Adhesive tape roll mounting facility

A technology for tape rolls and equipment, applied in the direction of winding strips, thin material handling, transportation and packaging, can solve the problems of increasing production costs, time-consuming and laborious, low production efficiency, etc., to improve production efficiency and reduce production. cost, efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

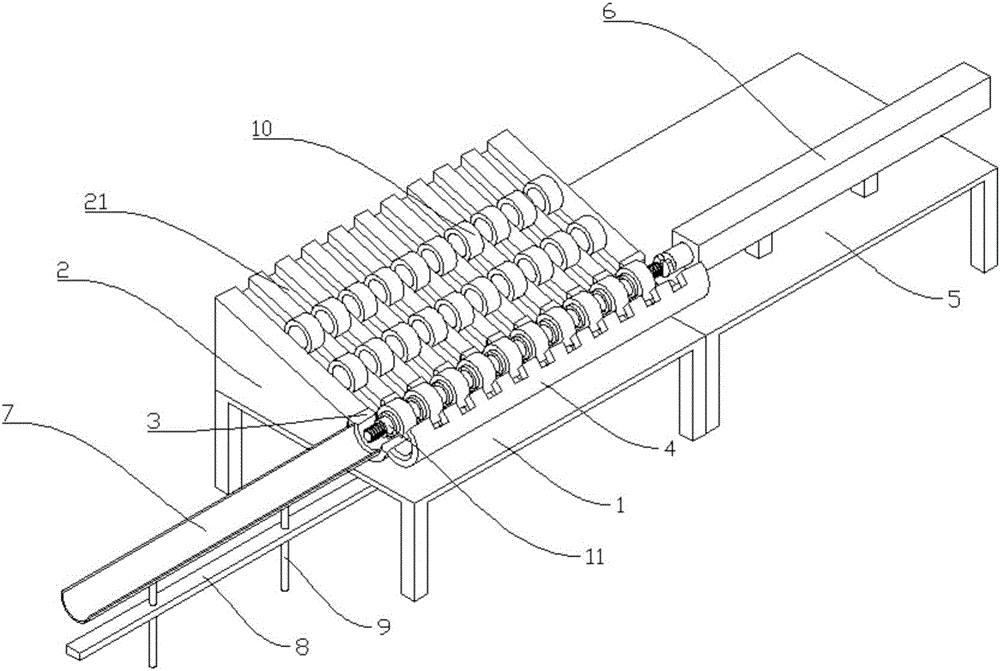

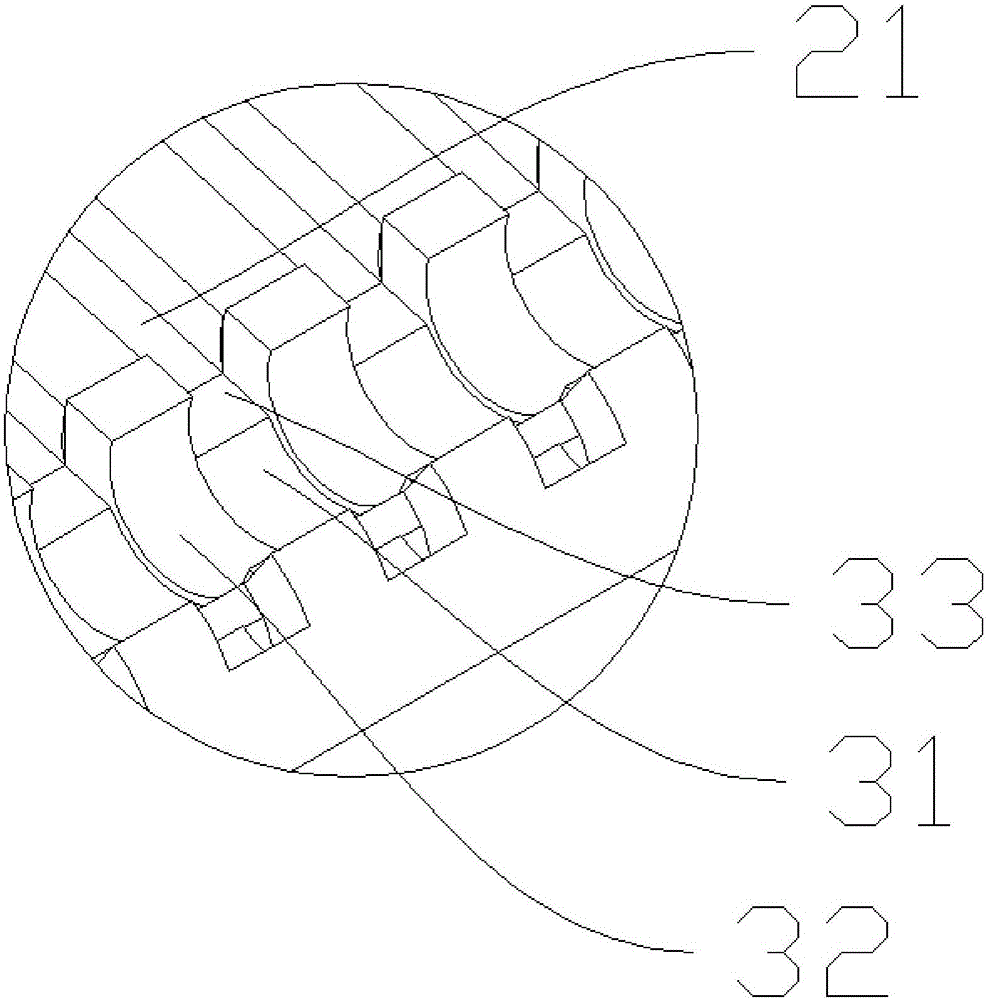

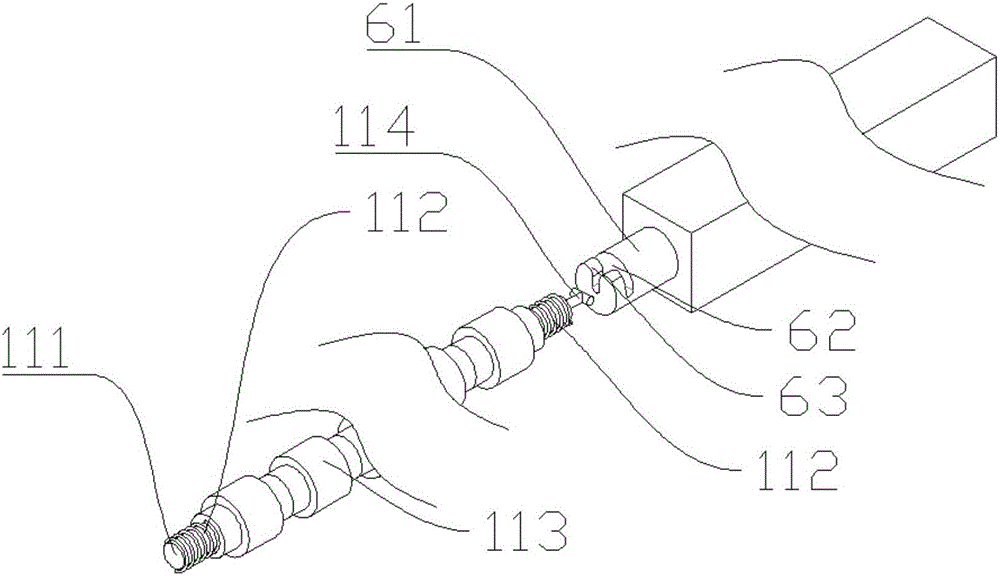

[0025] In order to achieve the purpose of the present invention, as shown in the figure, an embodiment of the present invention is: a tape roll sleeve equipment, including a blanking device, a lifting adjustment device, a roller shaft 11 and a roller shaft driving device, and the blanking device The device includes a blanking slide 2 and a positioning mold for the whereabouts of the tape roll 10; the lifting adjustment device is used to adjust the height of the roller shaft 11 relative to the positioning mold, and the roller shaft driving device is used to pull the roller shaft 11 into the positioning mold , the blanking slide 2 is provided with blanking grooves 21 distributed at intervals, the adhesive tape roll 10 is located in the blanking groove 21, the positioning mold includes an upper mold 4 and a lower mold 3, the upper mold 4 is connected to the lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com