Three-layer pallet fork device

A fork and double-layer technology, applied in the field of intelligent storage, can solve problems such as difficulty in adapting, and achieve the effect of extending the telescopic length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

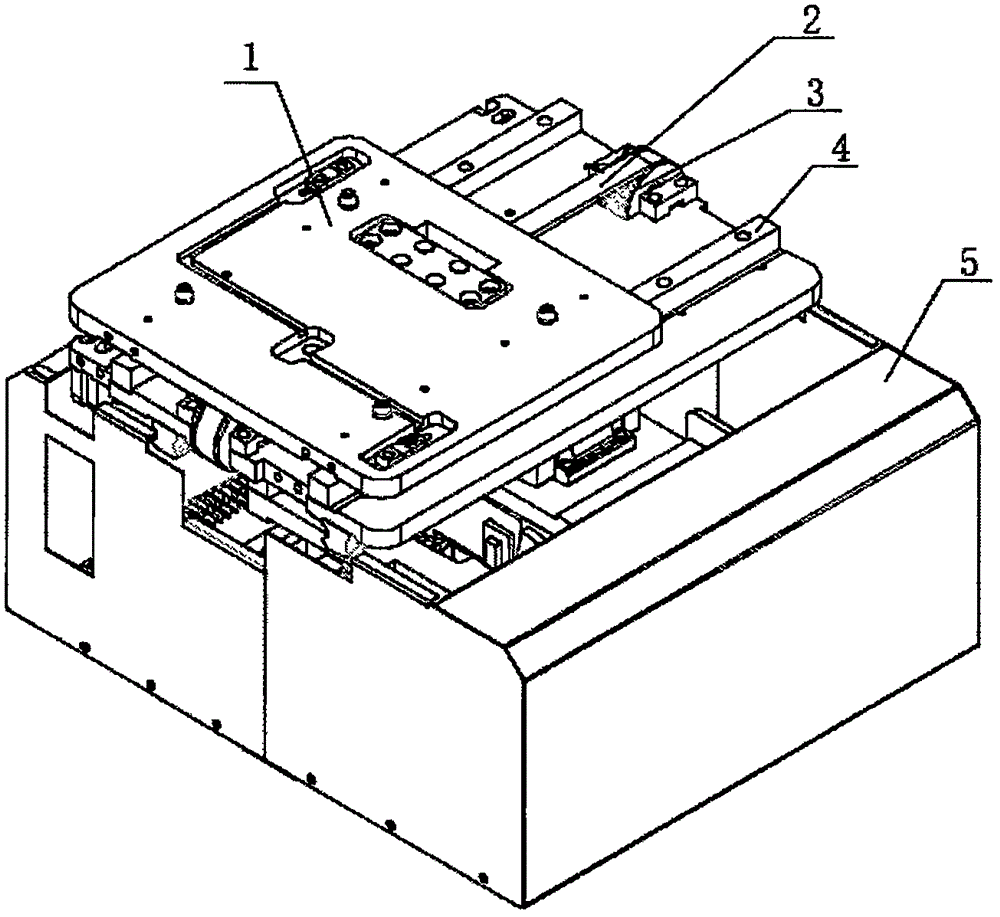

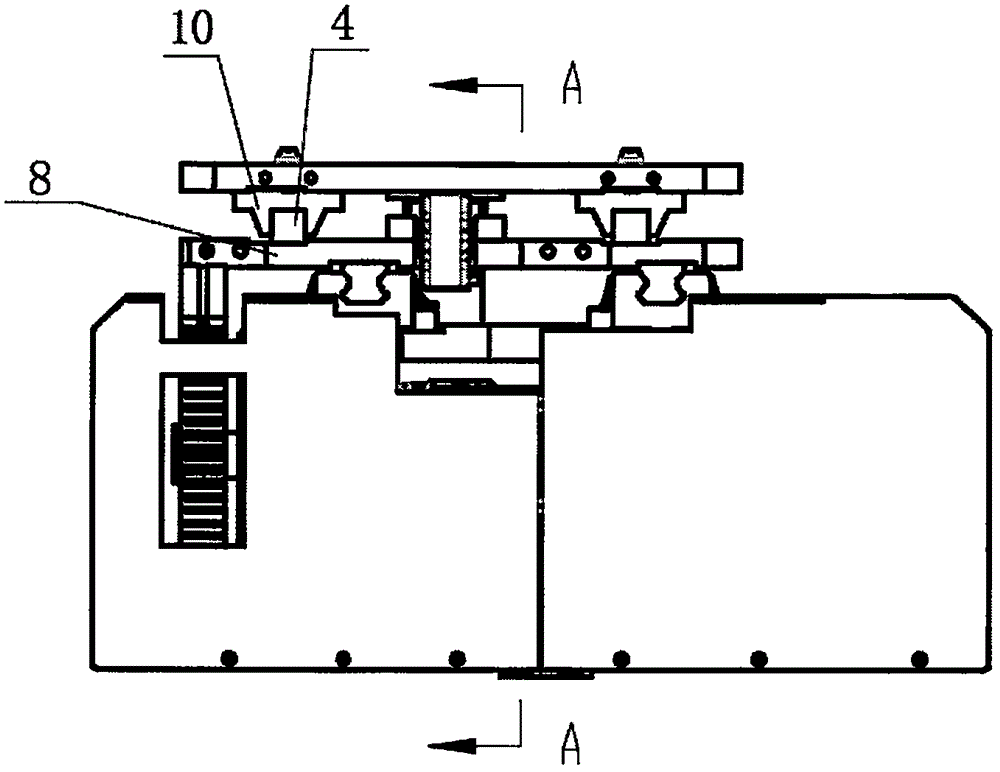

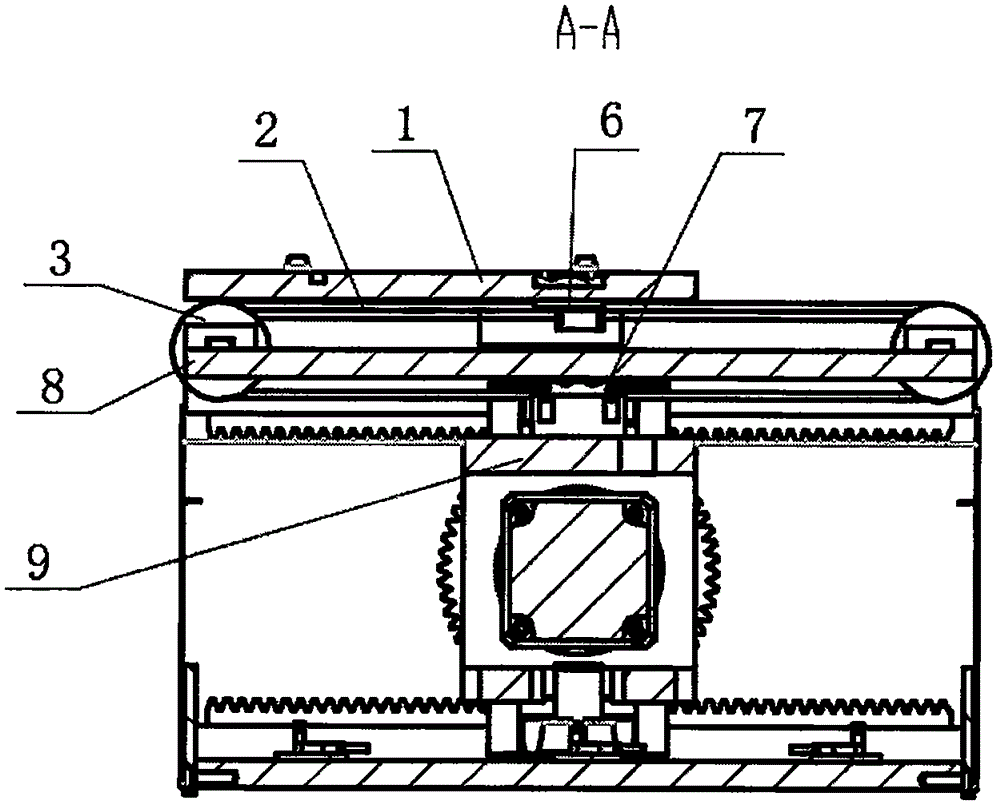

[0013] Such as figure 1 , figure 2 , image 3 As shown, the three-layer fork device includes an automatically retractable double-layer fork mechanism 5, a fork plate assembly 1, a timing belt pulley 3, a timing belt 2, and a linear guide rail 4. The automatic retractable double-layer fork mechanism 5 is provided with a retractable plate 8 and a fork mechanism body 9 . The upper surface of the telescopic plate 8 is rigidly connected with the linear guide rail 4 . A slide block assembly 10 is provided at the bottom of the fork plate assembly 1 , and the fork plate assembly 1 moves back and forth through the slide block assembly 10 and is installed on the linear guide rail 4 . The synchronous belt pulley 3 can freely rotate and is installed on the front and rear ends of the expansion plate 8 . Synchronous pulley 3 diameters should be greater than telescopic plate 8 thicknesses. The synchronous belt 2 is engaged with the front and rear two synchronous pulleys 3 and installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com