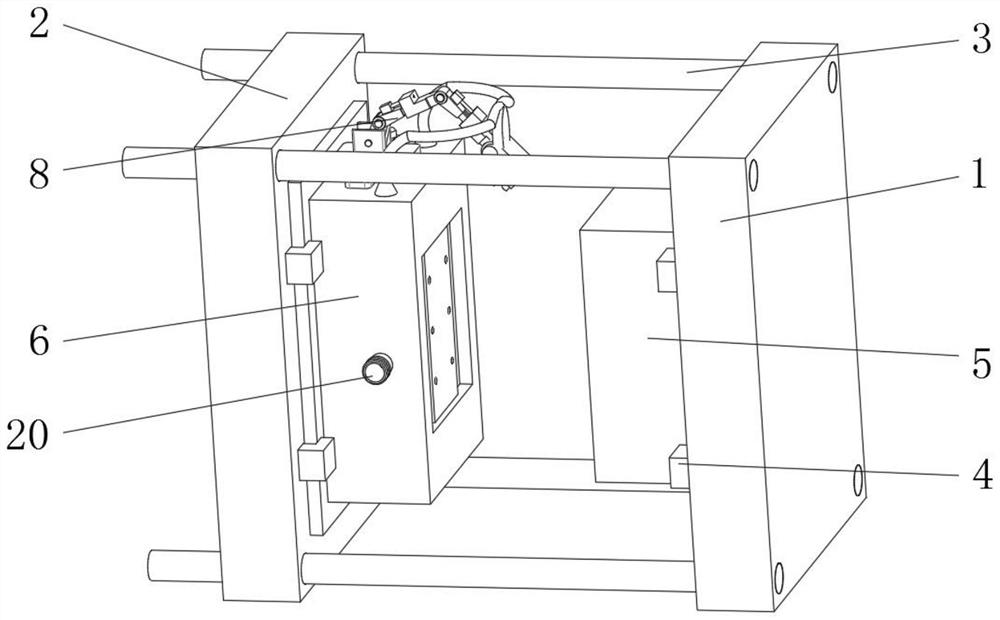

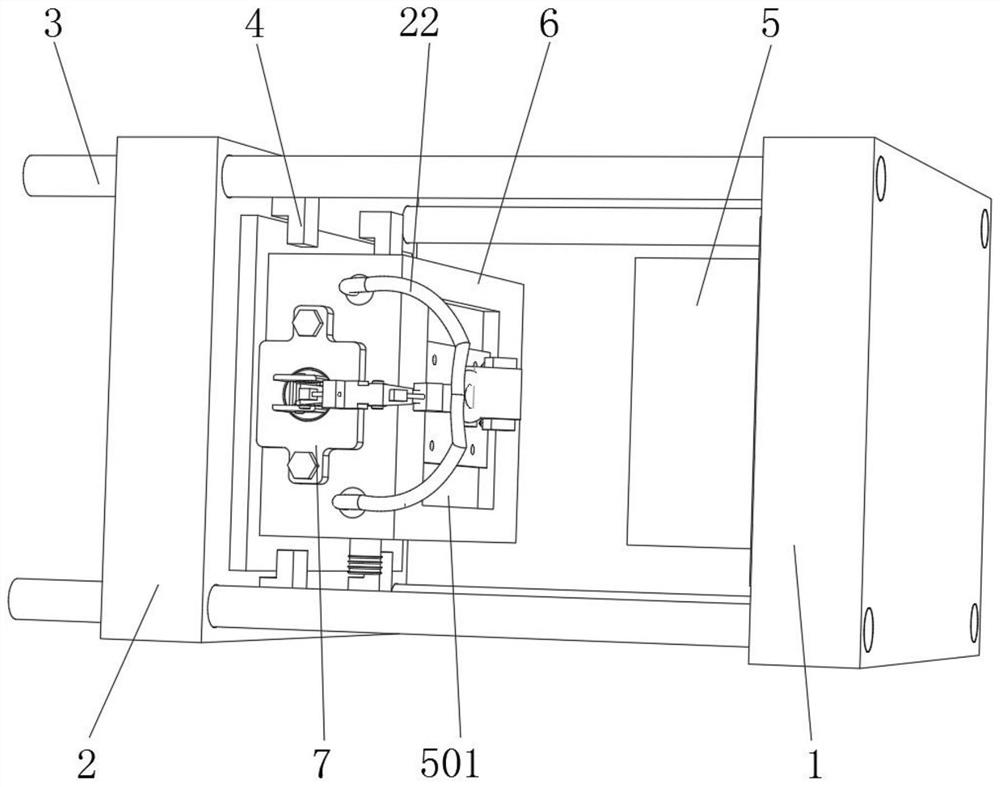

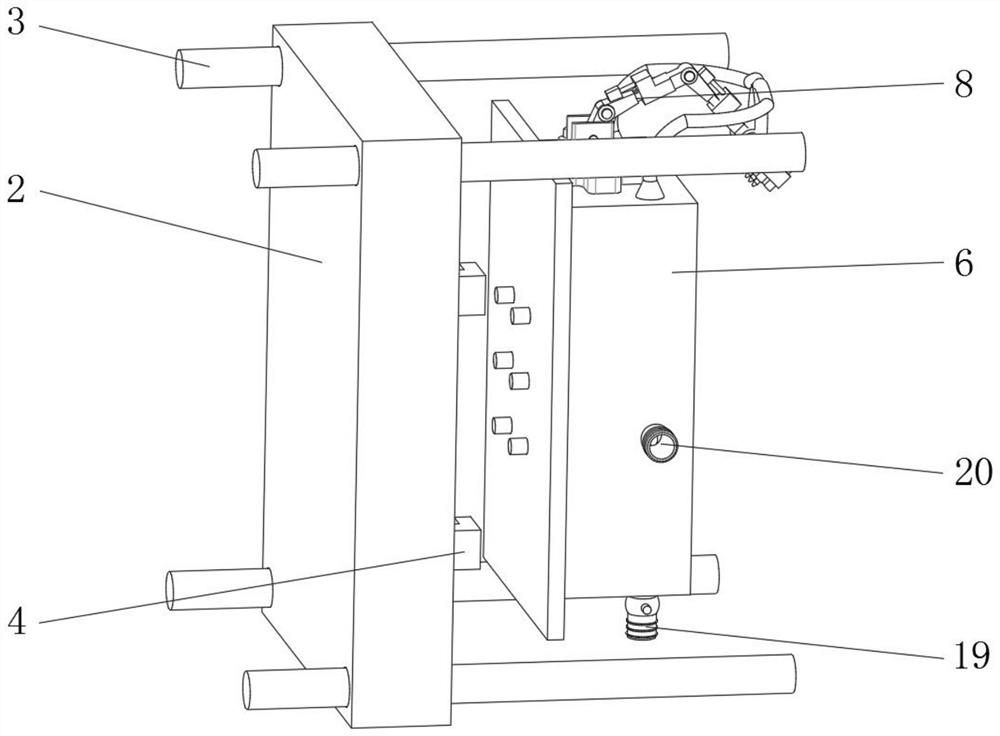

Die-casting die with cooling mechanism and using method of die-casting die

The invention relates to the technical field of die-casting dies, and discloses a die-casting die with a cooling mechanism and a using method of the die-casting die. The die-casting die comprises a fixed die insert and a movable die insert, the fixed die insert and the movable die insert are connected through a guide rod, and fixing pieces are arranged on the opposite circumferential sides of the fixed die insert and the movable die insert. According to the die-casting die with the cooling mechanism, after high-temperature liquid metal is injected into a die groove, a movable die is rapidly heated, cold water in a water storage cavity is rapidly heated and boiled to generate a large amount of steam, the steam is collected in a gas collection chamber, a separation pipe is used for separating water vapor from water, the water vapor is led into the gas collection chamber, the water flows back into the water storage cavity through through holes in a separator and is discharged through a water outlet, cold water is introduced through a water inlet formed above the bottom of the separation pipe all the time, so that part of water vapor in the separation pipe is liquefied into water when being cooled, and the damage to water cooling equipment caused by the fact that the water vapor and the water are discharged through the water outlet after being rapidly formed is avoided.

