A New Type of Automobile Suspension

A kind of automobile suspension, a new technology, applied in the direction of suspension, elastic suspension, vehicle parts, etc., can solve the problems of exhaust gas, swing phenomenon, shock absorption effect, reduce vehicle ride comfort and ride comfort, etc., to improve safety Sex and riding comfort, shock absorption effect is obvious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

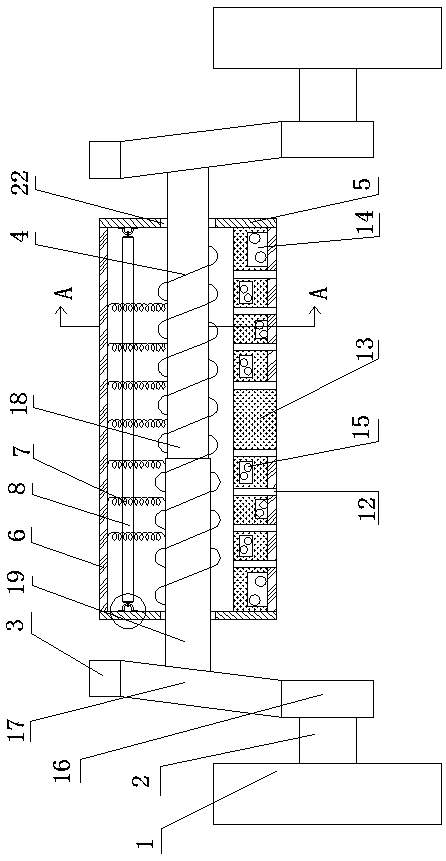

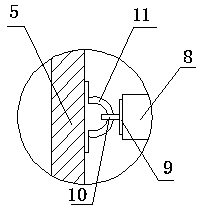

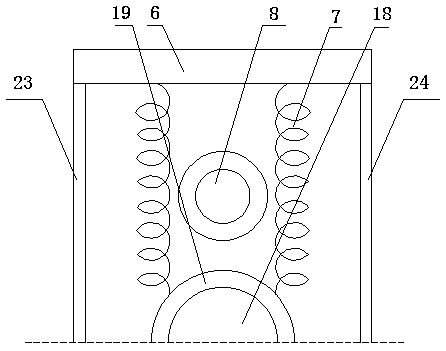

[0024] like Figure 1-5 Shown, a kind of novel automobile suspension, its composition comprises: wheel 1, spring, ball 15, the wheel center of wheel 1 is connected axle 2, and described axle 2 is provided with the hinge shaft 3 that is acute angle with horizontal, so A sleeve is connected between the struts 17 of the hinge shaft 3, a spring I4 is arranged on the sleeve, a shock absorber is arranged on the sleeve, and the shock absorber includes a support piece 5, and the The support sheet 5 is perpendicular to the sleeve, the sleeve passes through the support sheet 5, the top and bottom ends of the support sheet 5 are respectively connected to the rubber shock absorbing layer 6, and a rubber shock absorbing layer 6 is arranged on the upper layer. A set of spring II7 perpendicular to the sleeve, the bottom end of the spring II7 is welded on the sleeve, a transverse spring III8 is arranged between the spring II7, and the two ends of the spring III8 respectively pass through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com