Fibrofelt material and preparation method and application thereof

A fiber felt and fiber technology, applied in the field of fiber felt materials and its preparation, can solve the problems of increased pollution, secondary damage, etc., and achieve the effects of good sound absorption, low cost, and broad market application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

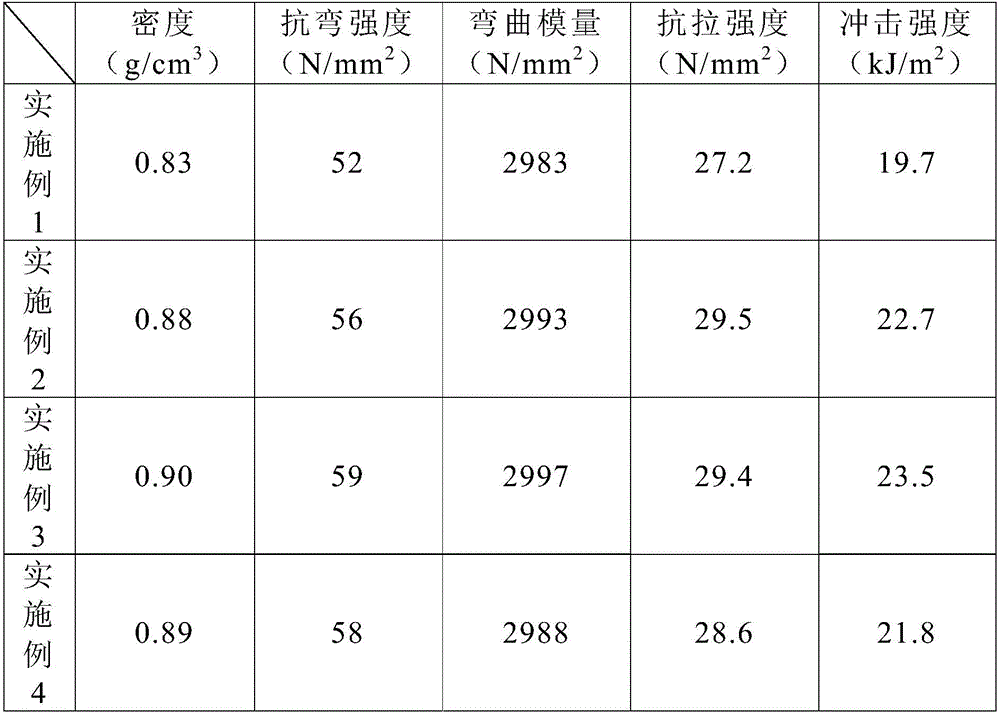

[0028] Example 1:

[0029] Take wood fiber with a diameter of 0.03 mm and a length-to-diameter ratio of 150:1 to mix evenly with polypropylene fiber to obtain a mixed fiber raw material, where wood fiber accounts for 60% of the mixed fiber raw material, and polypropylene fiber accounts for 60% of the mixed fiber raw material. Is 40%. Then, acrylic resin binder is added to the mixed fiber raw material, mixed evenly, and pressed at a high temperature of 280° C. with an 800-ton press to form a fiber mat material. The mass percentage of fibers in the fiber mat material is 80%, and the mass percentage of binder is 20%.

Example Embodiment

[0030] Example 2:

[0031] Take wood fiber and polypropylene fiber with a diameter of 0.03 mm and a length-to-diameter ratio of 150:1. The surface of the wood fiber is wrapped with an acrylic resin binder, and then the two fibers are uniformly mixed to obtain a mixed fiber raw material, of which wood fiber accounts for the mixed fiber raw material The mass percentage of polypropylene fiber is 70%, and the mass percentage of the mixed fiber raw material is 30%. Then, acrylic resin binder is added to the mixed fiber raw material, mixed evenly, and pressed at a high temperature of 280° C. with an 800-ton press to form a fiber mat material. The mass percentage of fibers in the fiber mat material is 80%, and the mass percentage of binder is 20%.

Example Embodiment

[0032] Example 3:

[0033] Take wood fiber and polypropylene fiber with a diameter of 0.03 mm and a length-to-diameter ratio of 150:1. The surface of the wood fiber is wrapped with an acrylic resin binder, and then the two fibers are uniformly mixed to obtain a mixed fiber raw material, of which wood fiber accounts for the mixed fiber raw material The mass percentage of polypropylene fiber is 80%, and the mass percentage of the mixed fiber raw material is 20%. Then, acrylic resin binder is added to the mixed fiber raw material, mixed evenly, and pressed at a high temperature of 280° C. with an 800-ton press to form a fiber mat material. The mass percentage of fibers in the fiber mat material is 85%, and the mass percentage of binder is 15%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com