Owner:尚锟

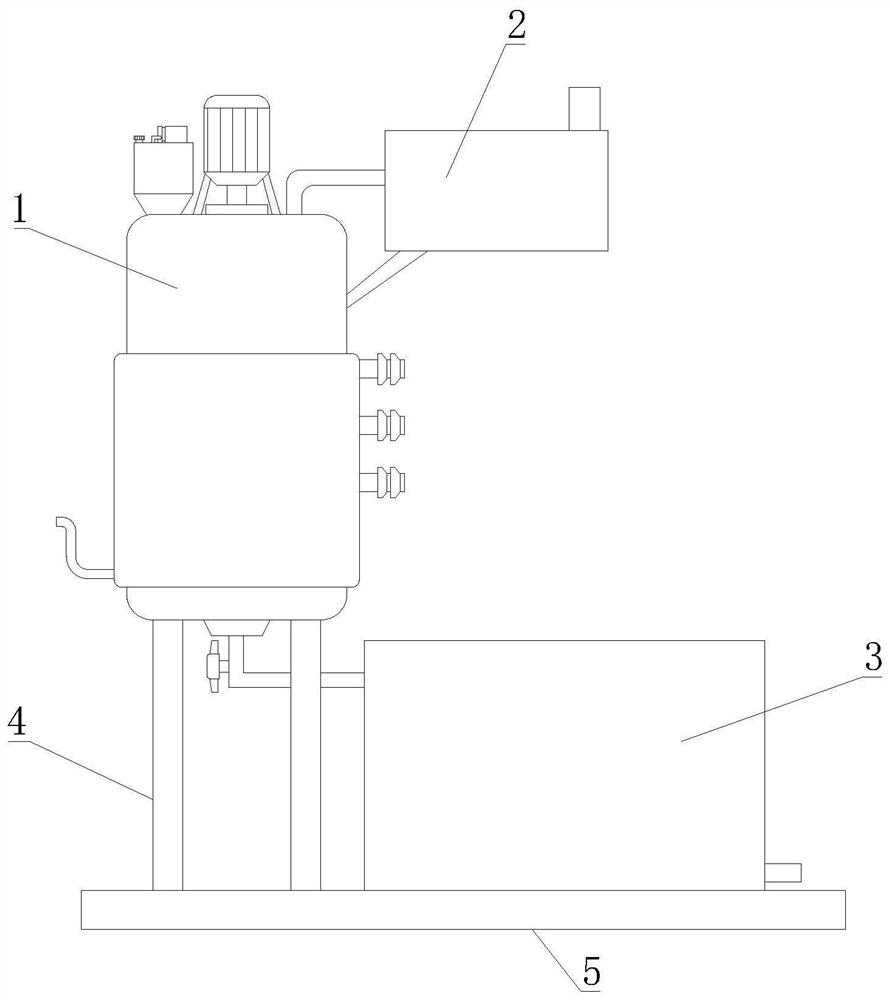

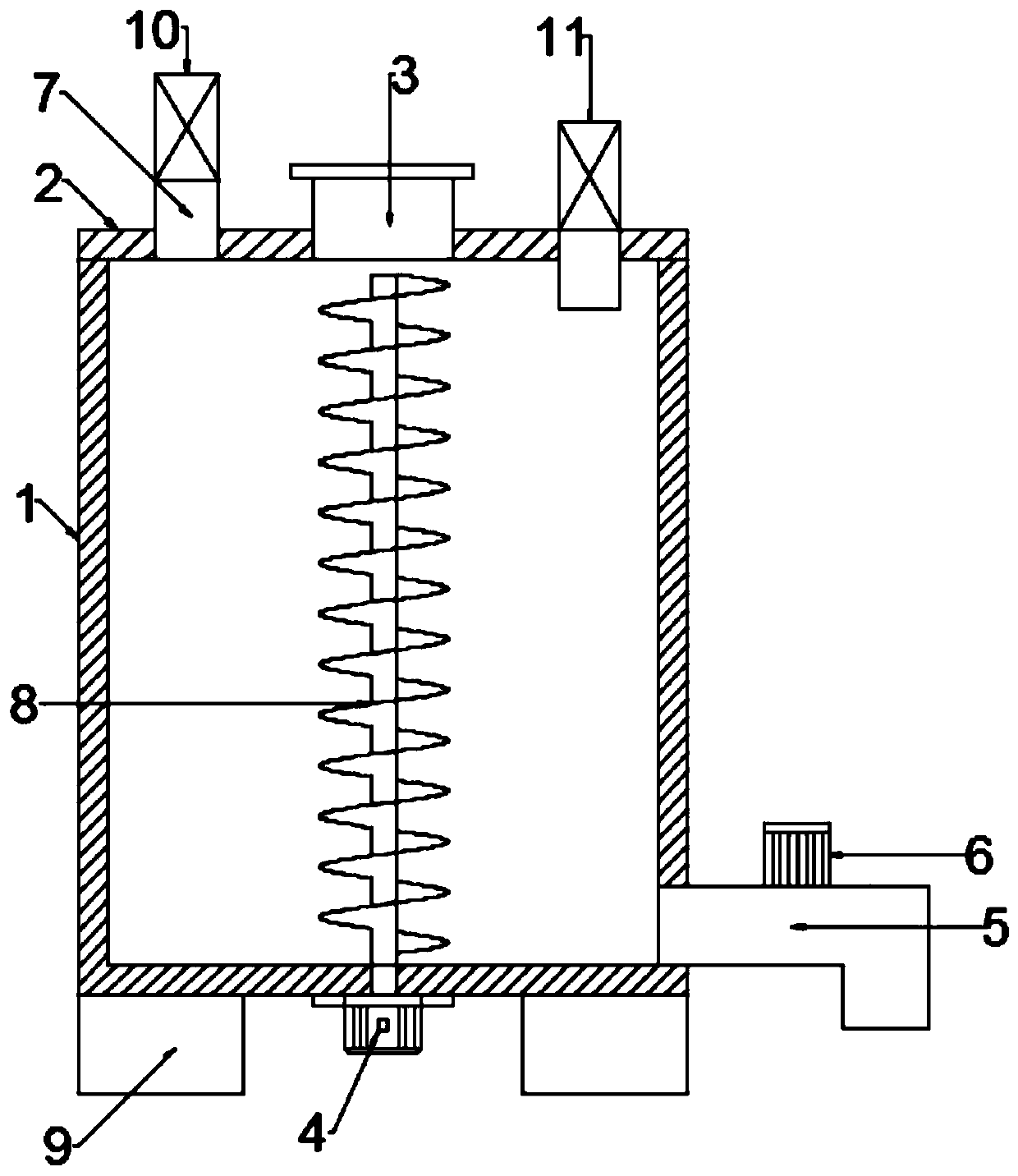

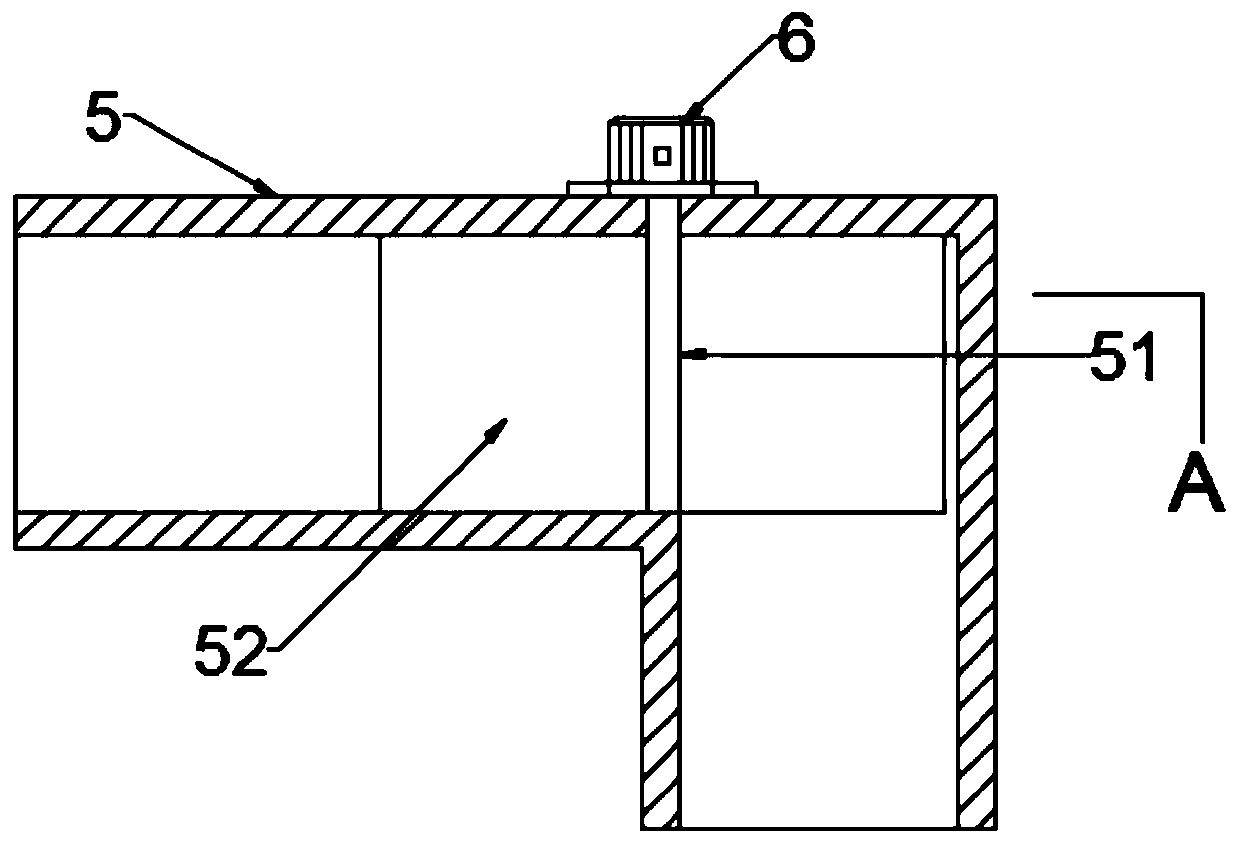

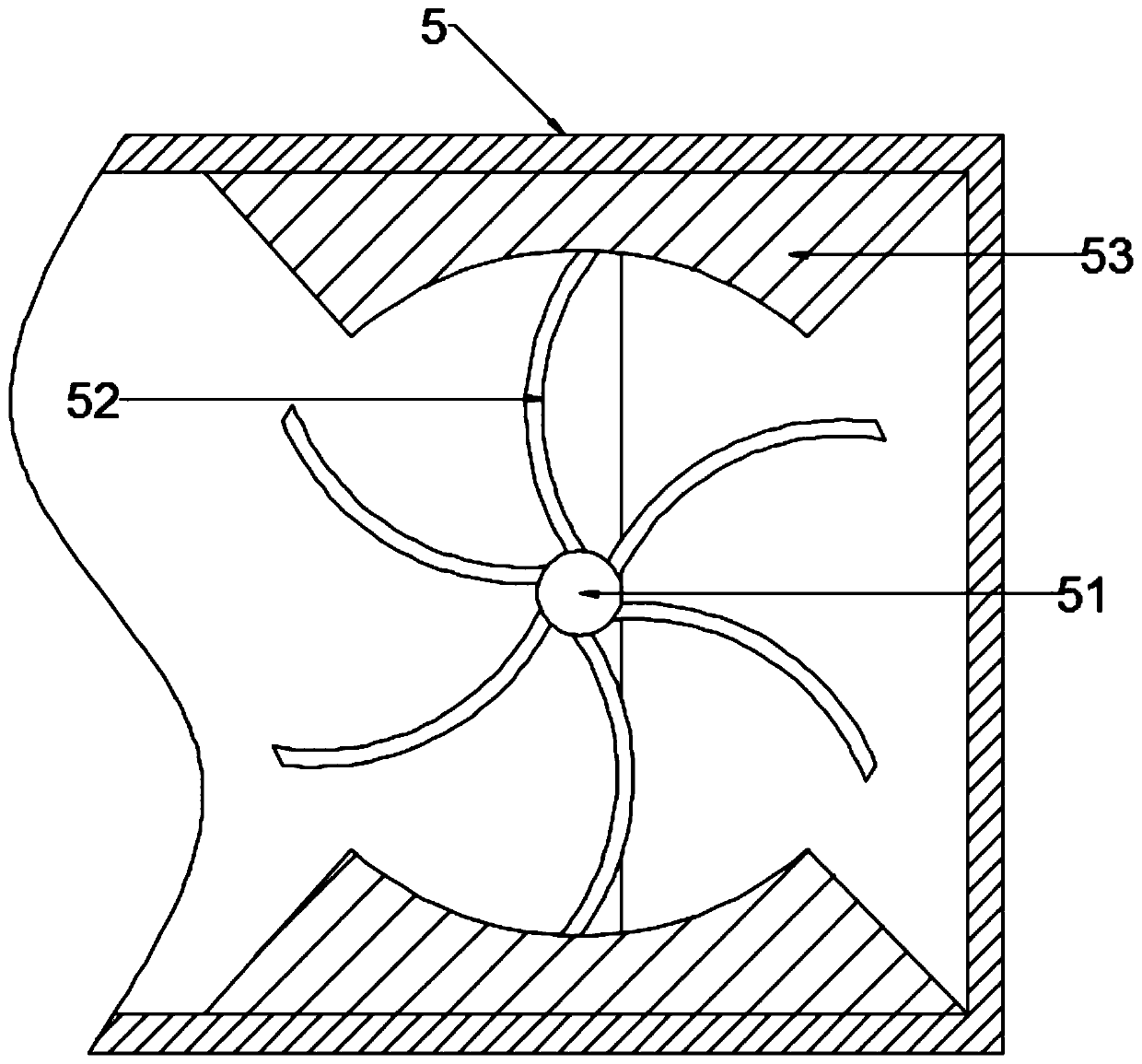

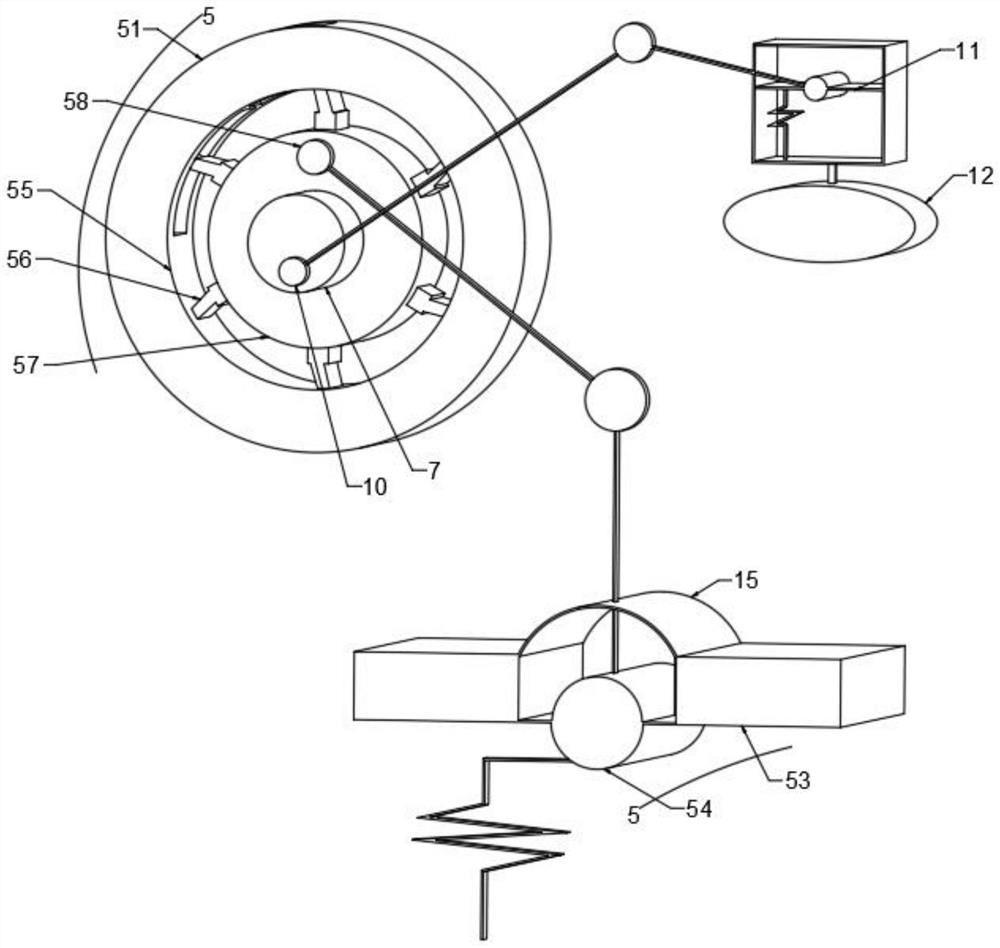

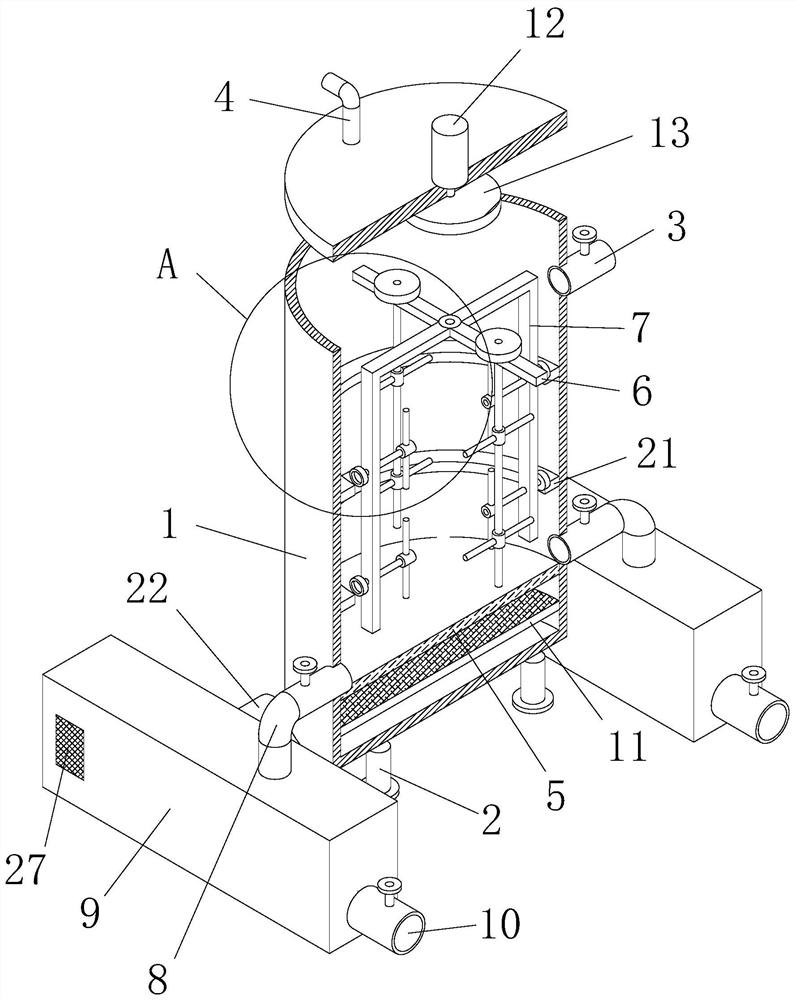

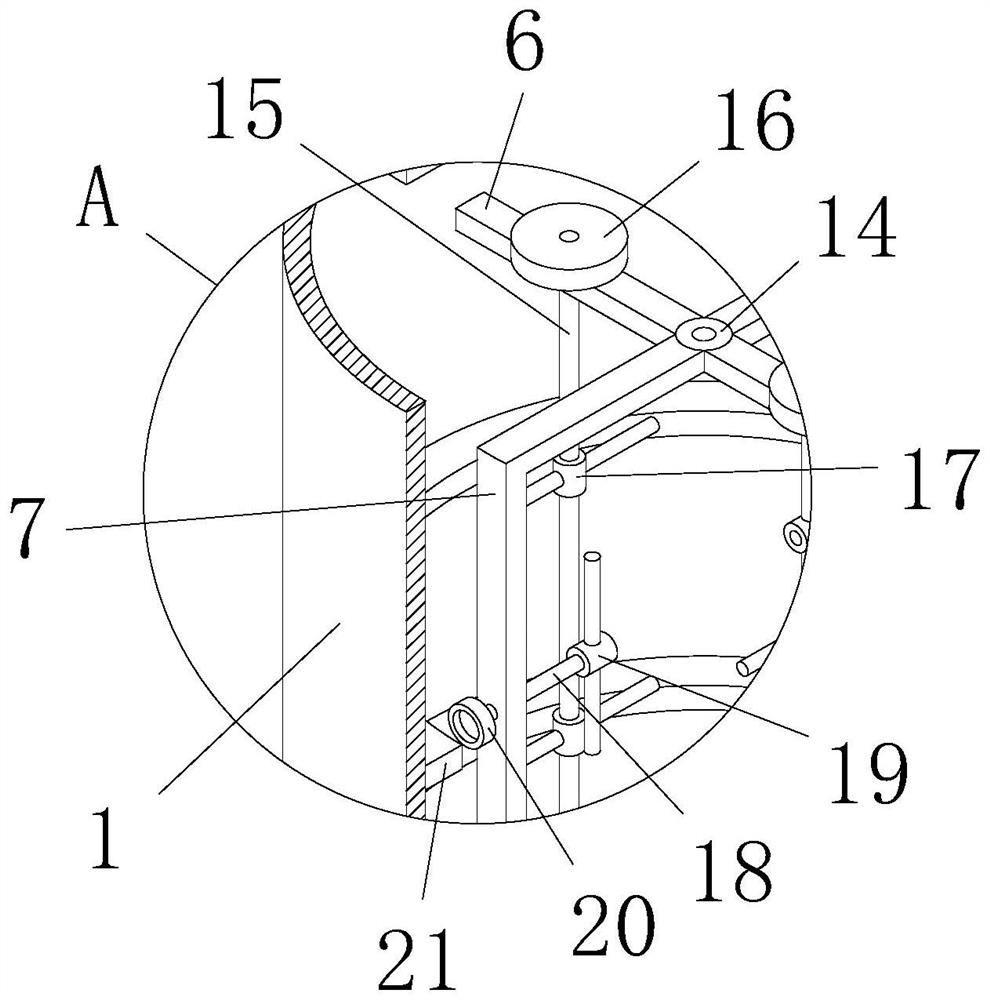

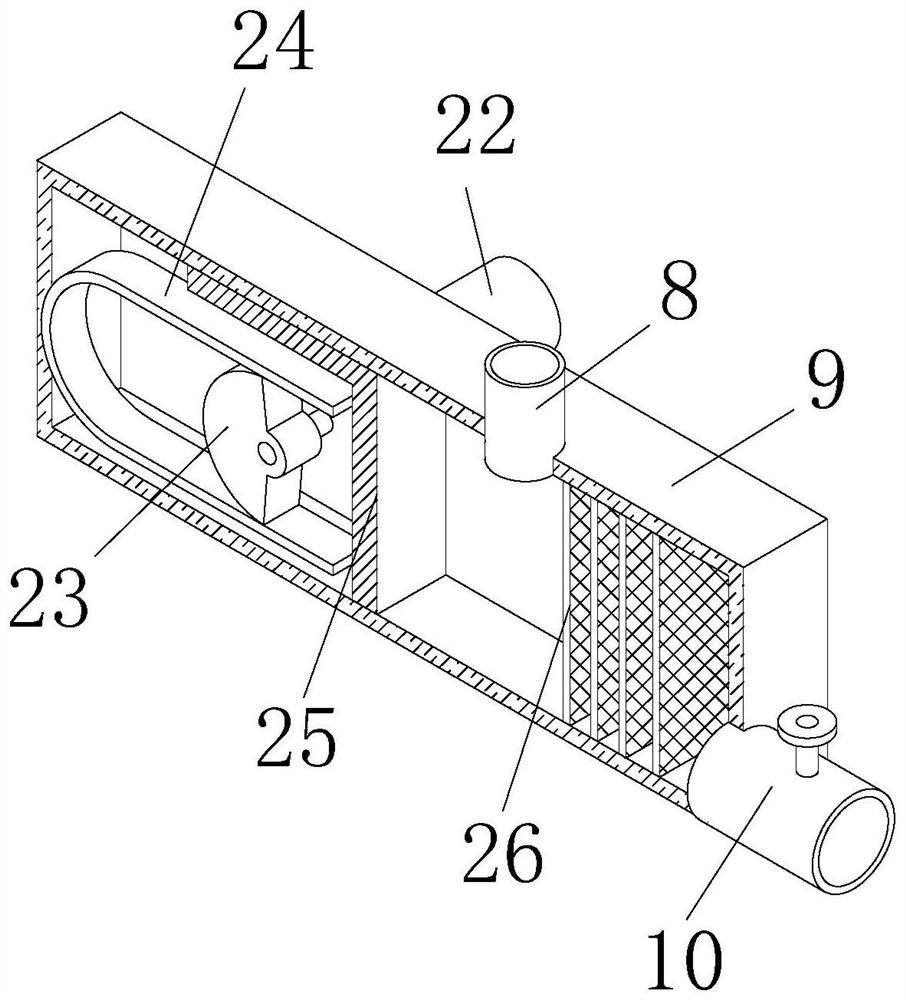

Impulse-type grouting apparatus with variable voltage variable frequency

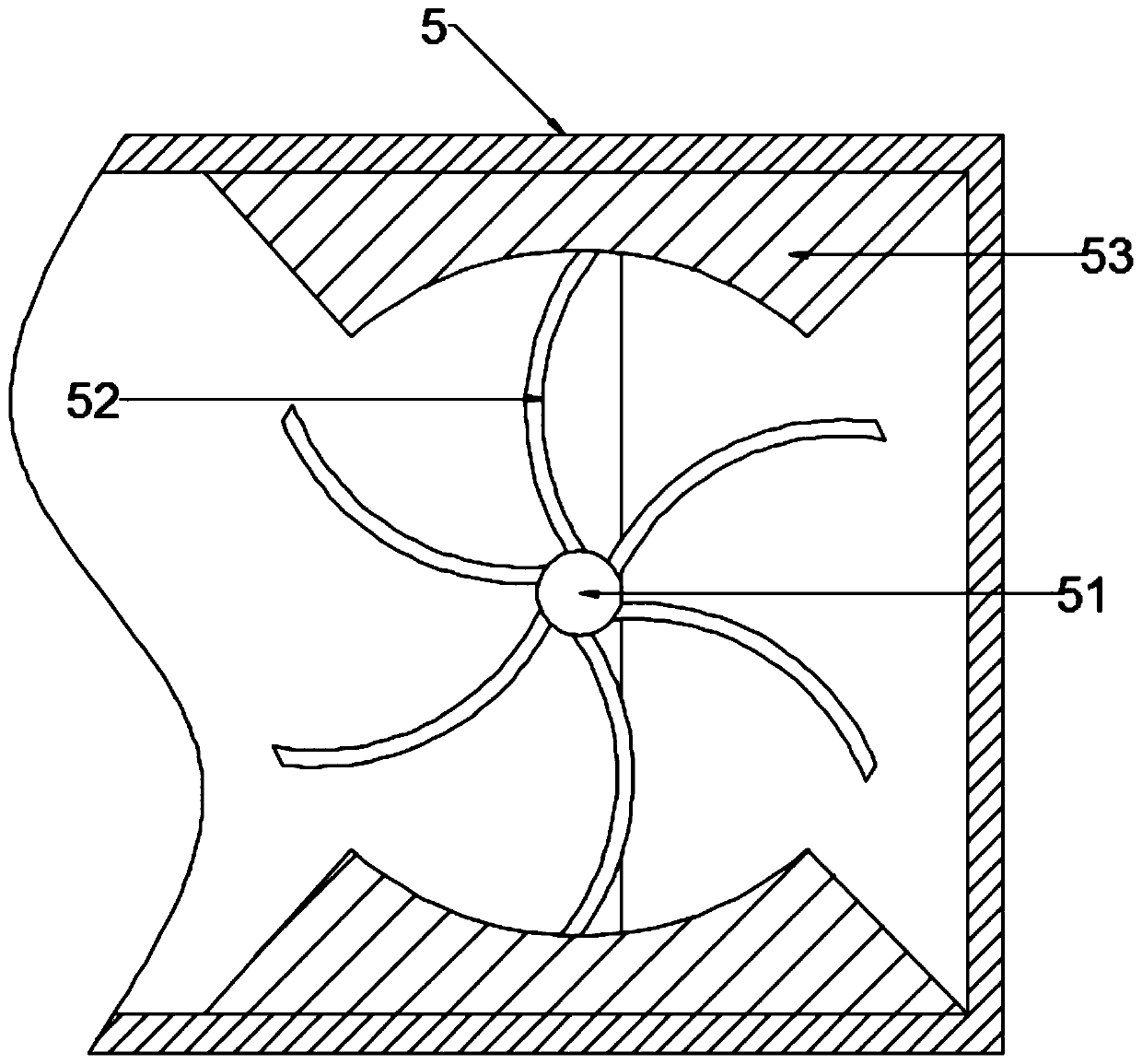

ActiveCN110542751ASpeed up emissionsAvoid being unable to dischargeEarth material testingElectric machineAir blower

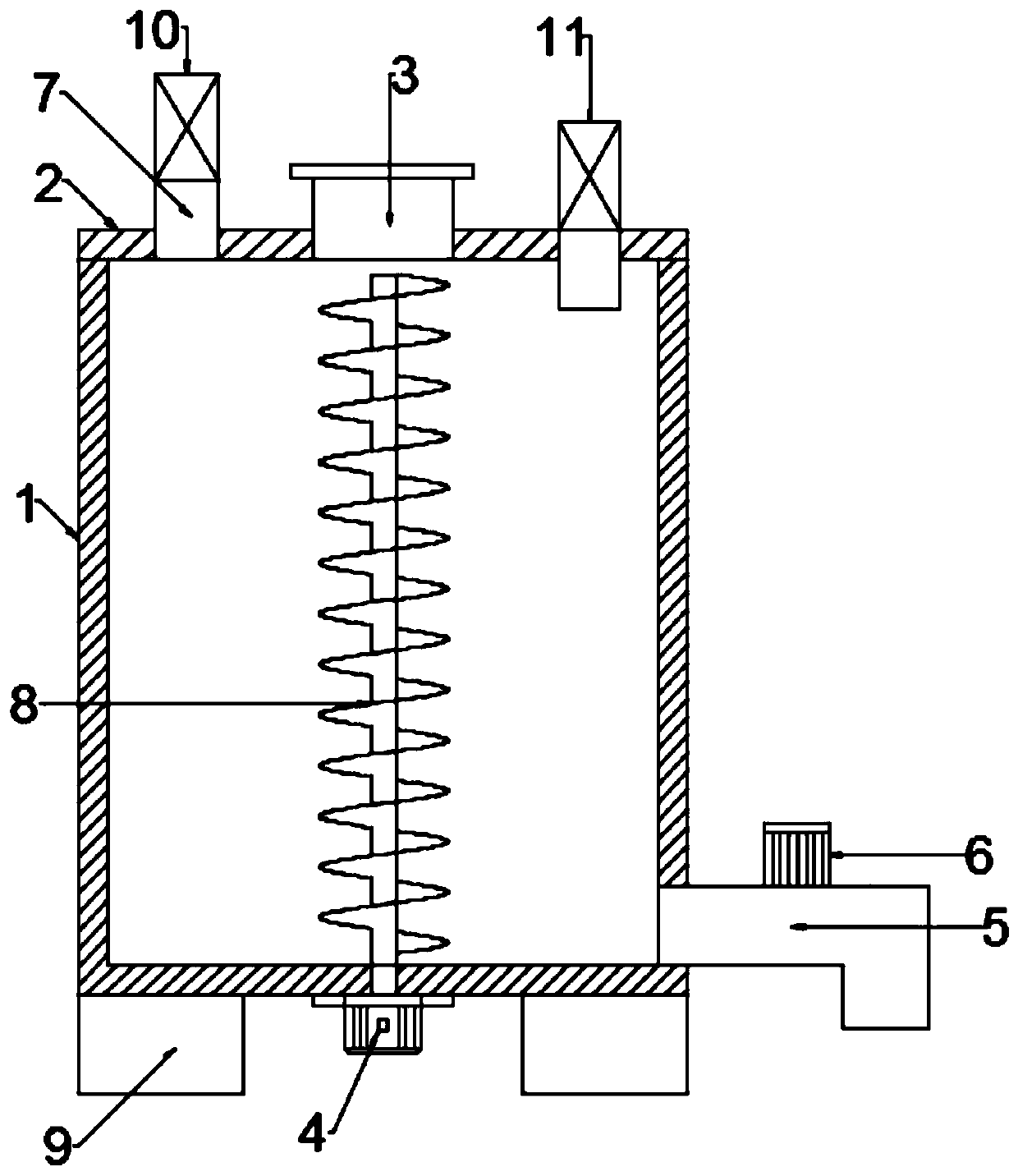

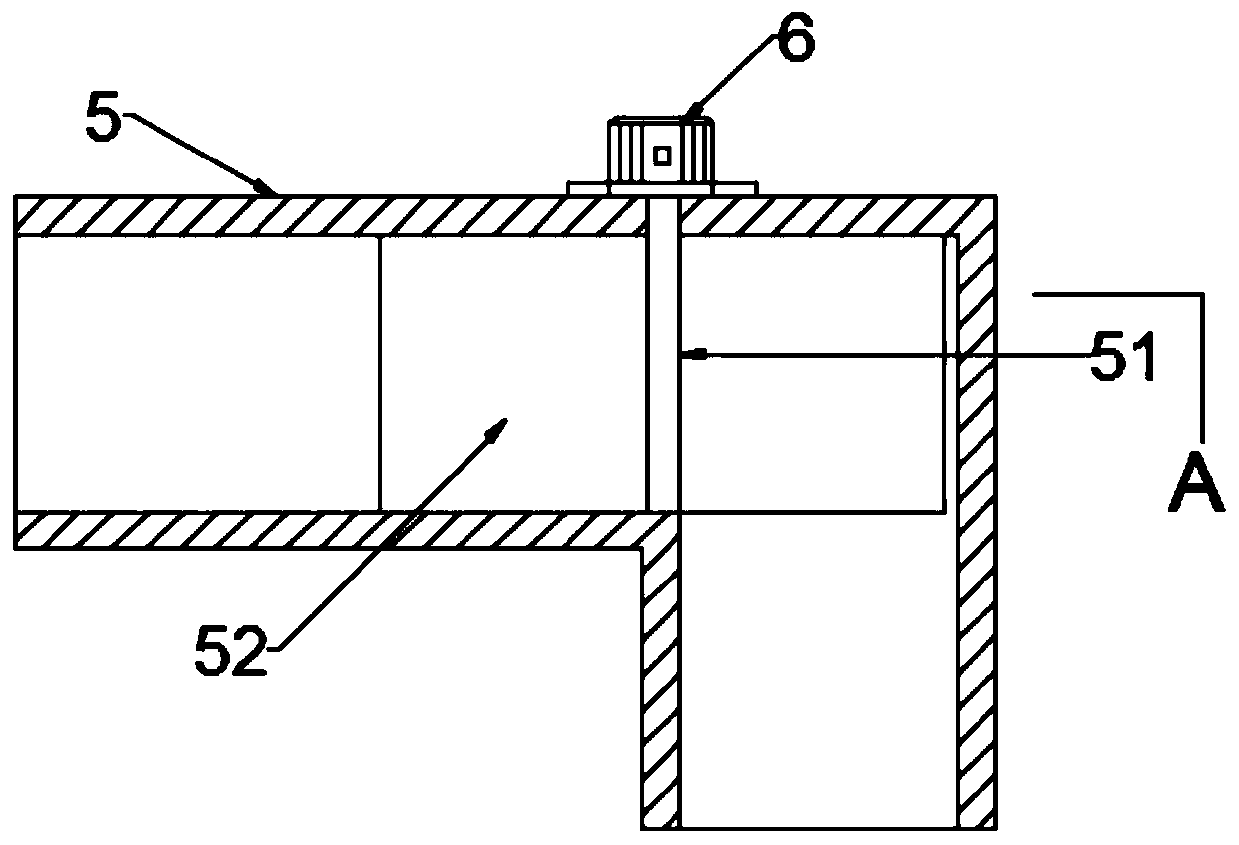

The present invention discloses an impulse-type grouting apparatus with variable voltage variable frequency. The apparatus comprises a barrel. An upper cover is movably assembled on the barrel in a riveting manner, and an inlet pipe is disposed on the upper cover in a through connection manner. A lower end of one side of the barrel is further communicated with a grouting pipe. Two groups of pressure control valves that are used for limiting flow directions and adjusting pressures are further disposed and connected on the upper cover. Both the two