Efficient catalytic cracking device for petrochemical industry production

A catalytic cracking device, petrochemical technology, applied in catalytic cracking, petroleum industry, cracking, etc., can solve the problems of exhaust gas cannot be discharged, low filtration efficiency, catalytic cracking efficiency reduction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

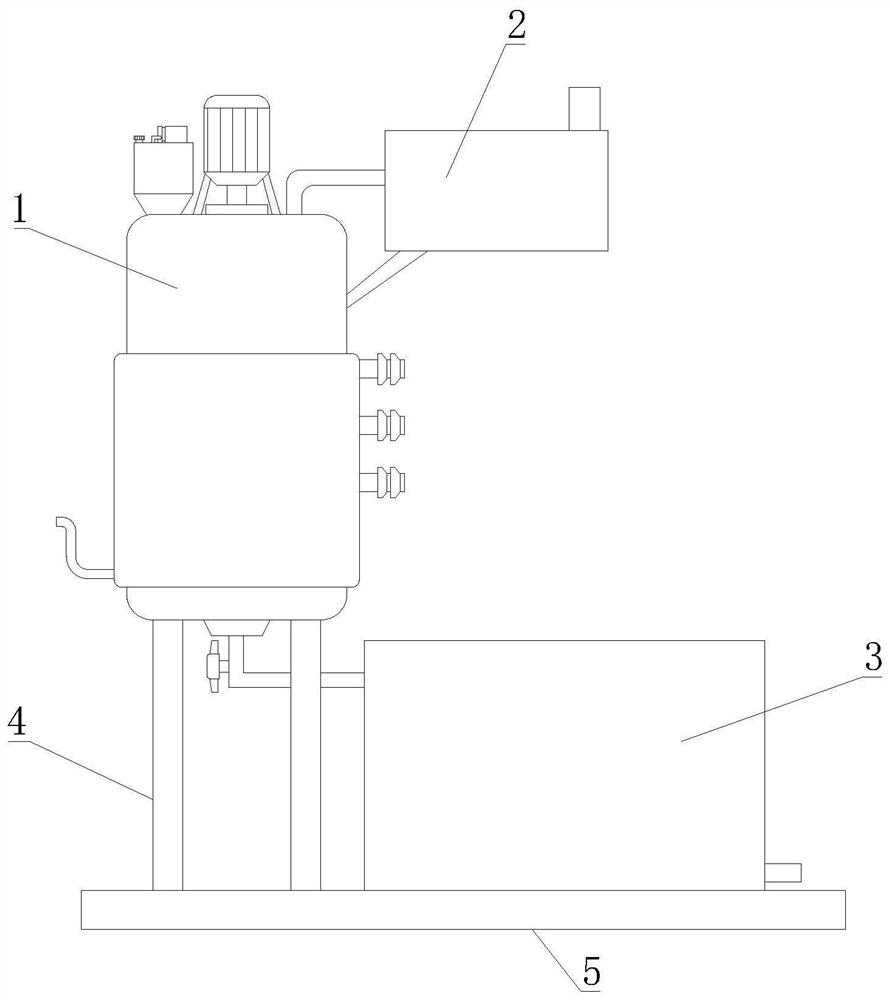

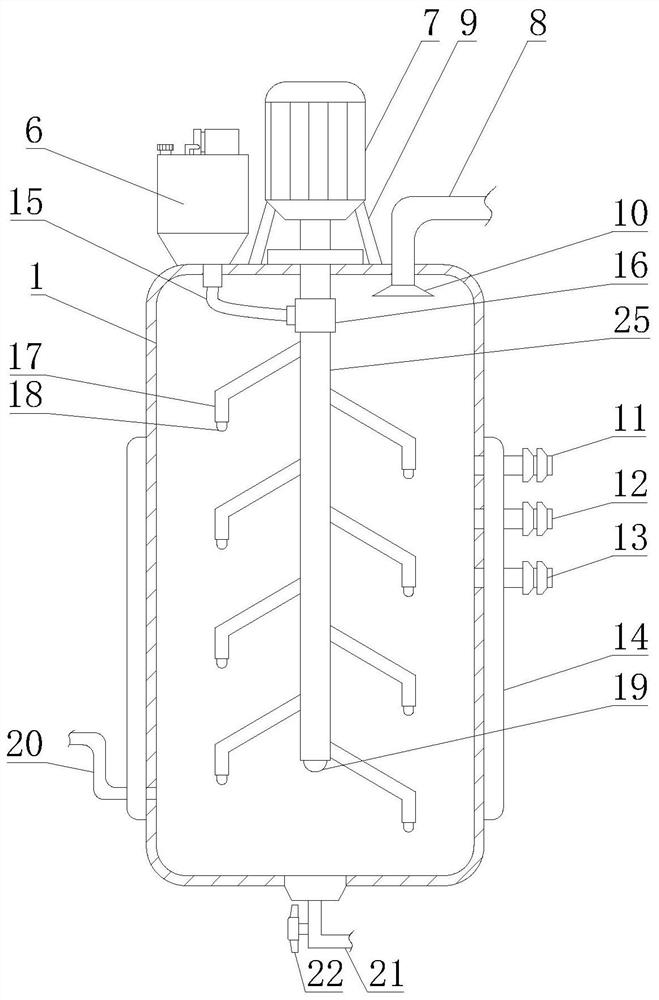

[0033] Such as Figure 1-Figure 7 As shown, the present invention provides a high-efficiency catalytic cracking unit for petrochemical production, including a catalytic cracking unit 1, a side support 34 is fixedly installed on the right side of the catalytic cracking unit 1, and a waste gas treatment unit 2 is fixedly installed on the top of the side support 34 , the four corners of the bottom of the catalytic cracking unit 1 are fixedly installed with supporting legs 4, the bottom of the catalytic cracking unit 1 is fixedly installed with a sewage tank, the bottom of the sewage tank is fixedly installed with a sewage pipe 21, and the right side of the sewage pipe 21 is fixedly installed with a sewage treatment device 3. The sewage pipe 21 runs through the left inner wall of the sewage treatment device 3, the bottom of the sewage treatment device 3 is fixedly installed with a bottom plate 5, the bottom of the support legs 4 are fixedly installed on the top of the bottom plate ...

Embodiment 2

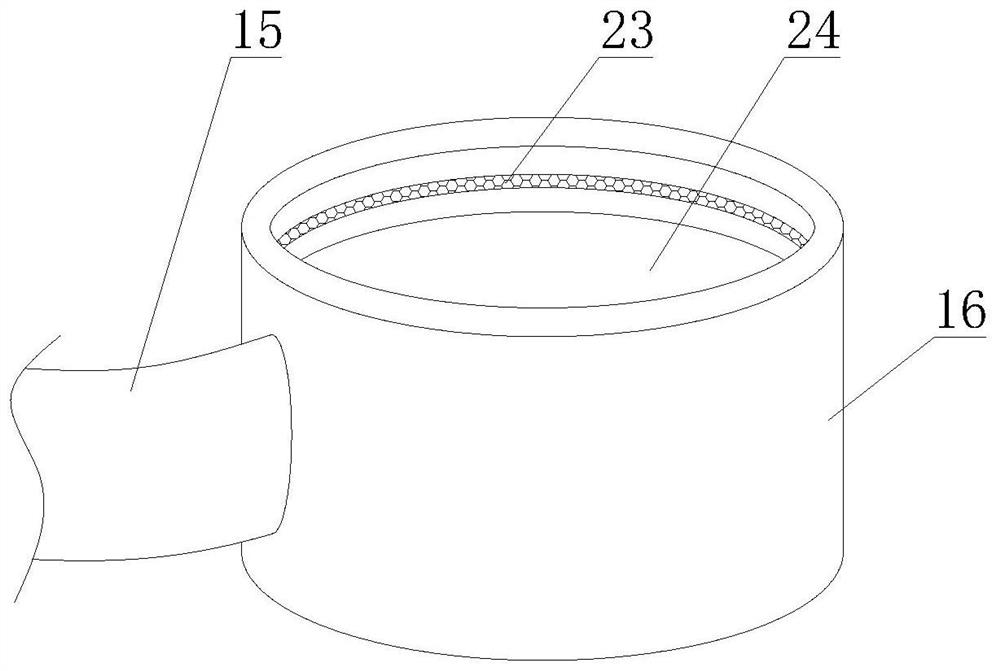

