Fruit picking machine

A technology for picking machines and fruits, applied in the directions of picking machines, harvesters, agricultural machinery and implements, etc., can solve the problems of low picking efficiency, inability to pick, and occupy a large space, and achieve the effect of flexible operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

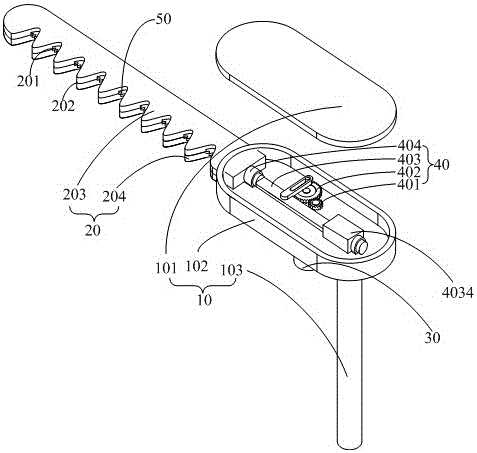

[0019] The fruit picking machine includes a picking machine housing 10, a driving mechanism 30, a transmission mechanism 40, a cutting mechanism 50, a fruit protection introduction comb 20, a power supply picking machine housing 10 and a fruit protection introduction comb 20. The transmission mechanism 40 is arranged on the picking In the machine housing 10, one end of the cutting mechanism 50 is a connection end, the connection end is connected with the transmission mechanism 40, the other end of the cutting mechanism 50 is a cutting end, and the cutting end is arranged in the fruit protection introduction comb 20, and the driving mechanism 30 is arranged in the picking On the outer wall of the machine housing 10, the driving mechanism 30 passes through the picking machine housing 10 and is connected with the transmission mechanism 40, and the driving mechanism 30 pushes the cutting mechanism 50 to reciprocate through the transmission mechanism 40; The mechanism 30 is connecte...

Embodiment 2

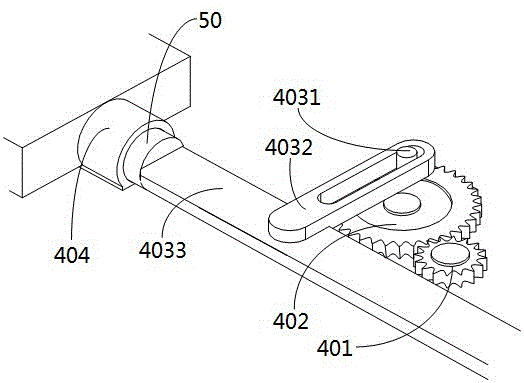

[0028] The difference between Embodiment 2 and Embodiment 1 lies in the traction mechanism 403 in the transmission mechanism 40 , and other structures are the same as Embodiment 1. For details, please refer to Figure 4 The traction mechanism 403 in Embodiment 2 includes a rotating rod 4035 and a second linkage rod 4036. One end of the rotation rod 4035 is fixed on the driven gear 402, and the other end of the rotation rod 4035 is connected to the second linkage rod 4036. One end is rotationally connected, and the other end of the second linkage rod 4036 is hinged with the cutting mechanism; one end of the second linkage rod 4036 is provided with a through hole matched with the rotation rod 4035, so that the rotation rod 4035 rotates in the through hole, and the rotation rod 4035 rotates around the axis of the driven gear 402, and at the same time, the rotating rod 4035 drives the second linkage rod 4036 to swing, so that the second linkage rod 4036 drives the cutting structur...

Embodiment 3

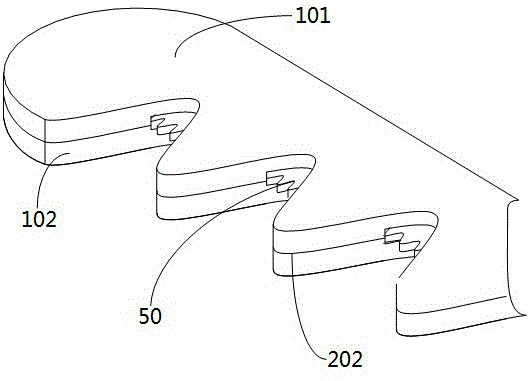

[0030] The difference between embodiment 3 and embodiment 1 lies in the fruit protection guide comb 20 and the cutting mechanism 50 of the picking machine housing 10, and other structures are the same as embodiment 1. For details, please refer to Figure 5 Comb teeth 202 are set on both sides of the fruit protection import comb 20, a cutting guide groove 201 is set in the fruit protection import comb 20, and the cutting mechanism 50 is arranged in the cutting guide groove 201. The cutting mechanism 50 includes a cutting saw blade, and the two sides of the cutting saw blade are arranged Sawtooth, a part of the serration is exposed in the alveolar of the fruit protection import comb 20, after the fruit stem of the fruit enters the alveolar of the fruit protection import comb 20, the cutting saw blade reciprocates, and the sawtooth cuts the fruit stem reciprocally to cut off the fruit stem.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com