groups of pressure control valves are communicated with inside and outside of the barrel. Further, upper ends of the two groups of pressure control valves are respectively communicated with a suction fan and an air blower. A homogeneous structureused for stirring is further disposed and connected inside the barrel. A valve structure that controls a flow speed through rotation is further disposed inside the grouting pipe, and the valve structure drives operation by using a second motor connected on the grouting pipe. According to the impulse-type grouting apparatus, a driving speed of the second motor can be adjusted to control a sizing agent discharging speed, and the sizing agent discharging speed can also be controlled by starting the suction fan or the air blower. Materials can be discharged under cooperation, and an impulse-type grouting effect can be formed as required.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING) +1

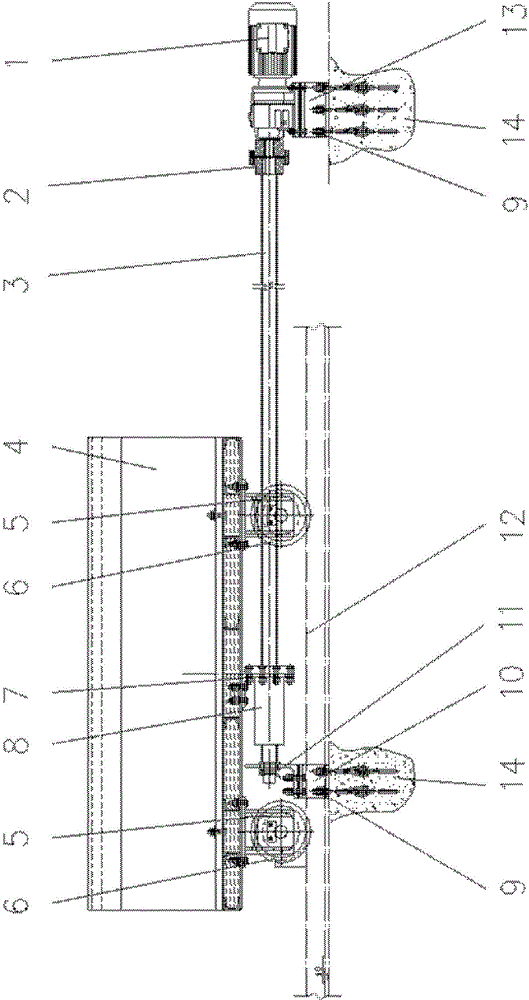

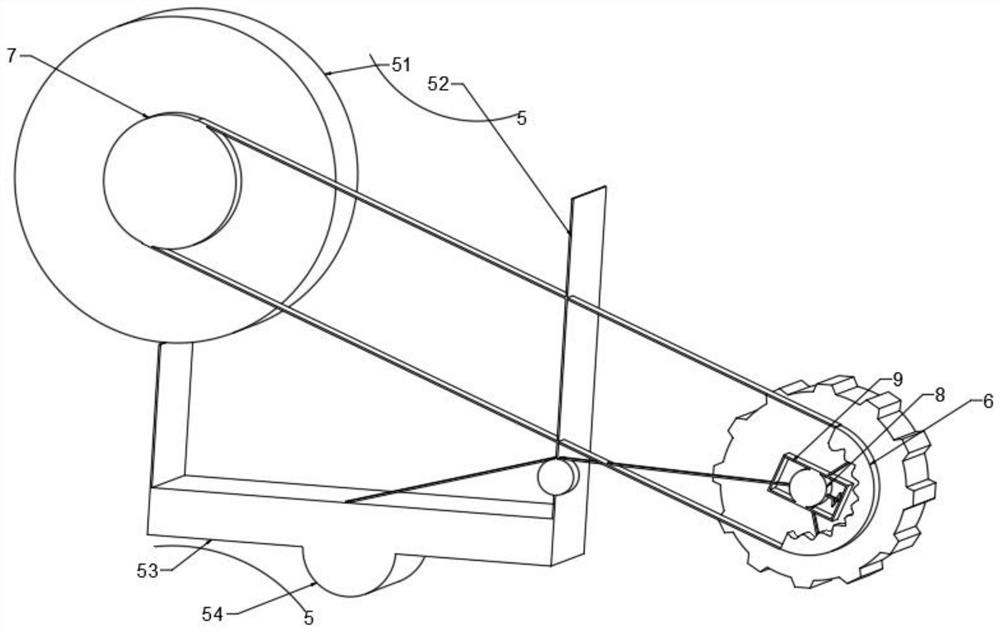

Trolley traction device

InactiveCN102721284ASolve the problem of not being able to quench and cool immediatelyAvoid being unable to dischargeCharge manipulationCouplingBall screw

The invention relates to a trolley traction device. The trolley traction device is characterized by comprising a motor, a coupler, a ball screw, a supporting bracket, a ball screw pair, a foundation bolt, a fixed base, a strut and a motor supporting seat; the fixed base is fixed on foundation in the middle of two parallel steel rails through the foundation bolt, and the strut is fixed on the fixed base; the motor supporting seat is fixed on the foundation through the foundation bolt, and the motor is fixed on the motor supporting seat; the ball screw pair is screwed onto the ball screw, the right end of the ball screw is connected with an output shaft of the motor through the coupler, the left end of the ball screw is arranged on the strut, and the ball screw is parallel to the steel rails; and the ball screw pair is fixedly connected with the bottom of a trolley frame through the supporting bracket. The trolley traction device is simple in structure, convenient to construct, install and repair, less in the manufacturing and construction cost, and high in transmission precision and transmission efficiency.

Owner:WISDRI WUHAN WIS IND FURNACE

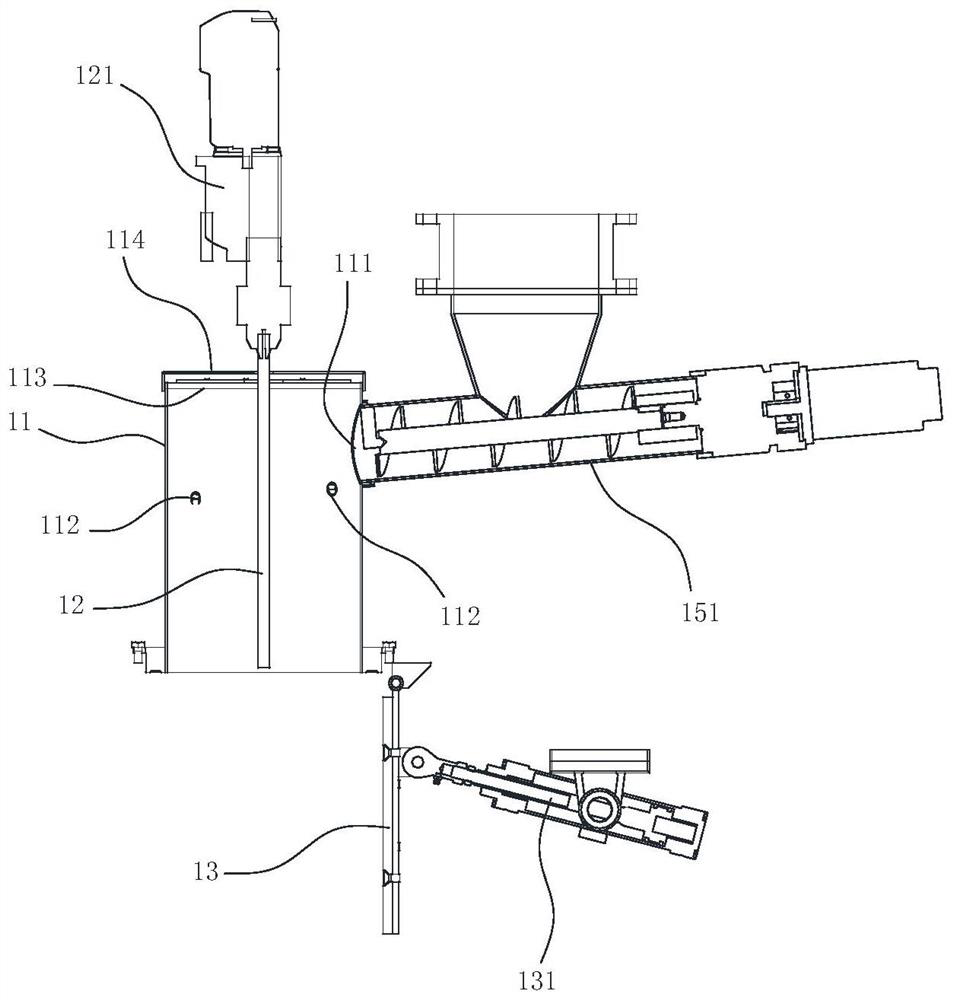

Poultry feeding apparatus based on PLC control

The invention discloses a poultry feeding apparatus based on PLC control. The apparatus comprises a clean water feeding mechanism and a feed feeding mechanism, wherein the feed feeding mechanism is located on the left side of the clean water feeding mechanism, the clean water feeding mechanism comprises a clean water feeding tank, the rear side of the top of the clean water feeding tank is fixedlyconnected with a vertical plate, the top of the front of the vertical plate is provide with a water tank, the top of the water tank is provide with a water adding port, the bottom of the water tank is fixedly connected with a water adding pipe communicating with the water tank, the bottom end of the water adding pipe penetrates the clean water feeding tank and extends to the inside of the clean water feeding tank, and the feed feeding mechanism comprises a feed feeding tank. The poultry feeding apparatus based on PLC control has a reasonable structure design, is convenient to use, can realizeautomatic feed addition, ensures the uniformity of feed in the feed tank after addition, avoids poultry food-snatching caused by stacked feed somewhere, ensures the normal growth of poultry, and meets all-round use needs.

Owner:XIAN ZHIYUEDA SOFTWARE CO LTD

Efficient catalytic cracking device for petrochemical industry production

PendingCN112812814AImprove discharge efficiencyAvoid loopsCatalytic crackingDispersed particle filtrationPtru catalystAir filter

The invention discloses an efficient catalytic cracking device for petrochemical production, and relates to the technical field of petroleum catalytic cracking; the efficient catalytic cracking device comprises a catalytic cracking device, wherein the right side of the catalytic cracking device is fixedly provided with a side support, the top of the side support is fixedly provided with a waste gas treatment device, and four corners of the bottom of the catalytic cracking device are fixedly provided with supporting legs. Through ingenious design and combination of the hollow conveying ring, the main spraying agent head and the auxiliary spraying agent head, when crude oil is catalyzed, a booster pump on the top of a catalyst tank is used for pressurizing to convey an internal catalyst to the hollow conveying ring, and then the catalyst is conveyed to the main spraying agent head and the auxiliary spraying agent head at the bottoms of a stirring shaft and a stirring paddle through the hollow conveying ring; besides, by adopting the combined arrangement of the air filter element and the exhaust fan, waste gas can be conveyed to the air filter element in the waste gas treatment device through a pipeline connected to the top of the catalytic cracking device for comprehensive multi-layer filtration, wherein the exhaust fan plays a role in accelerating filtration in the process.

Owner:刘小丽

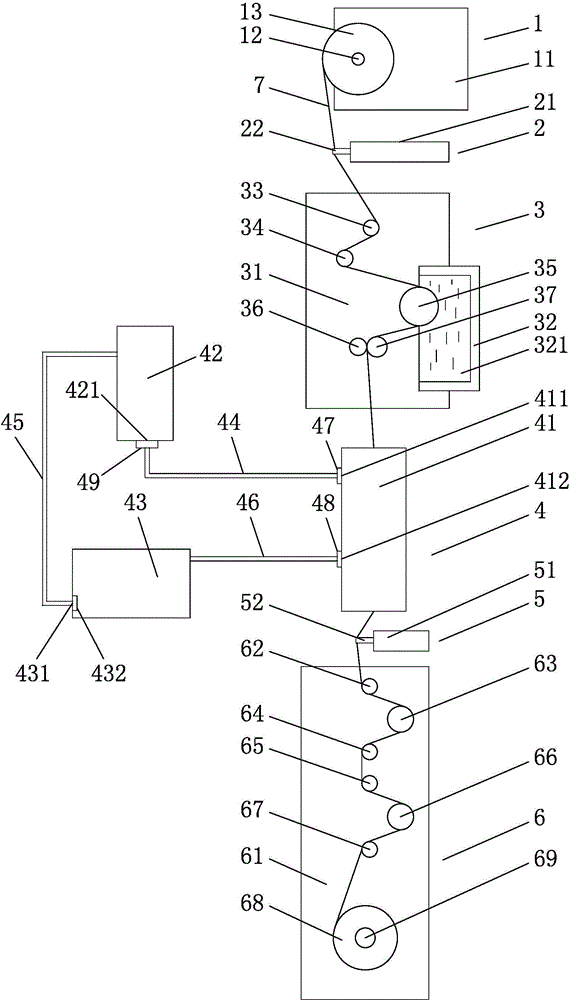

Yarn sizing device capable of recycling steam

InactiveCN104088104AAchieve recyclingAffect normal workSucessive textile treatmentsTextile treatment machine arrangementsSizingYarn

The invention relates to a yarn sizing device capable of recycling steam, and belongs to the field of spinning equipment. To solve the problems, the invention provides the following technical scheme: the yarn sizing device capable of recycling steam comprises a feeding device, a sizing device, a drying device and a yarn collecting device which are arranged in sequence, wherein the drying device comprises a steam box, a liquid recycling tank and a steam boiler; a first steam tube is arranged between the steam box and the liquid recycling tank; a second steam tube is arranged between the liquid recycling tank and the steam boiler; a third steam tube is arranged between the steam boiler and the steam box; a pressure reduction valve is arranged at a steam outlet in the steam boiler.

