Method for making register corrections on flatbed die-cutters

A platform type, die-cutting machine technology, used in printing presses, rotary printing presses, machining/deformation, etc., can solve problems such as waste pages and products no longer meeting quality requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

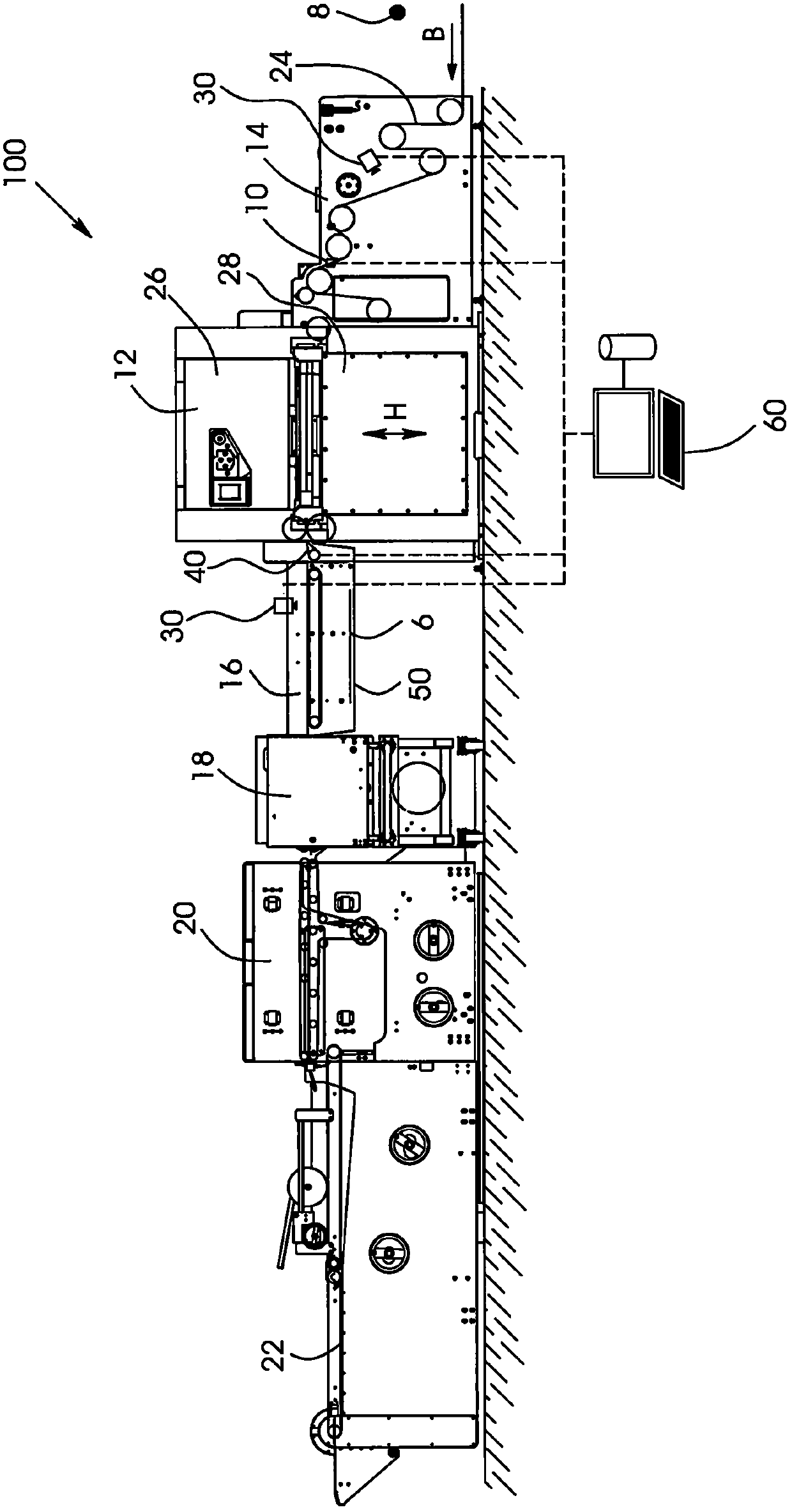

[0027] figure 1 A schematic diagram of a flatbed die cutter 100 according to the present invention is shown. The illustrated embodiment of the flatbed die-cutter 100 is modularly constructed in a horizontal configuration. In this schematic illustration, the processing of the printed material web 24 (such as folding boxes printed on a cardboard web in the previous rotary printing press 8) proceeds from right to left: from the web supply device 14, the printed material web The belt 24 reaches a flat-bed die-cutting station and / or an embossing station (hereinafter referred to as flat-bed die-cutting station 12) along the web running direction B, in which the The stroke movement H of the lower platen 28 towards the upper platen 26 causes the printing material web 24 to be cut into such that in a subsequent processing step individual printed products (eg folding box blanks) can be cut out of the printing material web 24 and separated from each other. Instead of or in addition to...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap