Impulse-type grouting apparatus with variable voltage variable frequency

A grouting device and a pulsed technology, applied in the field of pulsed grouting devices, can solve problems such as the inability to provide grouting pressure, and achieve the effects of flexible and adjustable grouting mode, high grouting frequency, and increased discharge speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

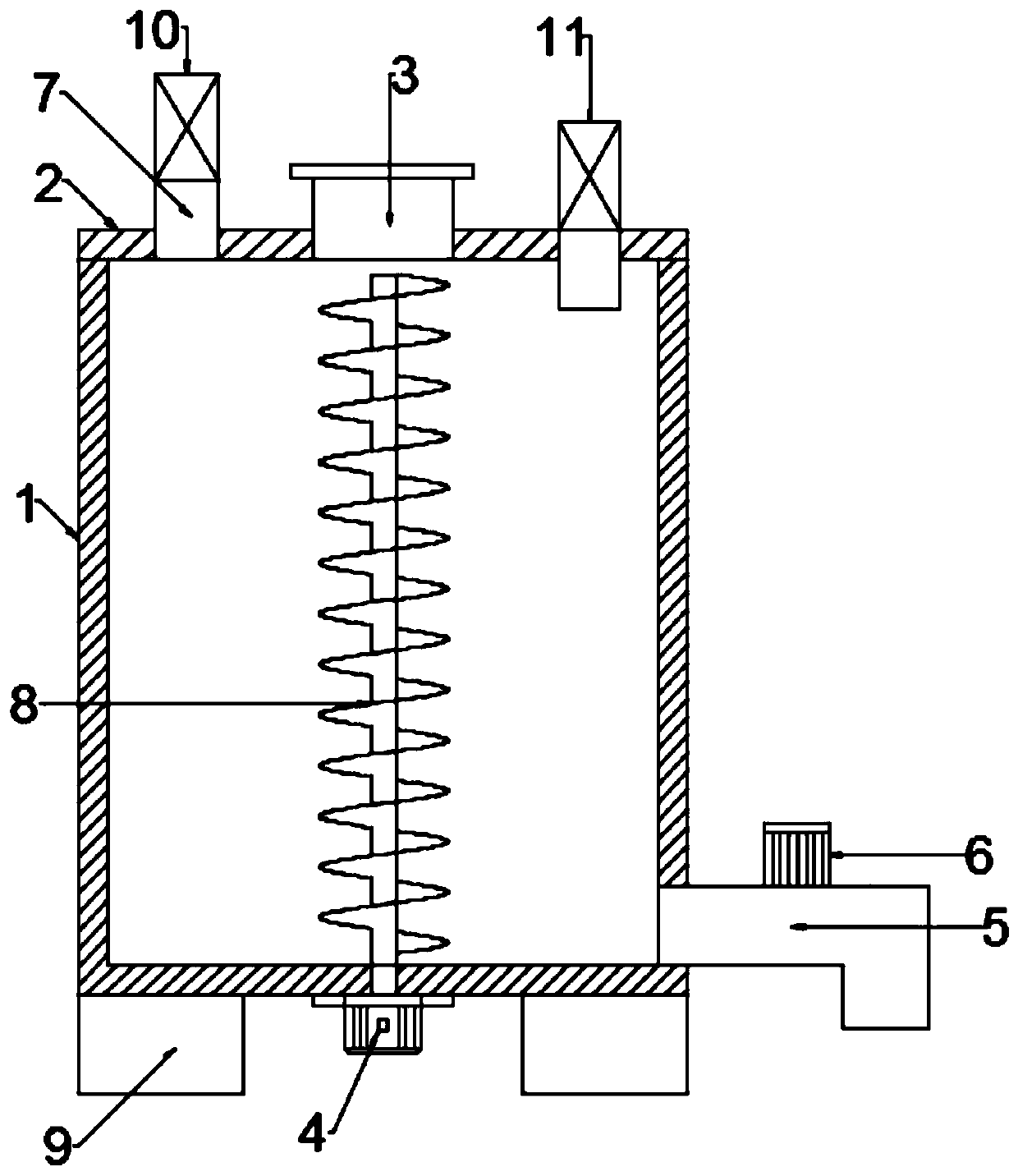

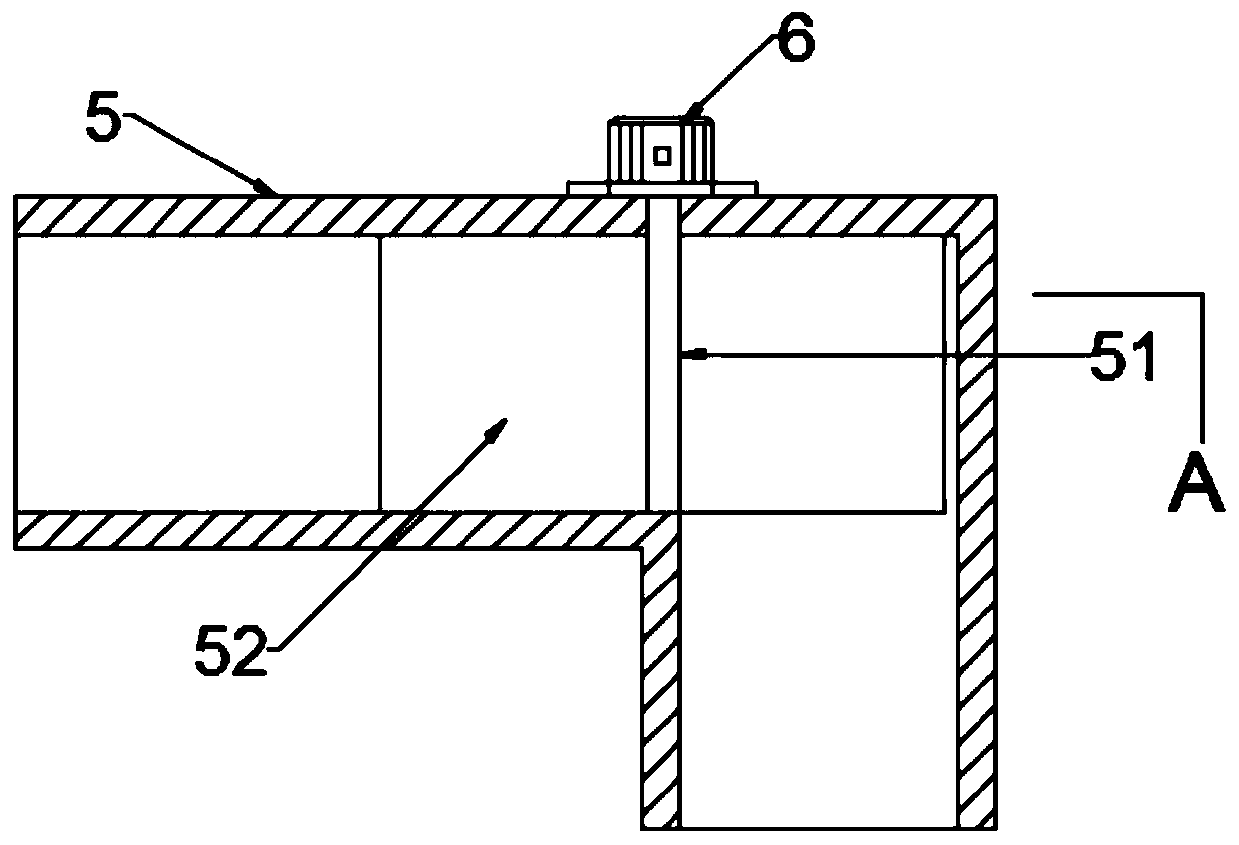

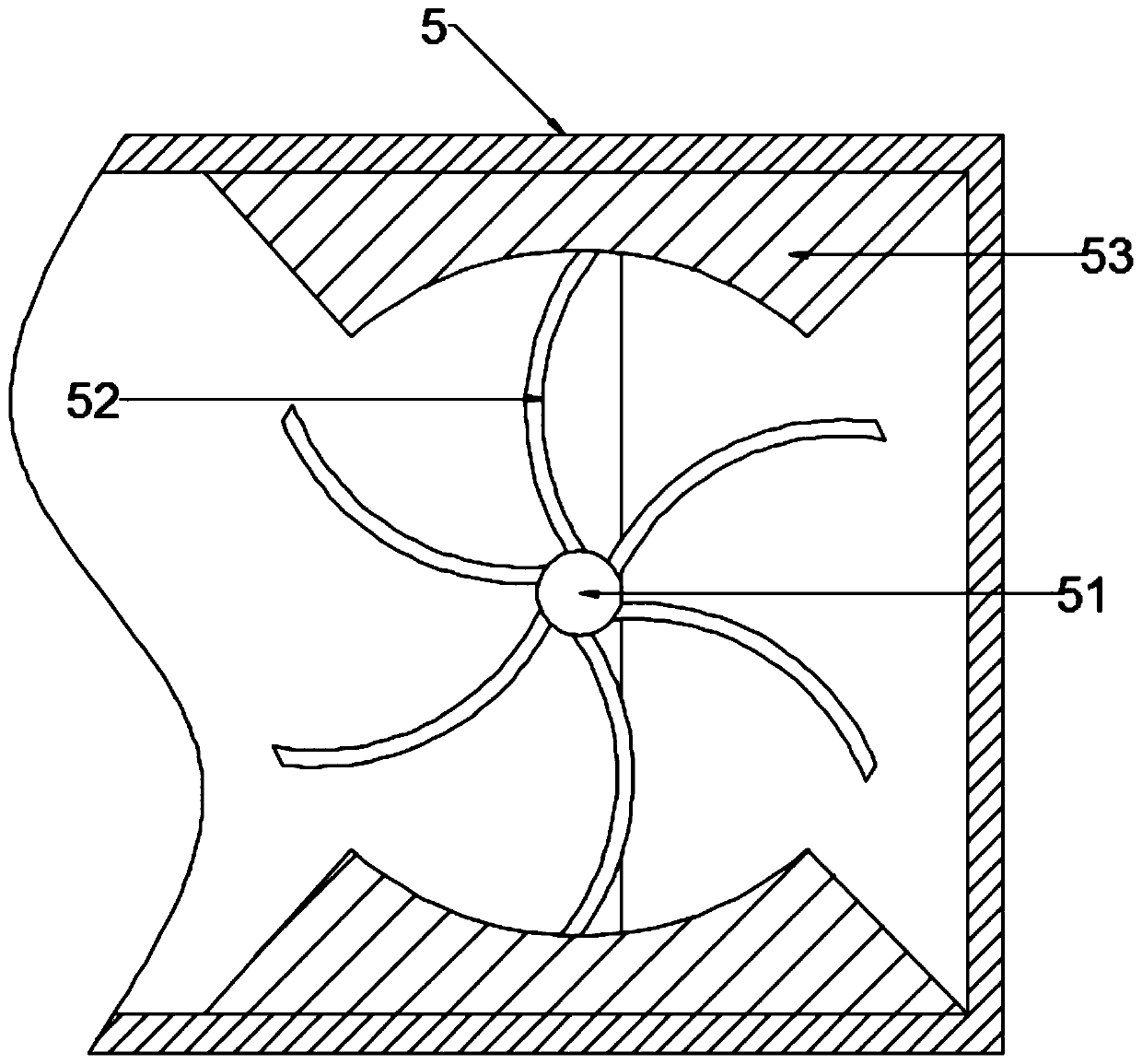

[0025] see Figure 1~3 , in an embodiment of the present invention, a pulse type grouting device with variable frequency and variable pressure includes a cylinder body 1, on which the upper cover 2 is movable assembled by riveting, and the upper cover 2 is connected with a The grouting pipe 3, the lower end of one side of the