Owner:CHANGXING ZHIHENG CLOTHING MATERIAL

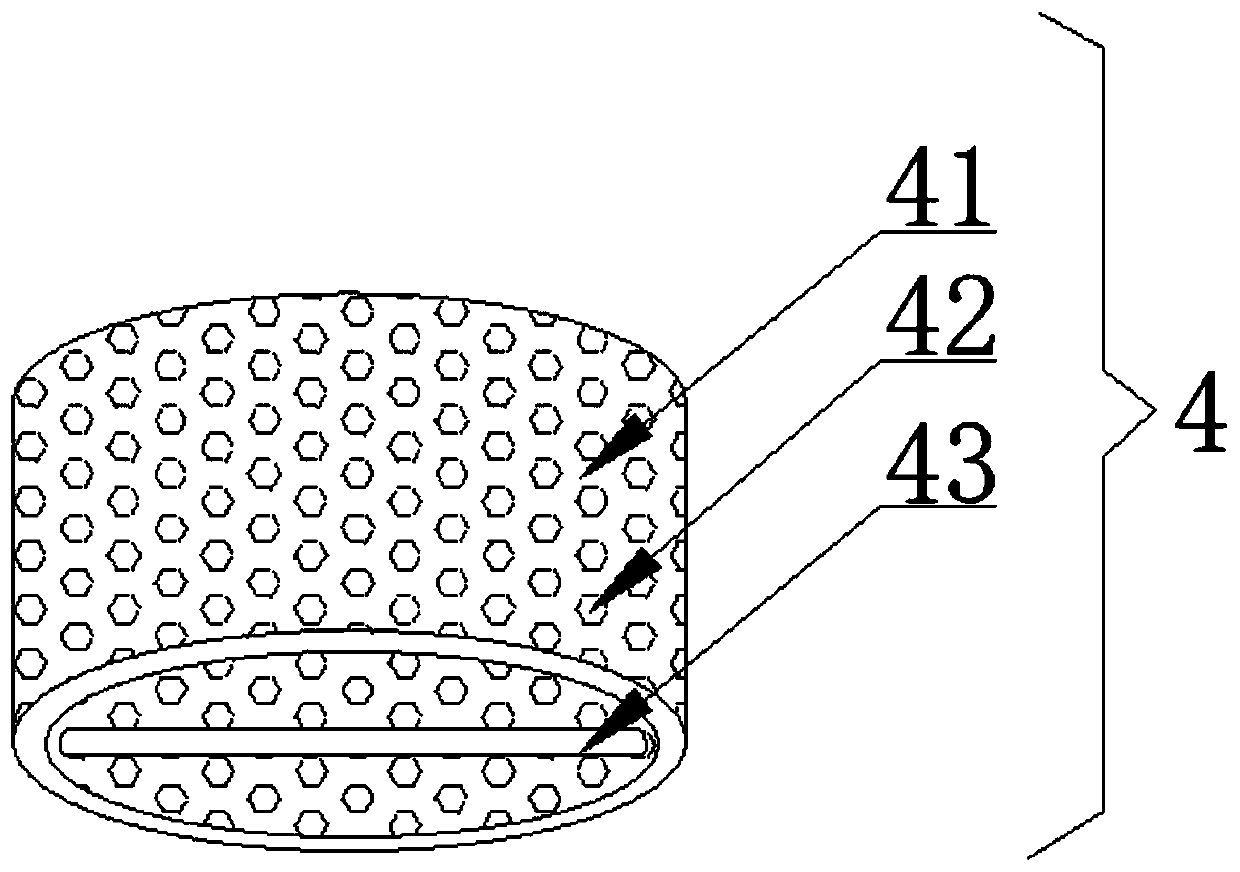

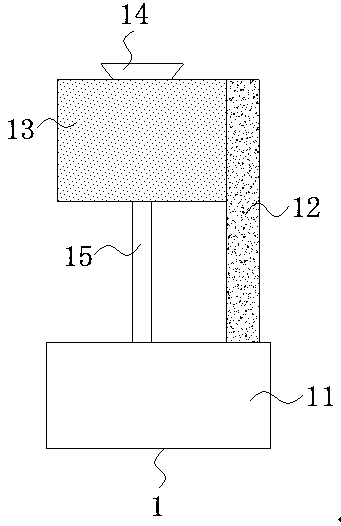

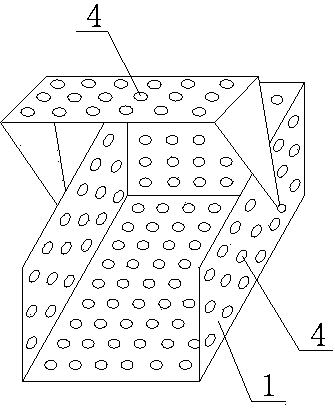

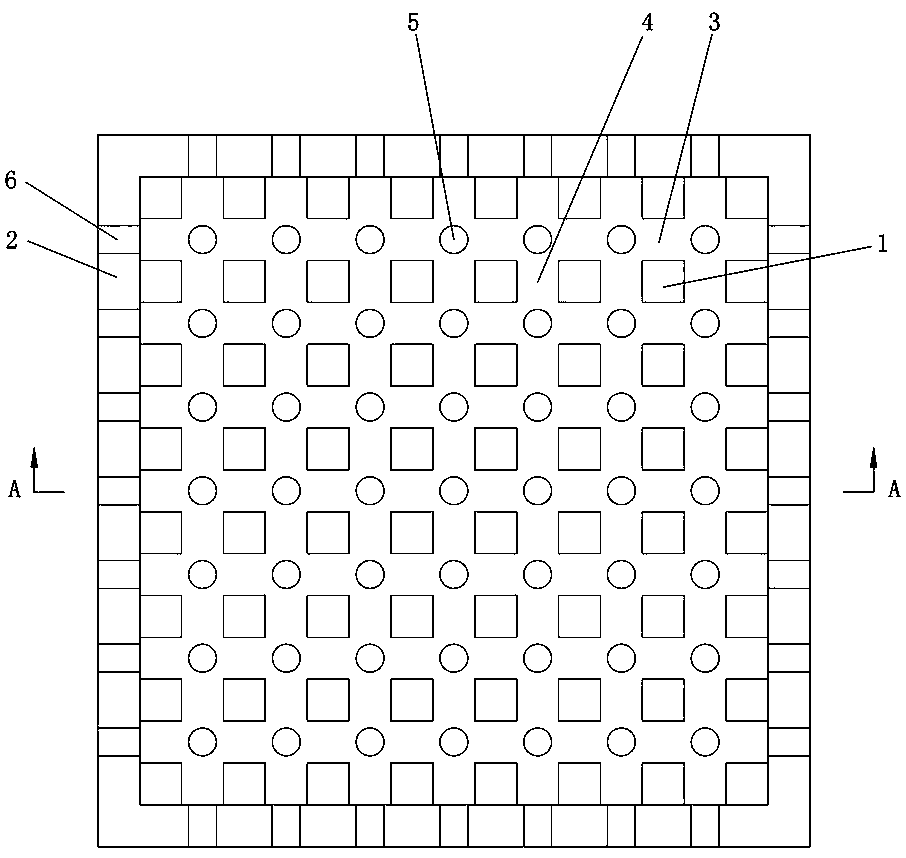

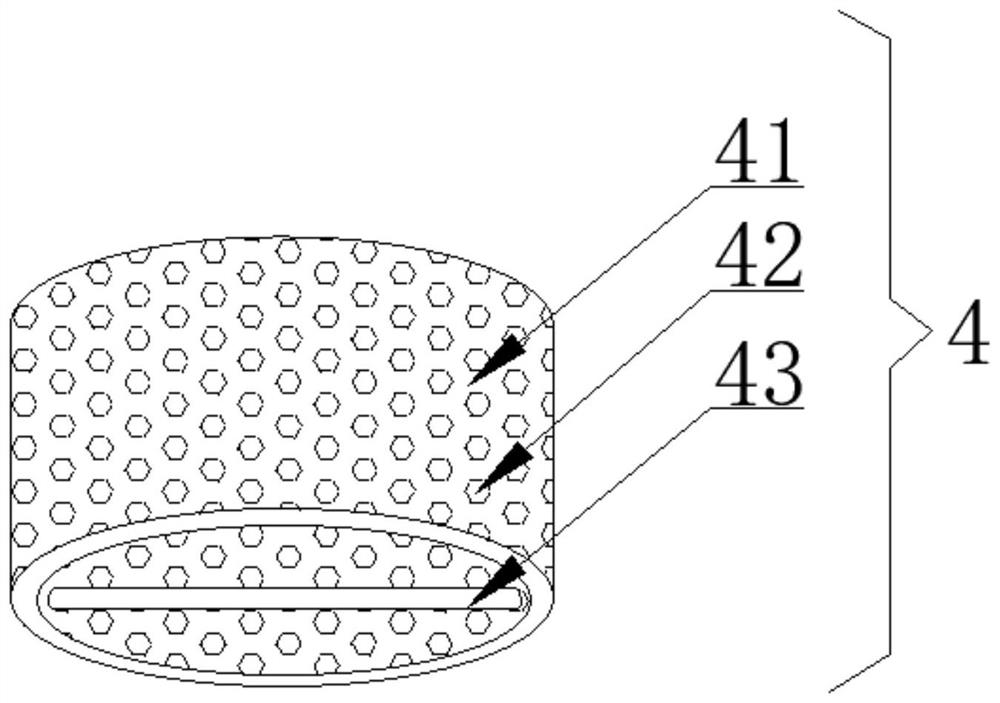

Box provided with a plurality of through holes and used for loading medicine bottles

InactiveCN103418007AAchieve loadingImprove work efficiencyLavatory sanitoryDisinfectionEngineeringDrug packaging

The invention discloses a box provided with a plurality of through holes and used for loading medicine bottles. The box provided with the plurality of through holes and used for loading the medicine bottles comprises a box body (1), wherein the box body (1) is a rectangle tank body lacking a side face, the box body (1) is provided with a moving blocking plate which comprises a base plate (2) and side plates (3) respectively fixedly disposed at two ends of the base plate (2), the two side plates (3) are respectively fixedly disposed on two parallel side faces of the box body (1), and the bottom and the side of the box body (1) are all provided with the through holes (4). Due to the structure, the box provided with the plurality of through holes and used for loading the medicine bottles is simple in structure and favorable for sterilization. Meanwhile, the medicine bottles are taken out from the box conveniently, and work efficiency is improved.

Owner:CHINA CHENGDU ANIMAL HUSBANDRY IND BIOPHARM

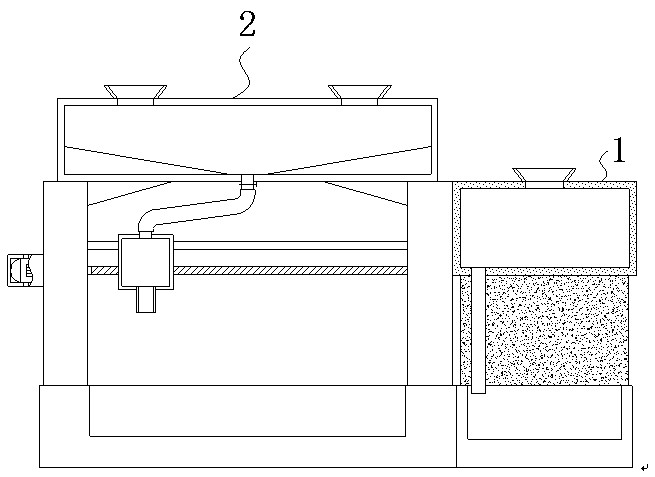

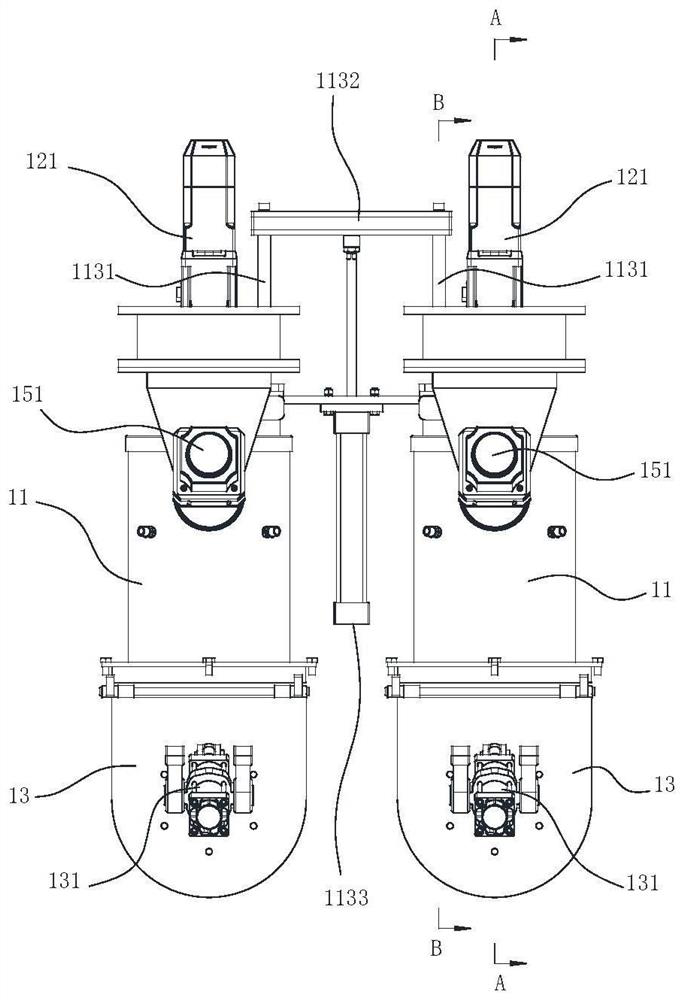

Stirring device and heat preservation and sound insulation board pouring system

ActiveCN113733350AReduce wall hangingReduce feeding inaccuracyDischarging apparatusMixing operation control apparatusProcess engineeringHeat conservation

The invention belongs to the technical field of heat preservation and sound insulation board production and processing, and particularly relates to a stirring device and a heat preservation and sound insulation board pouring system. The stirring device comprises a stirring barrel, stirring blades and a valve, and a feeding port and a nozzle are formed in the barrel wall; and the feeding port and the nozzle are arranged at the upper half part of the barrel wall. The bottom of the stirring barrel is not provided with a closed-up material collecting structure, and the stirring barrel is of a straight-through structure in the whole vertical direction so that the wall hanging phenomenon of materials can be effectively reduced; the materials are directly released into a mold after being mixed into slurry and do not pass through a redundant conveying device any more, and the phenomenon of inaccurate feeding caused by material solidification is reduced to the maximum extent; and the stirring barrel has a self-cleaning function, turbid liquid generated by cleaning does not need to be discharged and is directly used as a solvent for next stirring, high-frequency cleaning of equipment is realized in the whole processing process, waste liquid is not generated, and the production process is more environment-friendly.

Owner:山东威宝节能科技集团有限公司 +1

A kind of boat and boat assembly used for cemented carbide dewaxing process

The invention discloses a boat and boat group for a hard alloy dewaxing process. The boat for the hard alloy dewaxing process comprises a bottom plate and a side wall; the side wall is enclosed at the outer edge of the obverse side of the bottom plate; more than one horizontal flow guide slot and more than one longitudinal flow guide slot are formed in the obverse side of the bottom plate; the horizontal flow guide slots are intersected with the longitudinal flow guide slots, and bottom plate through holes are formed in the bottom plate at the intersections; and more than one side wall through hole is formed in the side wall. The boat group comprises a cover plate and more than two groups of boats for the hard alloy dewaxing process, the boats are vertically stacked, and the cover plate covers the side wall of the boat located at the topmost layer. The boat and boat group for the hard alloy dewaxing process, disclosed by the invention, have the advantages of high dewaxing efficiency, stable product quality and the like.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

Residual water removing device and dish washing machine

PendingCN111973125AGood removal effectWon't clogTableware washing/rinsing machine detailsEnvironmental engineeringHome appliance

The invention relates to the technical field of household appliances, in particular to a residual water removing device and a dish washing machine. The residual water removing device comprises a bodyand a negative pressure structure, and a cavity is formed in the body; at least part of the negative pressure structure is arranged in the cavity; the negative pressure structure is arranged in the cavity and divides the cavity into a water absorption cavity, a circulation opening is formed in the water absorption cavity, and the water absorption cavity has the water absorption state that the volume is increased to form negative pressure and water is absorbed through the circulation opening and the water drainage state that the volume is reduced and water is drained through the circulation opening under the action of the negative pressure structure. The residual water removing device is not blocked, and the residual water removing effect is good.

Owner:GREE ELECTRIC APPLIANCES INC

A pulse type grouting device with variable frequency and variable pressure

ActiveCN110542751BSpeed up emissionsAvoid being unable to dischargeEarth material testingElectric machineryEngineering

The present invention discloses an impulse-type grouting apparatus with variable voltage variable frequency. The apparatus comprises a barrel. An upper cover is movably assembled on the barrel in a riveting manner, and an inlet pipe is disposed on the upper cover in a through connection manner. A lower end of one side of the barrel is further communicated with a grouting pipe. Two groups of pressure control valves that are used for limiting flow directions and adjusting pressures are further disposed and connected on the upper cover. Both the two groups of pressure control valves are communicated with inside and outside of the barrel. Further, upper ends of the two groups of pressure control valves are respectively communicated with a suction fan and an air blower. A homogeneous structureused for stirring is further disposed and connected inside the barrel. A valve structure that controls a flow speed through rotation is further disposed inside the grouting pipe, and the valve structure drives operation by using a second motor connected on the grouting pipe. According to the impulse-type grouting apparatus, a driving speed of the second motor can be adjusted to control a sizing agent discharging speed, and the sizing agent discharging speed can also be controlled by starting the suction fan or the air blower. Materials can be discharged under cooperation, and an impulse-type grouting effect can be formed as required.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING) +1

Efficient alga salvaging device based on lake treatment

The invention discloses an efficient alga salvaging device based on lake treatment. The efficient alga salvaging device comprises a shell, a storage battery is arranged inside the shell, a motor is fixed to the left side of the shell, a fan is connected to the right side of the motor through a bearing, a gear disc is connected to the right side of the motor through a bearing, a bevel gear is connected to the lower portion of the gear disc through a gear, a salvaging assembly is arranged on the right side of the shell and connected to a bevel gear crawler belt, the salvaging assembly comprises a separation wheel, a separation bin is fixed to the right side of the separation wheel and fixedly connected to the left side of the shell, a filter screen is slidably connected to the lower portion of the interior of the separation bin, an elastic rod is fixed to the middle of the filter screen, an elastic ring is fixed to the rear side of the bevel gear, a conveying wheel is fixed to the middle of the separation wheel, and the elastic ring is connected to a conveying wheel crawler belt. The efficient alga salvaging device based on the lake treatment has the characteristics of controlling the salvaging speed and accelerating alga fermentation by judging the amount of algae.

Owner:陈景峰

An integrated drainage assembly and washing machine

ActiveCN104294546BCompact structureSimplify the installation processOther washing machinesTextiles and paperFailure rateEngineering

The invention relates to an integrated drainage component and a washing machine. The integrated drainage component comprises a drainage valve and a drainage motor, the drainage valve comprises a valve body and a valve cover, the drainage motor comprises a waterproof box, a drainage motor body is arranged in the waterproof box, the valve cover and the waterproof box are integrated, the drainage motor is detachably connected with the valve body through the valve cover, and an emergency drain outlet is further formed in a filter cavity. The drainage valve, the drainage motor, a filter and an emergency drainage pipeline are integrated, the structure is compact, installation is simple, cost is lowered, drainage noise is lowered, and the failure rate is lowered.

