Active compliance control method for hydraulic drive unit of legged robot

A drive unit, active compliance technology, applied in the direction of program-controlled manipulators, manipulators, manufacturing tools, etc., can solve problems such as irreparable, reduced impact resistance of robots, damage, etc., and achieve precise stiffness control and good two-way damping effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with accompanying drawing:

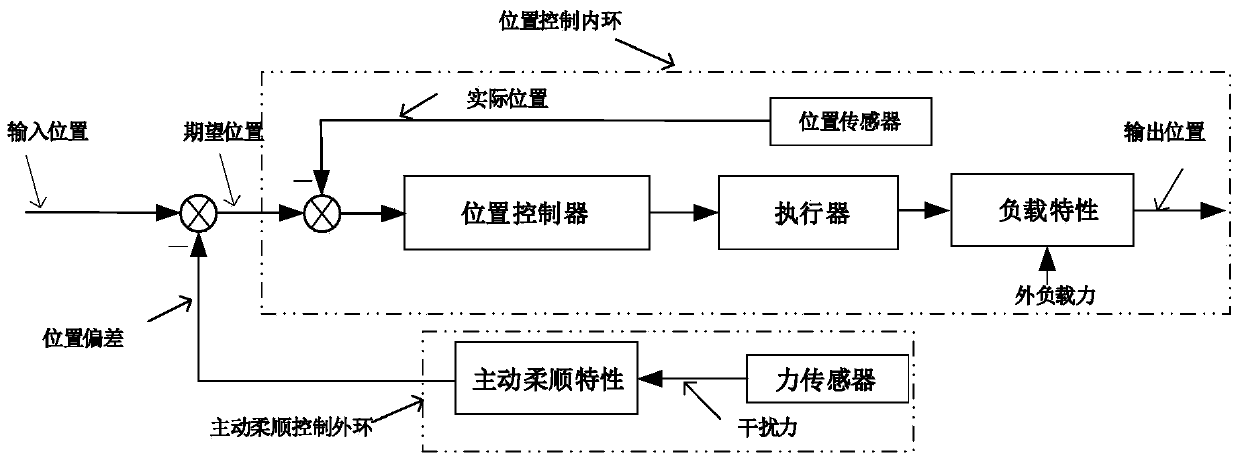

[0046] like figure 1 As shown, when the hydraulic drive unit receives a load force, the active compliance control outer loop will produce a corresponding position deviation, which will affect the input position to form a new expected position signal, and the expected position signal enters the position control inner loop to form a new Output the position to make the position control system have active compliance characteristics.

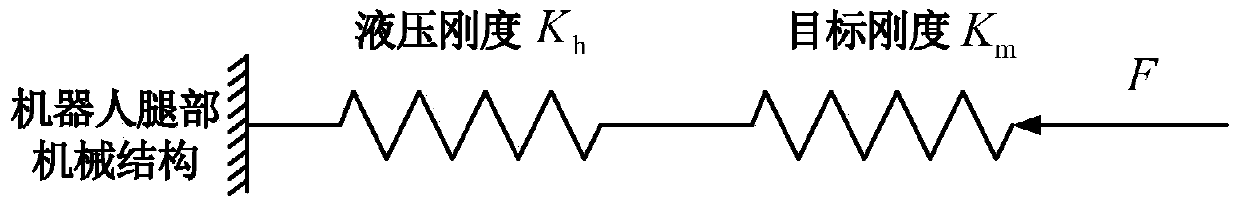

[0047] like figure 2 As shown, the inherent stiffness of the hydraulic system is the hydraulic stiffness, and the control of the system stiffness is equivalent to connecting a target stiffness in series on the basis of the hydraulic stiffness. When applying the traditional active compliance control method, due to the inherent characteristics of the hydraulic drive unit, its hydraulic stiffness is not infinite, and the external load force interf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com