An in-situ remediation method for deep heavy metal-contaminated soil

A technology for in-situ remediation of polluted soil, applied in the restoration of polluted soil, etc., can solve the problems of large amount of slurry returning, poor treatment effect of heavy metals, difficult in-situ treatment, etc., and achieve high utilization efficiency, excellent treatment effect, and treatment short cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

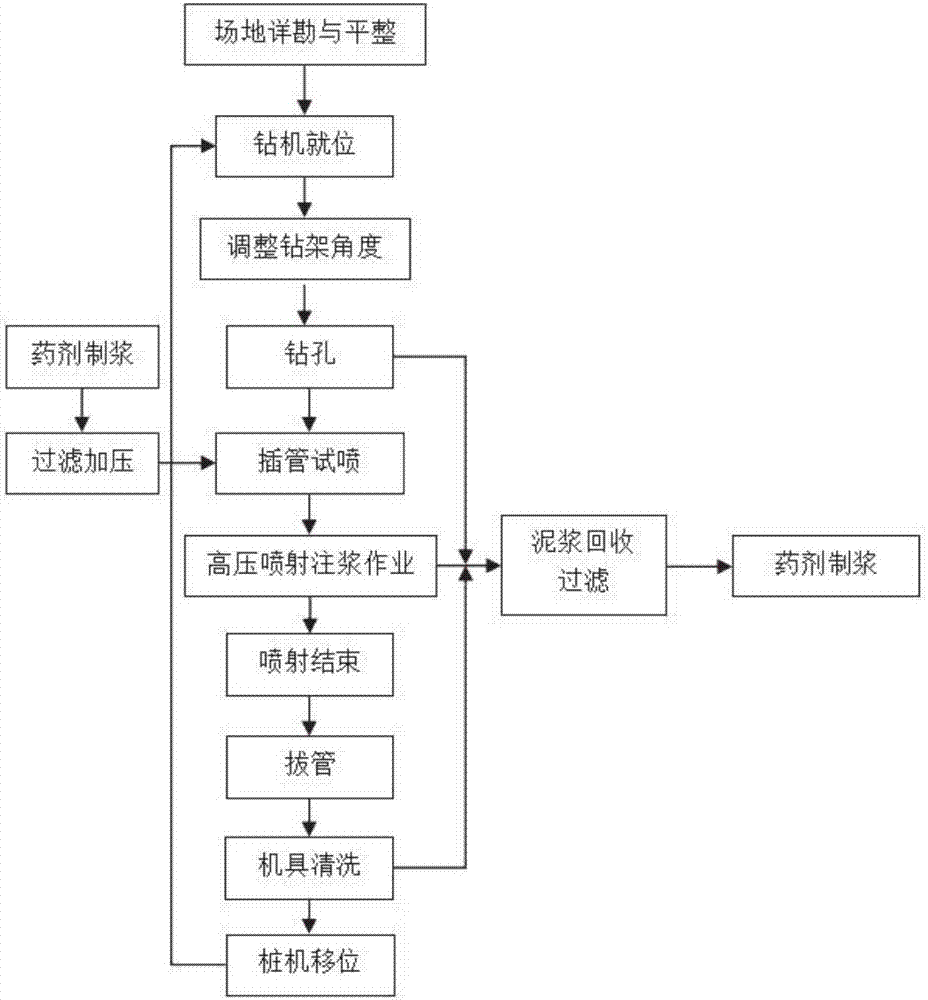

[0053] This embodiment is a treatment project of a city's historical waste residue site, and the process flow is as follows figure 1 As shown, the specific steps are as follows:

[0054] Step (1) This embodiment is aimed at a historical waste residue site, the pollutants are 6-14m below the surface, and the area is about 20000m 2 , the amount of contaminated soil is about 100,000 tons, and the amount of off-site treatment is too large. After sampling and testing, it is Class II industrial solid waste. The main heavy metals that exceed the standard are lead and zinc. The concentration of lead in the sample water is 5.6mg / L, and zinc is 2.78mg / L. The requirement is that the leaching solution after treatment should meet the "Comprehensive Discharge Standard for Sewage GB8978-1996".

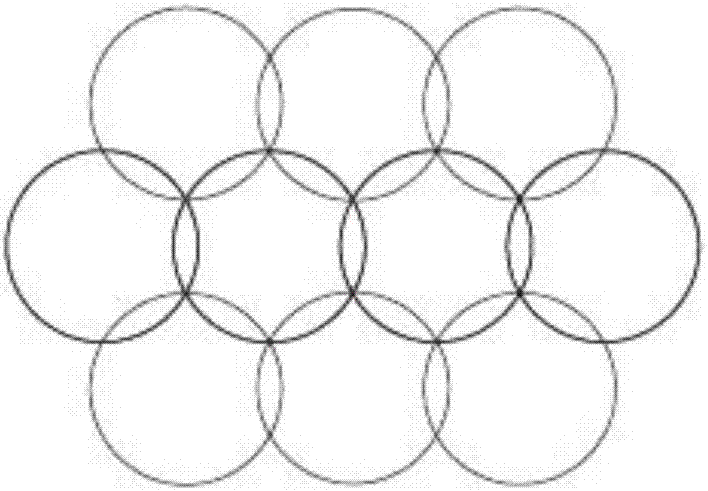

[0055] Step (2) After systematic geological exploration and sampling inspection, site leveling and pile testing, the double-pipe rotary spraying method is adopted for construction, and the process ...

Embodiment 2

[0060] Mine tailings treatment in a certain city, the process is as follows figure 1 As shown, the details are as follows:

[0061] (1) This example is aimed at the mine tailings site of a lead mine in a certain city. Due to irregular mining behaviors many years ago, the mining tailings were illegally dumped into a valley near the mine without reasonable disposal, with a total of 60,000 cubic meters. The environment has had an extremely bad impact. After sampling and testing, the main pollutants are lead, zinc, copper, and cadmium. After the treatment, the industrial solid waste reaching Class I will be closed in situ for disposal.

[0062] Step (2) After systematic geological exploration and sampling testing, site leveling and pile testing, the three-pipe rotary spraying method is adopted for construction. The process parameters are: slurry pressure is 20-25MPa, compressed air pressure is 0.7-0.8MPa, and high-pressure water pressure is 40~45MPa, rotation speed 5~10r / min, l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com