Owner:QINGDAO HAIER DRUM WASHING MACHINE

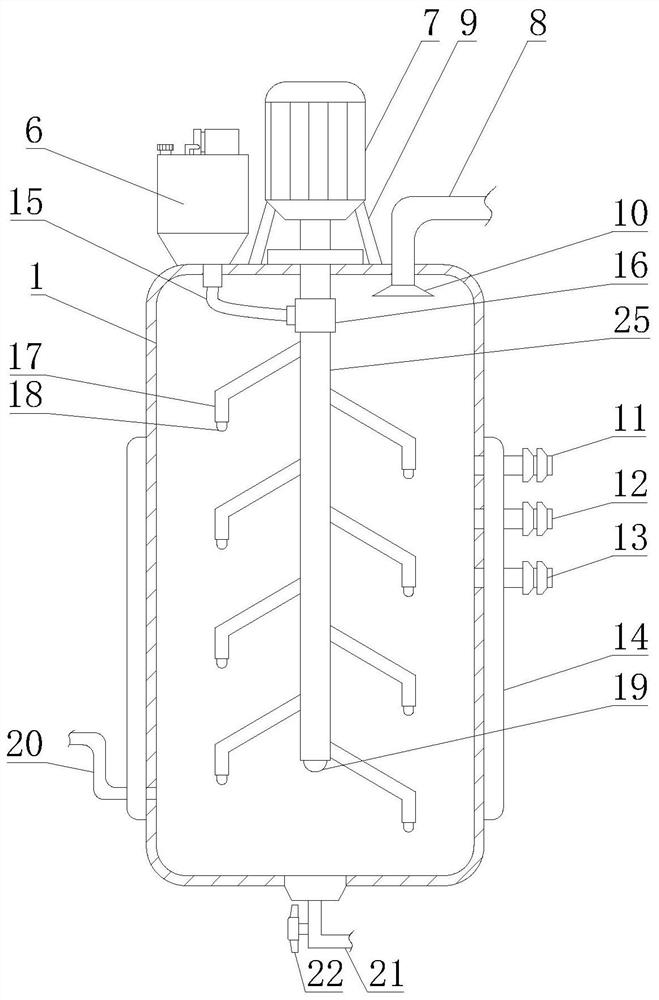

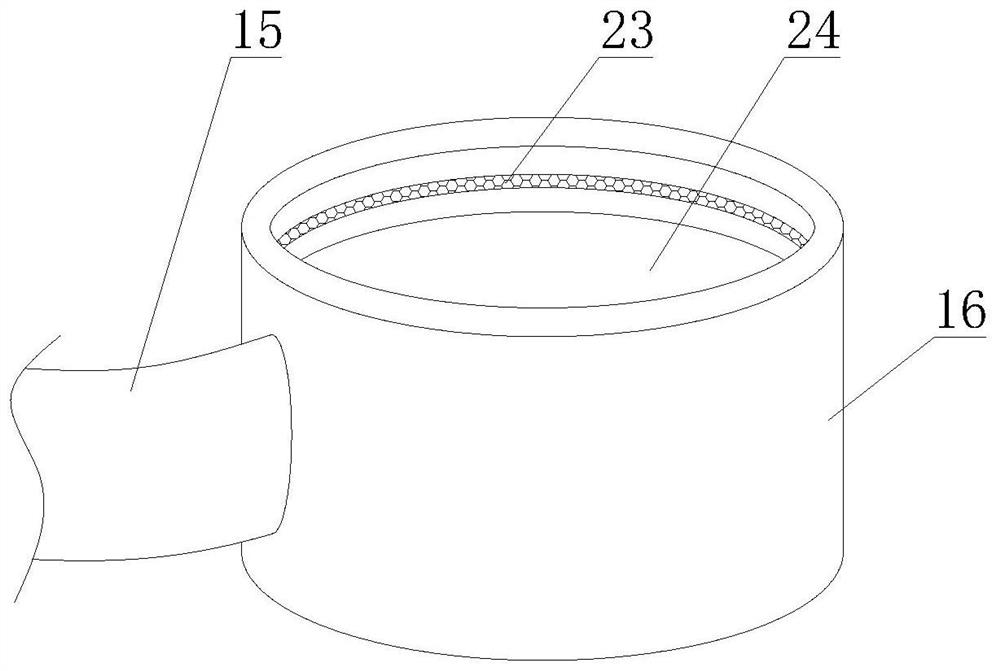

High-concentration formaldehyde-free environment-friendly color fixing agent production filtering equipment

PendingCN113828208AImprove filter press discharge efficiencyImprove production and processing efficiencyRotary stirring mixersMixer accessoriesProcess engineeringFilter press

The invention relates to the technical field of color fixing agents, and discloses high-concentration formaldehyde-free environment-friendly color fixing agent production filtering equipment which comprises a stirring kettle body, four supporting legs are arranged on the bottom face of the stirring kettle body, a liquid inlet pipe fixedly sleeves the right outer wall of the top end of the stirring kettle body, and a feeding pipe fixedly sleeves the rear end of the top face of the stirring kettle body. The inner side wall of the bottom end of the stirring kettle body is fixedly sleeved with a partition plate, a stirring cavity of the stirring kettle body is formed on the partition plate, a heating cavity of the stirring kettle body is formed below the partition plate, a first stirring supporting rod and a second stirring supporting rod are arranged in the stirring cavity of the stirring kettle body, and a heating plate is arranged in the heating cavity of the stirring kettle body. The left outer wall and the right outer wall of the bottom end of the stirring kettle body are fixedly sleeved with one-way valve pipes A respectively, the other end of each of the two one-way valve pipes A is fixedly sleeved with a filter pressing box body, and by effectively improving the stirring effect and the stirring efficiency and improving the extruding, filtering and discharging efficiency, the production and processing efficiency of the high-concentration formaldehyde-free color fixing agent is effectively improved.

Owner:浙江新海天生物科技有限公司

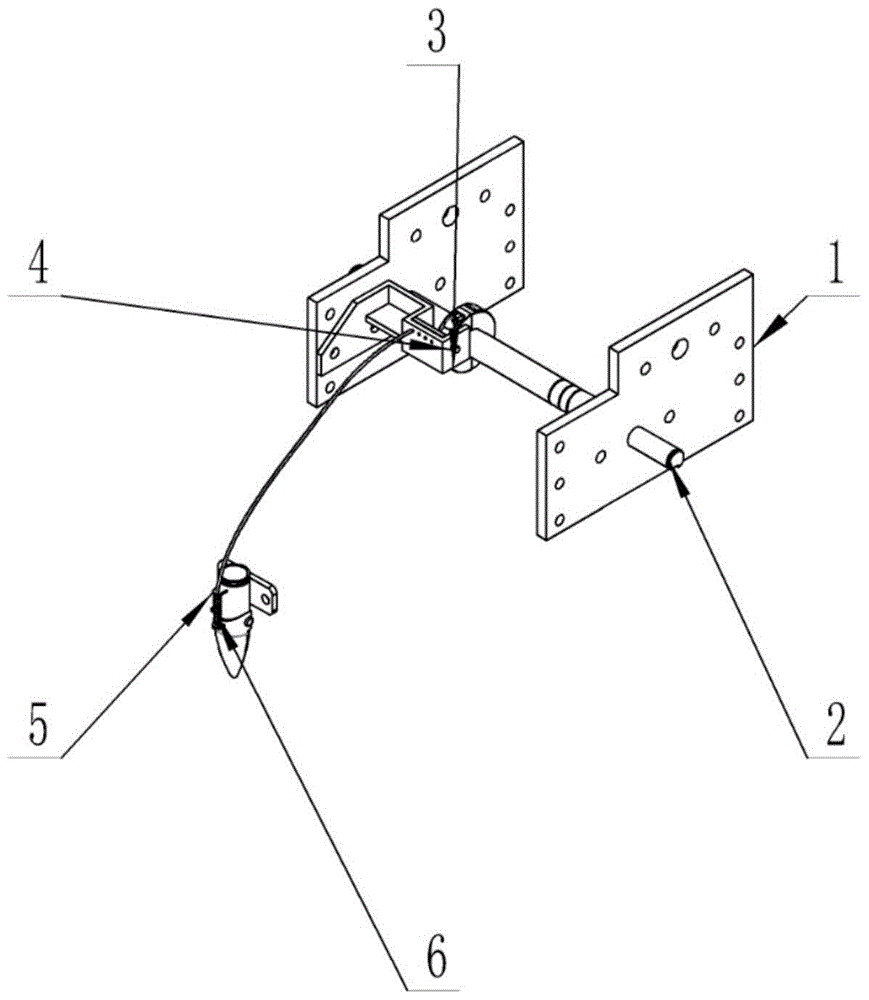

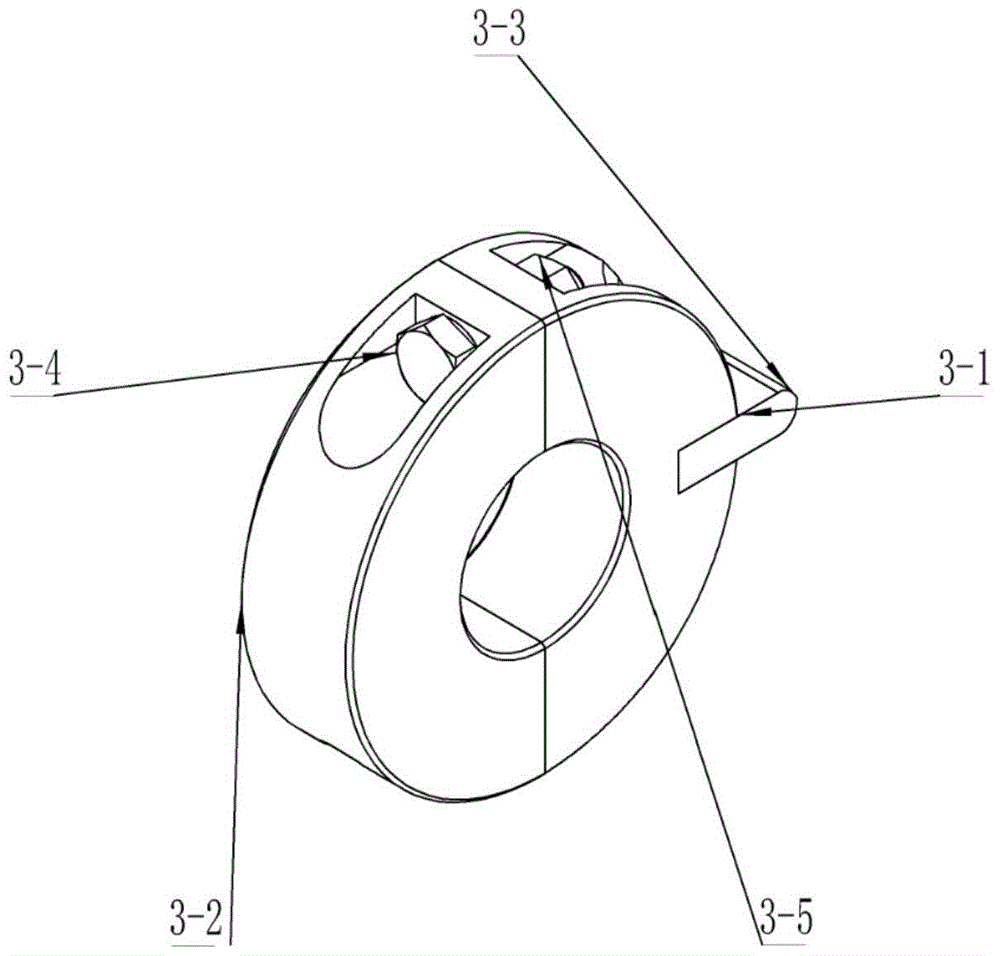

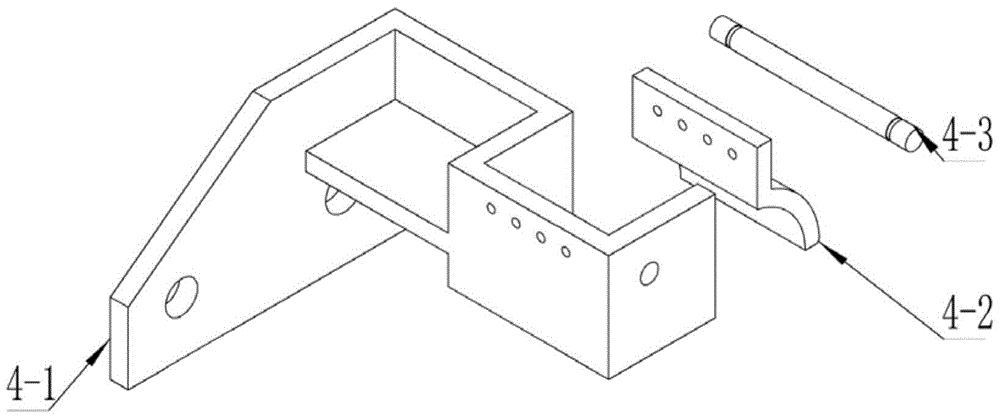

Corn in-line duckbill forced discharge device

The invention relates to the technical field of a corn seeding machine, specifically to a direct-insertion type duckbill forced seed discharging device for corn. The device is characterized by comprising an installation top plate fixedly connected with a frame of a seeding machine, wherein the installation top plate is provided with a camshaft which is provided with a cam assembly; and a pulling sheet assembly is arranged on the plate surface of the installation top plate at a position corresponding to the cam assembly and is connected with a duckbill assembly via pulling wires. According to the invention, the device can utilize instant dynamic load to shake off soil adhered on the duckbill assembly which is taken out from soil, so the precise corn seeding machine does better in controlling qualified corn plant spacing; a pulling sheet frame is used, so good strength and high precision are obtained; the pulling sheet is used to pull four pulling wires, so structure is simple, and installation is convenient; the direct-insertion type duckbill adaptable to an direct-insertion type rod is adopted, so the problems of soil entering when the duckbill assembly enters the soil and incapability of seed discharging when the duckbill assembly is taken out from the soil; and the device can be timely forced to start according to operation cycles. The device can improve production efficiency of precision corn seeding and mitigate labor intensity of farmers.

Owner:GANSU AGRI UNIV

Lotus root processing slurry dehydration device

The invention relates to the technical field of starch processing equipment, and particularly discloses a lotus root processing slurry dewatering device. The lotus root processing slurry dewatering device comprises a water collecting barrel, wherein a dewatering barrel is rotationally connected into the water collecting barrel; filter holes are formed in the side wall of the dewatering barrel; only a liquid phase runs through the filter holes; a discharge pipe is arranged on the top of the water collecting barrel; a transmission shaft is connected to the bottom of the dewatering barrel; a cavity is formed in the transmission shaft; a vertical rod is arranged inside the cavity; a piston connected with the dewatering barrel in a sliding and sealed manner is arranged on the top of the vertical rod; a curved groove is formed in the side wall of the vertical rod; a guide pin connected with the curved groove in a sliding manner is arranged on the side wall of the cavity; a feeding barrel fixed to the machine frame is arranged above the water collecting barrel; a feeding check valve is arranged at the bottom of the feeding barrel; the feeding check valve is connected with a feed pipe communicated with the dewatering barrel; a push rod is arranged on the top of the piston; the push rod runs through the feed pipe and stretches into the feeding barrel; a plurality of blades are arrangedon the push rod positioned inside the feeding barrel. Through adoption of the technical scheme, the problem that in the prior art, a machine is required to be shut down for taking out starch manuallyin the lotus root slurry dewatering process is solved.

Owner:山东果然食品有限公司

A kind of bucket of underground ore transporting car which is convenient for drainage

InactiveCN106143515BReduce moisture contentReduce weightTipping wagonsEngineeringMechanical engineering

The invention discloses an underground ore transfer car bucket promoting drainage. The underground ore transfer car bucket comprises a bucket box. An opening is formed in the side wall of one side of the bucket box. The top of the opening is connected with an opening and closing plate through a rotating rod. A fixing plate is arranged on one side of the opening and closing plate. A fixing base is arranged at the bottom of the fixing plate. The fixing base is located on the outer side of the bucket box at the bottom of the opening. The two ends of the bottom of an inner cavity of the bucket box are provided with a first inclined base and a second inclined base respectively. The first inclined base is of a hollow structure. A flow separation tube is arranged inside the first inclined base. A first filter plate is arranged on the surface of the first inclined base. A fan, the first inclined base, a hose, the flow separation tube and the first filter plate are used in a cooperation mode, ore inside the bucket box is dried, meanwhile, the water content of ore is decreased, the weight of the ore is lowered, power of a transportation headstock is saved, then, the transportation efficiency is improved, and the effect of prolonging the service life of a transfer car is achieved.

Owner:WUXI HENGDA MINE MACHINERY

Four-shaft shredding machine for waste steel

ActiveCN114602616AGood shredding effectEnhanced secondary shredding effectGrain treatmentsElectric machineryStructural engineering

The invention relates to the technical field of steel processing, and discloses a waste steel four-shaft shredding machine which comprises a rack, the middle of the rack is fixedly sleeved with a sieve plate, leaking holes are evenly formed in the sieve plate, and two symmetrical motors I are fixedly connected to the middle of one end of the rack; a motor I is fixedly connected to the base, blade wheels I which are evenly distributed are fixedly connected to an output shaft of the motor I, a hydraulic cavity is formed in the center of each blade wheel I, three movable cavities which are evenly distributed are formed in each blade wheel I, and shredding blades are movably connected into the movable cavities in a sleeved mode. Through the designed blade wheels I, blade wheels II and a sieve plate, after the two blade wheels I conduct preliminary crushing on the waste steel, the crushed waste steel can enter the meshed crushing part of the blade wheels I and the blade wheels II again under the limitation of the sieve plate and the driving of the blade wheels I and the blade wheels II, so that the waste steel is shredded multiple times, and the crushing efficiency is improved. And the shredded waste steel is discharged after reaching the qualified volume.