cylinder body 1 is also connected with the grouting pipe 5, and the upper cover 2 is also connected with two sets of pressure control valves 7 that limit the flow direction and are used for pressure regulation. The pressure valves 7 are all connected to the inside and outside of the cylinder body 1, and the upper ends of the two groups of pressure control valves 7 are respectively connected with an exhaust fan 10 and a blower fan 11, and the cylinder body 1 is also connected with a homogeneous structure for stirring. The grout pipe 5 is also provided with a valve structure to control the flow rate through rotation, and the valve structure is driven by the...

Embodiment 2

[0032] see Figure 4~5 , in the embodiment of the present invention, a pulse type grouting device with variable frequency and variable pressure. The blockage structure in the trachea 71 is composed of a fixed bracket 72 fixedly connected to one end of the air guide tube 71, and the fixed bracket 72 is connected to the blockage structure through an elastic member 74; the blockage structure includes a sliding fit arranged on the guide tube The sliding bracket 73 in the trachea 71 and the sealing gasket 76 connected by the connecting rod 75, the fixed bracket 72 and the sliding bracket 73 are all cross-shaped structures, and the sealing gasket 76 diameter and the outer circumference of the end of the airway tube 71 are The diameters are matched, and the sealing gasket 76 and the end of the airway tube 71 are attached with a cushion layer on the opposite side. The sealing gasket 76 is movably attached to the end surface of the airway tube 71 when the elastic member 74 has no exter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com