Glasses pipe processing device and processing method

A processing device and technology for spectacle tubes, applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of low work efficiency, cumbersome operation steps, low production quality of spectacle tubes, etc., and achieve high product quality and improved work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Embodiments of the present invention are described in detail below:

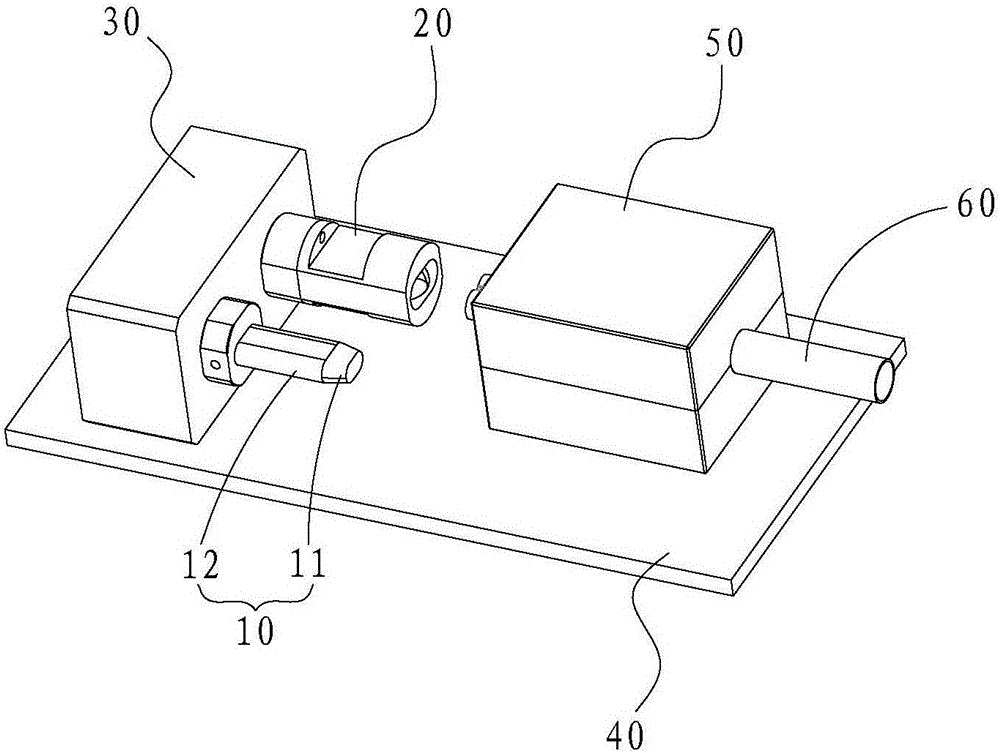

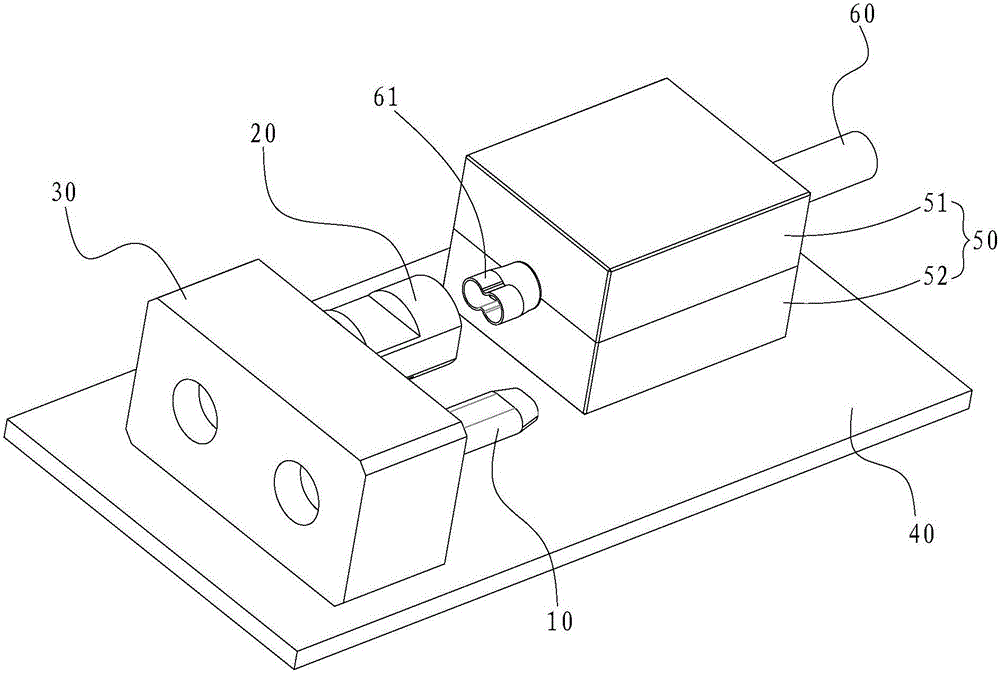

[0038] Such as figure 1 , 2 As shown, the spectacle tube processing device of the present invention includes a punch die 10 , a pressing die 20 and a driving mechanism 30 .

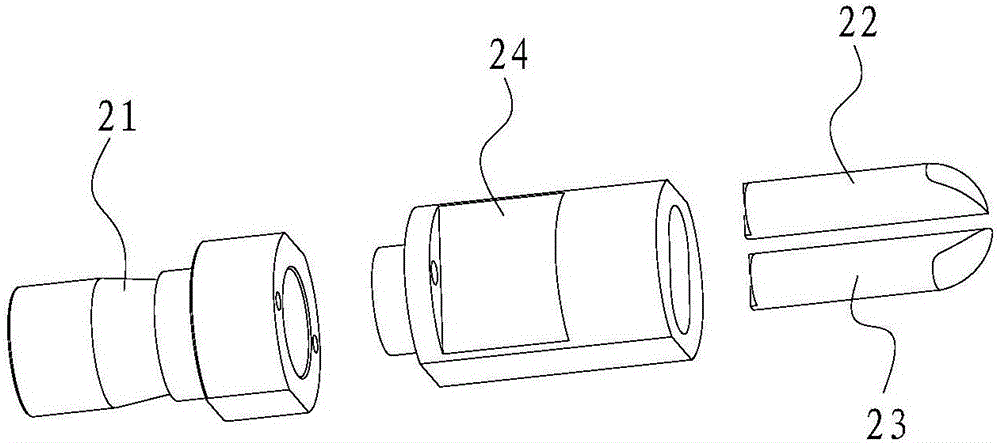

[0039]The punch die 10 includes a first stamping section 11 and a second stamping section 12 connected. The cross sections of the first stamping section 11 and the second stamping section 12 are oblong or elliptical. The area of the cross section of the first stamping section 11 gradually decreases in the direction away from the second stamping section 12, so that the first stamping section 11 is convenient to punch into the pipe fitting 60 through the port of the pipe fitting 60, and the first stamping section 11 The process of punching the segment into the tube 60 changes the cross-section of the end of the tube 60 from a circular shape to an oval shape. However, the cross-sectional area of the second stamping section 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com