Owner:唐山谷润科技有限公司

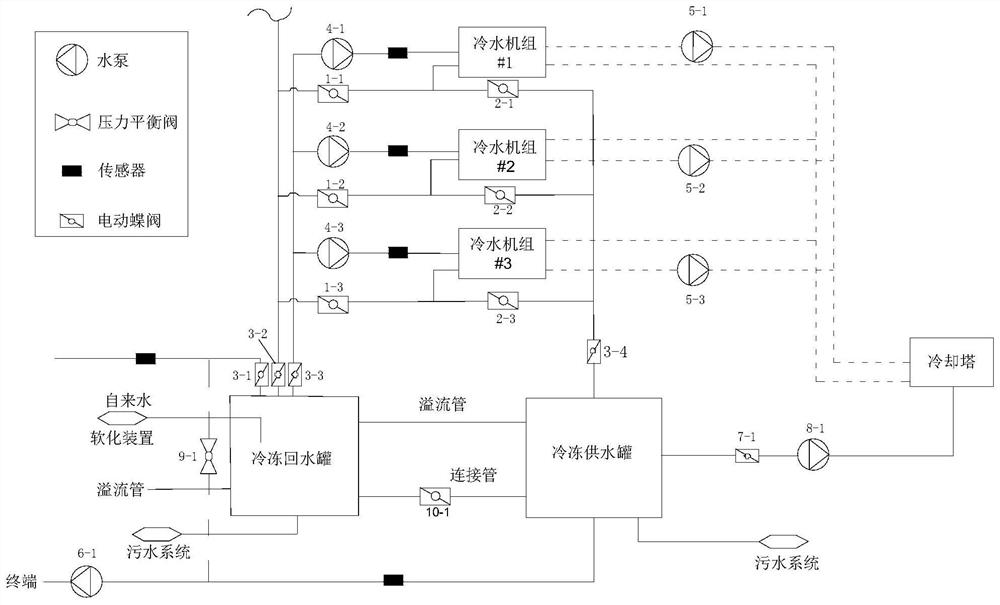

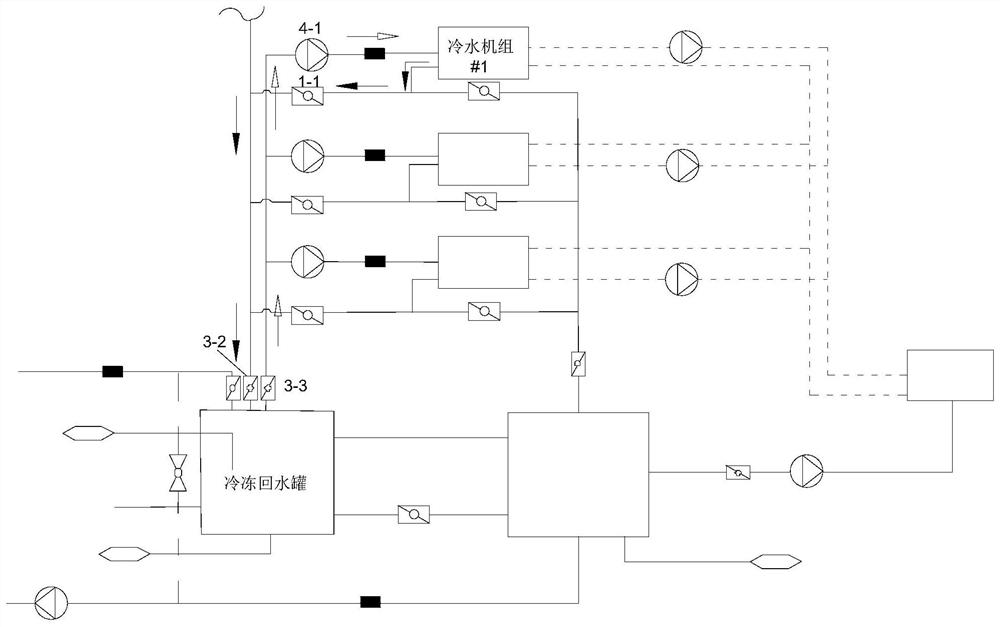

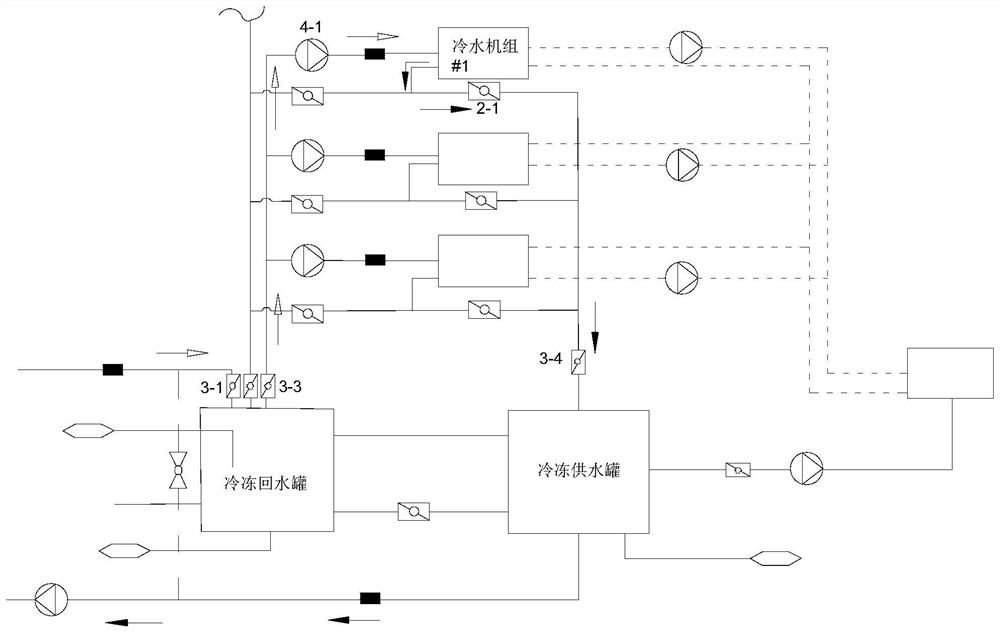

Freezing side refrigeration structure, refrigeration system and control method of refrigeration system

PendingCN113623771APlay a bufferPlay the role of cold storageMechanical apparatusLighting and heating apparatusRoom temperatureProcess engineering

The invention provides a freezing side refrigeration structure, a refrigeration system and a control method of the refrigeration system, relates to the technical field of refrigeration equipment, and solves the technical problems that when the cold load of a building changes greatly and quickly, addition and subtraction control of a refrigeration system needs reaction time, so that the system runs unstably, and the room temperature fluctuates greatly. According to the freezing side refrigeration structure, a freezing water supply tank is additionally arranged on a freezing water supply main pipeline, a freezing water return tank is additionally arranged on a freezing water return main pipeline, and by combining control of a valve assembly and a water pump assembly, the effects of low temperature and stable cold supply can be achieved by utilizing branch circulation in the starting-up process, when the cold load of the building changes greatly and quickly and and a unit cannot quickly realize addition and subtraction control reaction, the buffer and cold accumulation effects can be achieved, so that stable, efficient and low-temperature cold supply of some buildings with high control requirements is ensured, and the problems of unstable system operation, out-of-control room temperature and the like caused by the fact that factors such as flow and water temperature cannot be quickly controlled during addition and subtraction control of a conventional air conditioning system unit are solved.

Owner:GREE ELECTRIC APPLIANCES INC

Filtration device for oil production well hot washing liquid

ActiveCN110772858BImprove filtering effectQuick clean upStationary filtering element filtersHelical bladeEngineering