[0038] Such as Figure 1-Figure 7 As shown, on the basis of Example 1, the present invention provides a technical solution: the bottom of the catalyst tank 6 is provided with a feeding port, the feeding port runs through the left side of the top of the catalytic cracking unit 1, and the bottom of the feeding port is fixed Connected with a catalyst delivery pipe 15, one end of the catalyst delivery pipe 15 is fixedly connected with a hollow delivery ring 16, the inner wall of the hollow delivery ring 16 is provided with a rubber sealing ring 23, and the inner wall of the hollow delivery ring 16 is provided with a delivery notch 24, the hollow delivery ring The inner wall of 16 is socketed with stirring shaft 25, and the socket of stirring shaft 25 is provided with a groove, the top of the groove is provided with an upper sealing ring groove 26, the bottom of the groove is provided with a lower sealing ring groove 27, and the middle part of the groove An input notch 28 is provid...

Embodiment 3

[0040] Such as Figure 1-Figure 7 As shown, on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: an exhaust pipe 8 runs through the left side of the exhaust gas treatment device 2, and an exhaust gas distribution cover is fixedly installed on the right side of the exhaust pipe 8 29. The exhaust gas distribution cover 29 is fixedly installed on the inner side of the exhaust gas treatment device 2, and the two ends of the inner wall of the exhaust gas treatment device 2 are evenly distributed with filter element holders 30, and the inner sides of the filter element holders 30 are fixedly installed with air filter elements 31, and the air filter elements 31 are distributed in the exhaust gas On the right side of the distribution cover 29, the right side of the air filter element 31 is provided with an air monitor 46, the right side of the air monitor 46 is fixedly installed with a support frame, and the right side of the support frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com