Integrated device for sedimentation and dust collection and method for treating rhenium-containing dust with the device

A technology of fume and sedimentation zone, applied in chemical instruments and methods, separation methods, combined devices, etc., can solve the problems of low dust collection efficiency, difficulty in normal operation of the system, and reduced rhenium recovery rate, so as to reduce the dust collection pressure and avoid the Coagulation loss, the effect of ensuring the recovery rate of rhenium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

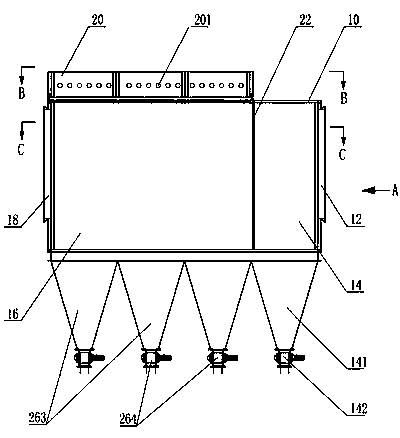

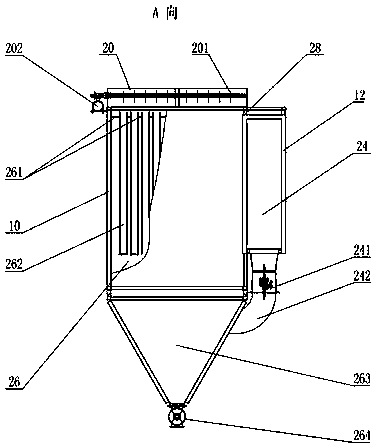

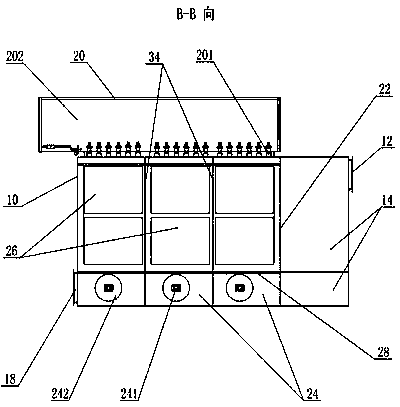

[0035] A rhenium production plant extracts rhenium from rhenium-containing molybdenum concentrates by means of fluidized roasting. The oxidation roasting temperature is 560-700°C, and the oxygen partial pressure is 23-180KPa. Flue gas and dust form rhenium-containing fume, which accounts for 34-36% of the roasted material. Figure 1-5 The settling and dust collection integrated device shown is for dust collection operation, and the concentration of rhenium-containing soot dust is 58 g / Nm 3 , The dust temperature is 540°C.

[0036] The settling dust collection integrated device used in this embodiment to collect dust from rhenium-containing dust, such as figure 1 As shown, there is a housing 10, a rhenium-containing fume inlet 12, a sedimentation dust collection system, a backflushing system 20, and a rhenium-containing gas outlet 18 for dust removal. The rhenium-containing fume inlet 12 is used to introduce rhenium-containing fume into the device, and dust removal The gas ou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com