Owner:孙雨飞

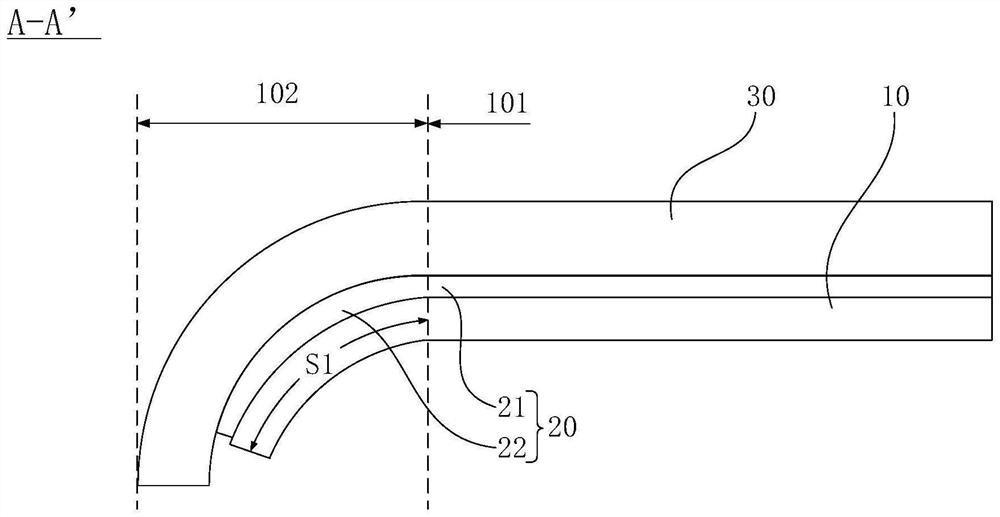

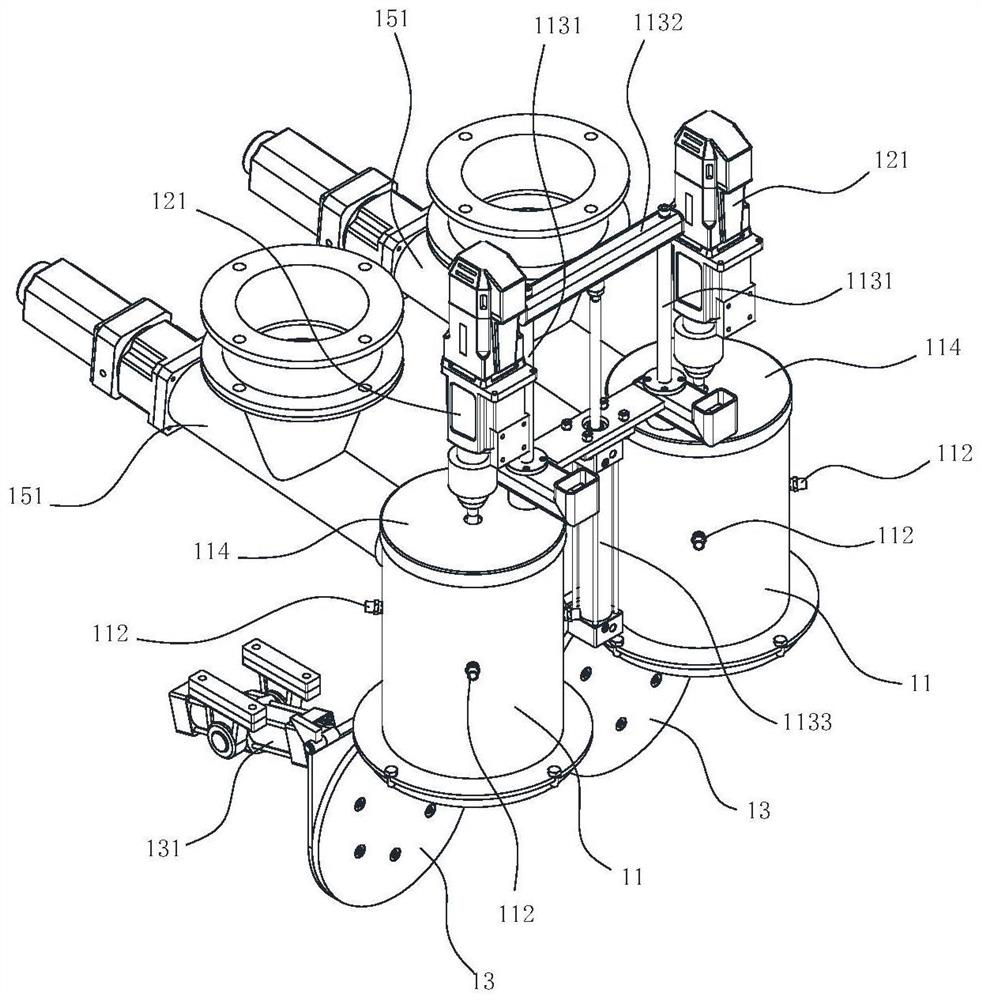

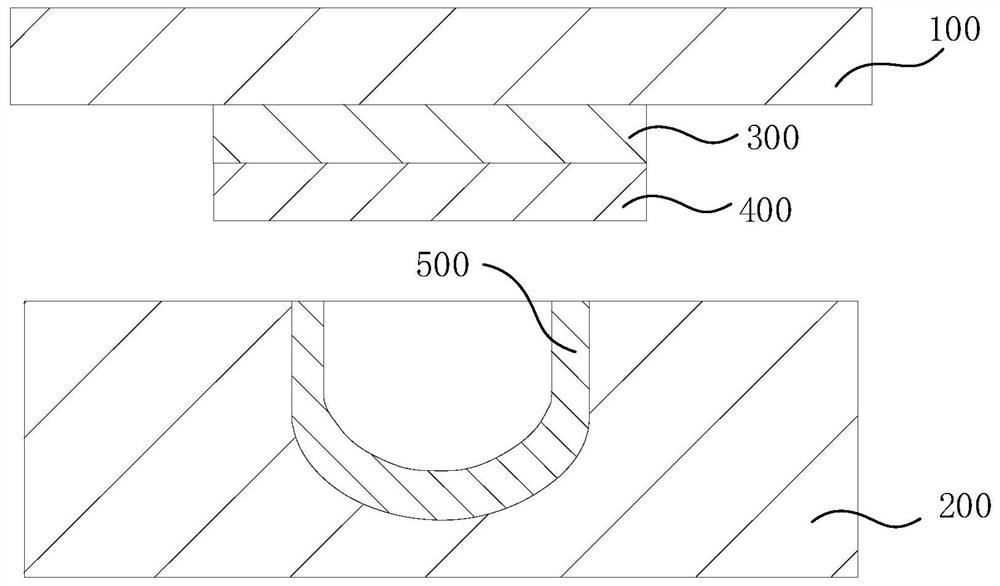

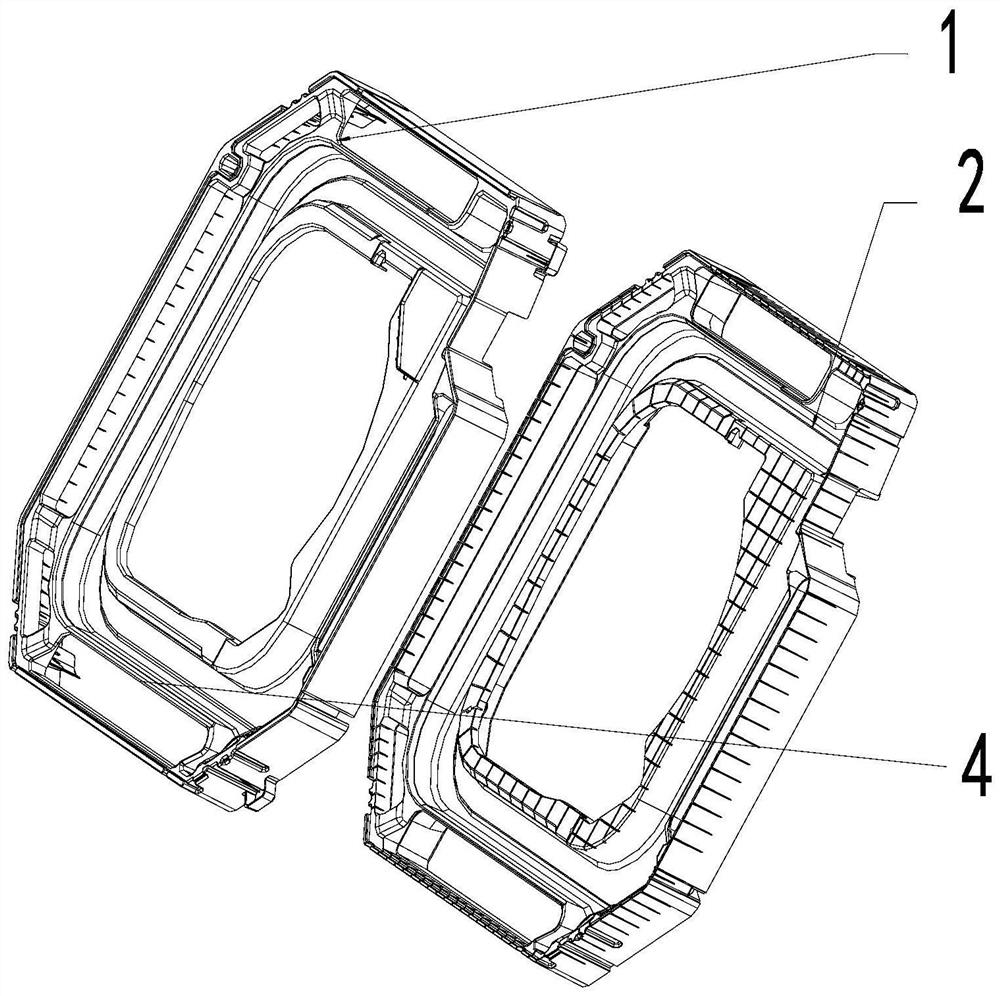

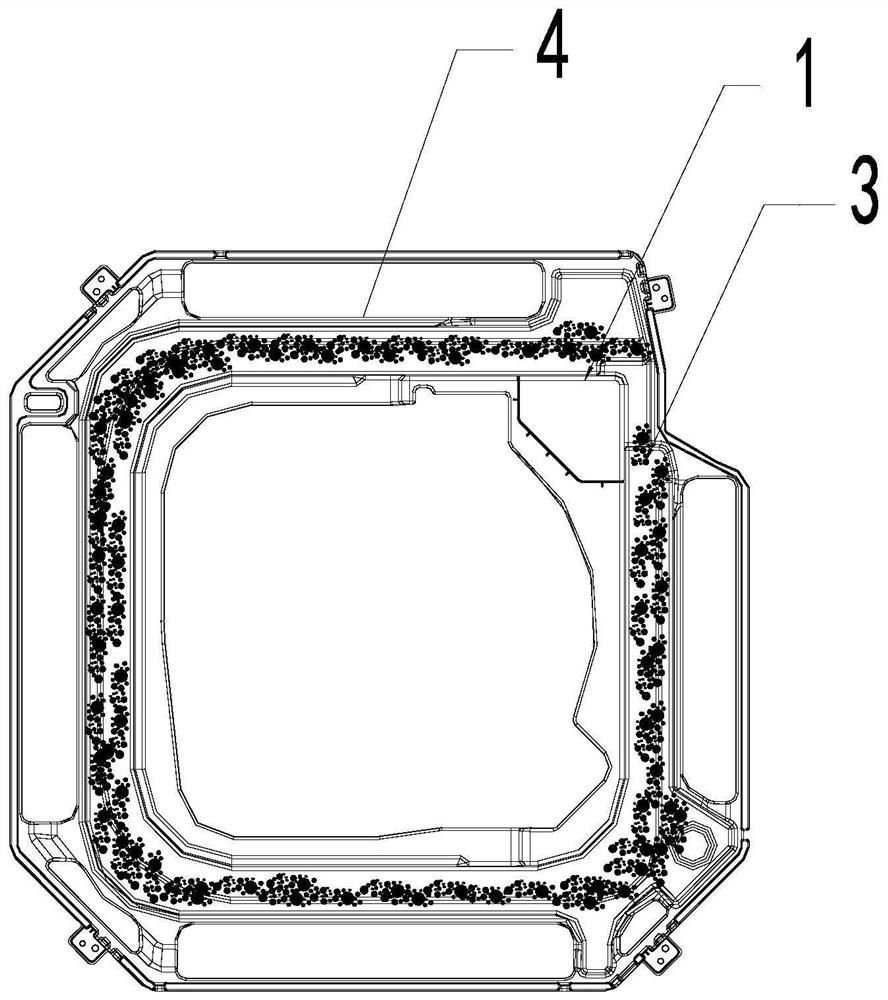

Molding fixture and thermoplastic molding device

ActiveCN111546618BAvoid blockingAvoid being unable to dischargeDomestic articlesEngineeringMechanical engineering

The invention relates to a molding jig and a thermoplastic molding device, wherein the molding jig is used in the thermoplastic film sticking process, and the upper surface of the molding jig is provided with a platform part, a curved surface bearing part, a slope transition part and a first exhaust port , the curved surface bearing part is used to carry the object to be stuck, the platform part surrounds the curved surface bearing part, the slope transition part is located between the platform part and the curved surface bearing part, and the first exhaust port is located at the slope transition part; The exhaust hole connected with the exhaust port. The molding jig and thermoplastic molding device of the present invention can provide a slope transition part between the platform part and the curved surface bearing part of the molding jig, and arrange the first exhaust port on the slope transition part instead of the platform part, so that Avoid the problem of blocking the exhaust port when the film material touches the platform during the film sticking process, thereby avoiding the problem that the sticking air bubbles cannot be discharged.

Owner:INTERFACE TECH CHENGDU CO LTD +2

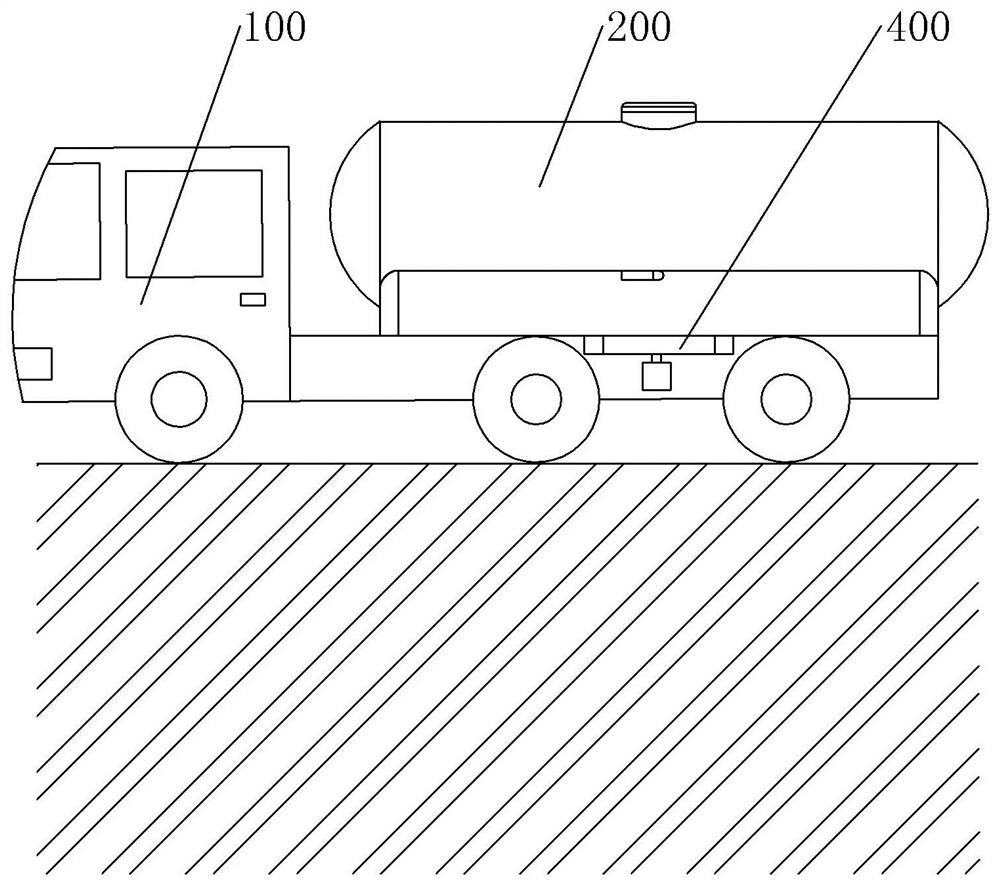

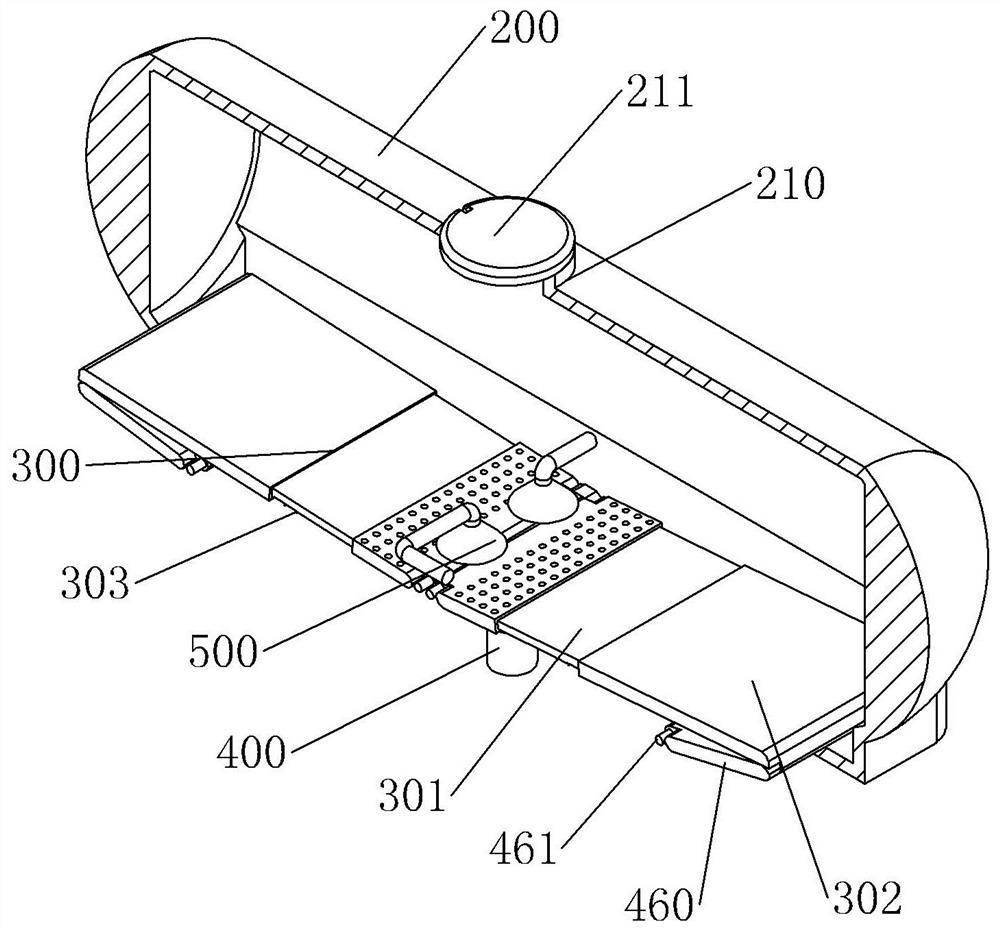

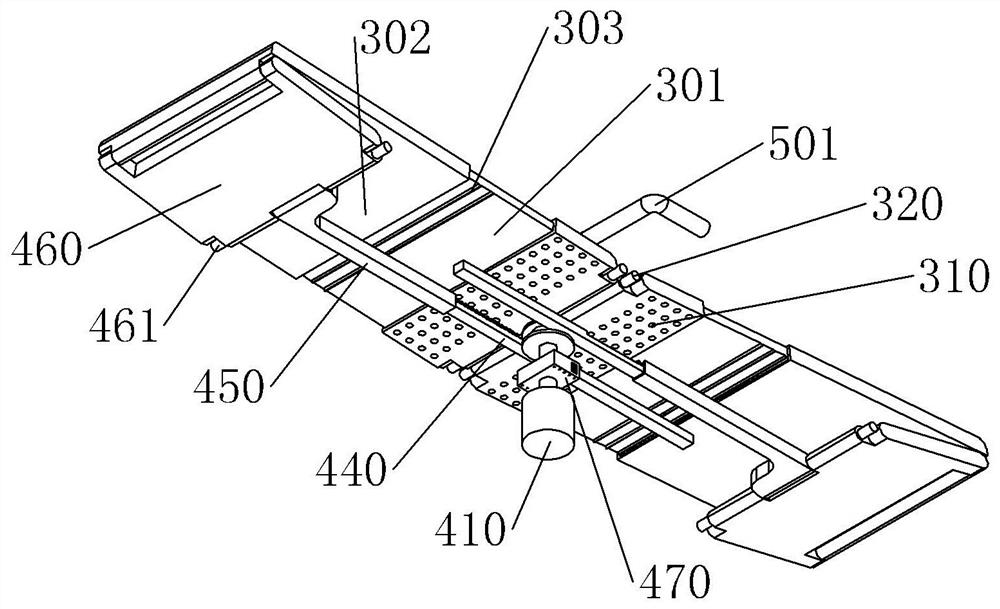

Powder and particle material transportation tank

ActiveCN114655587AImprove transportation efficiencyIncrease profitTank vehiclesBio-packagingGravity centerMaterial transport

The invention relates to the field of material transportation containers, in particular to a powder and particle material transportation tank. A powder and particle material transportation tank comprises a tank body, a transmission device, a discharging device and two flow guide plates, wherein the transmission device, the discharging device and the two flow guide plates are arranged in the tank body. Hinge shafts which are arranged left and right are hinged to the close ends of the two flow guide plates, and the hinge shafts can be mounted on the tank body in an up-and-down moving manner; the transmission device enables the two guide plates to rotate around the corresponding hinge shafts, so that the ends, away from the hinge shafts, of the guide plates are higher than the other ends; according to the conveying tank, the flow guide plate can rotate around the hinged shaft, in the conveying process, the transmission device does not act, the conveying tank can contain more materials, in the unloading process, the transmission device enables the end, away from the hinged shaft, of the flow guide plate to be higher than the end, close to the hinged shaft, of the flow guide plate, and powder and particle materials in the tank body are guided to the discharging device. The utilization rate of the internal space of the tank body is increased, the transportation efficiency of powder and particle materials is improved, meanwhile, the gravity center of the carrier loader is lowered, and safety accidents are avoided.

Owner:山东嘉通专用汽车制造有限公司

Water pan structure and patio machine

PendingCN112728748AHigh strengthPrevent water leakageDucting arrangementsCondensate preventionWater flowEnvironmental engineering

The invention provides a water pan structure and a patio machine. The water pan structure comprises an injection molding inner shell, a foam outer shell and an antibacterial structure, wherein the injection molding inner shell is arranged on the foam outer shell, and the antibacterial structure is arranged on the injection molding inner shell. According to the water pan structure and the patio machine, an inner cavity of a water pan is formed through injection molding, and an outer cavity of the water pan is formed through foaming in an injection molding inner cavity, so that the strength of the water pan is improved, water leakage of the water pan due to damage of the water pan is prevented, the plastic uptake procedures of metal inserts and plastic uptake layers are reduced, the cost is reduced, and the efficiency is improved; and meanwhile, the antibacterial structure is additionally arranged in the injection molding inner shell, so that the problem that because a large number of bacteria are liable to be gathered to hinder flowing of water flow and even form sticky masses, drainage of hydraulic components is blocked, and consequently water in the water pan of the patio machine cannot be drained can be effectively solved, and the running reliability of the patio machine is improved.

Owner:GREE ELECTRIC APPLIANCES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com