Cleaning and sieving device of maize harvester and maize harvester with the same

A corn harvester and cleaning device technology, applied in the field of cleaning machines, can solve the problems of clogging the screen holes of a vibrating screen, affecting work efficiency, poor cleaning effect, etc., to prevent clogging, reduce operating costs, and improve conveying capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

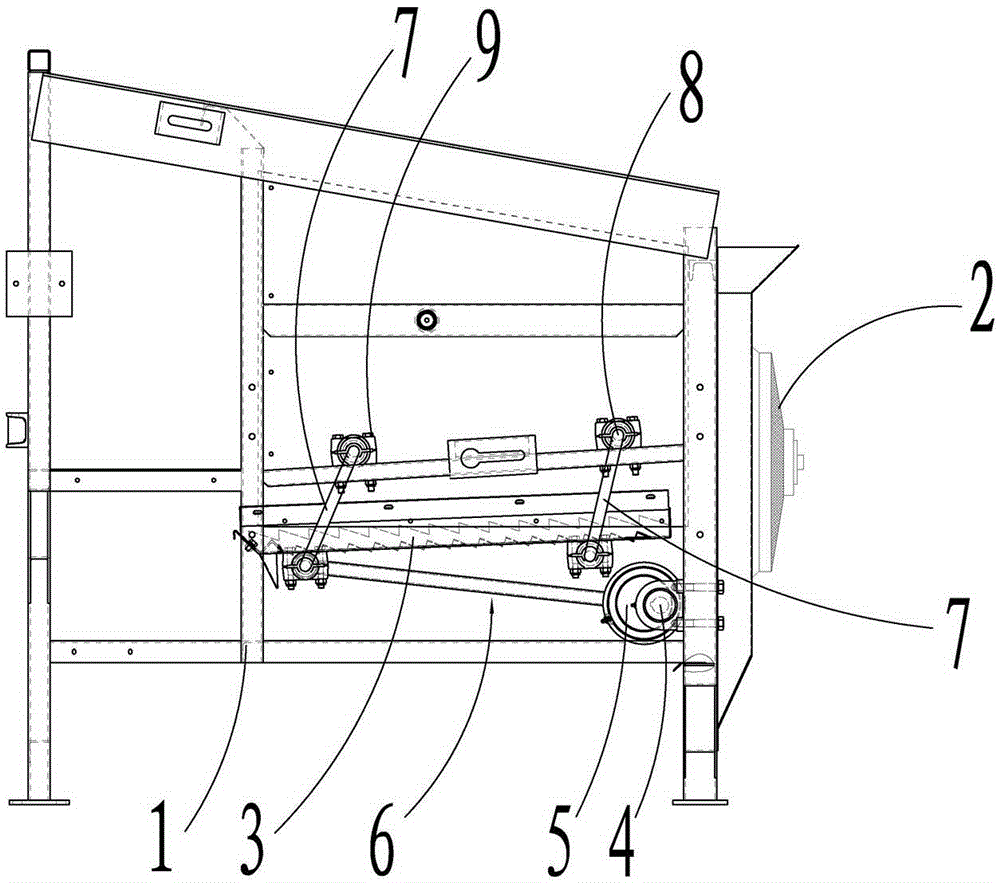

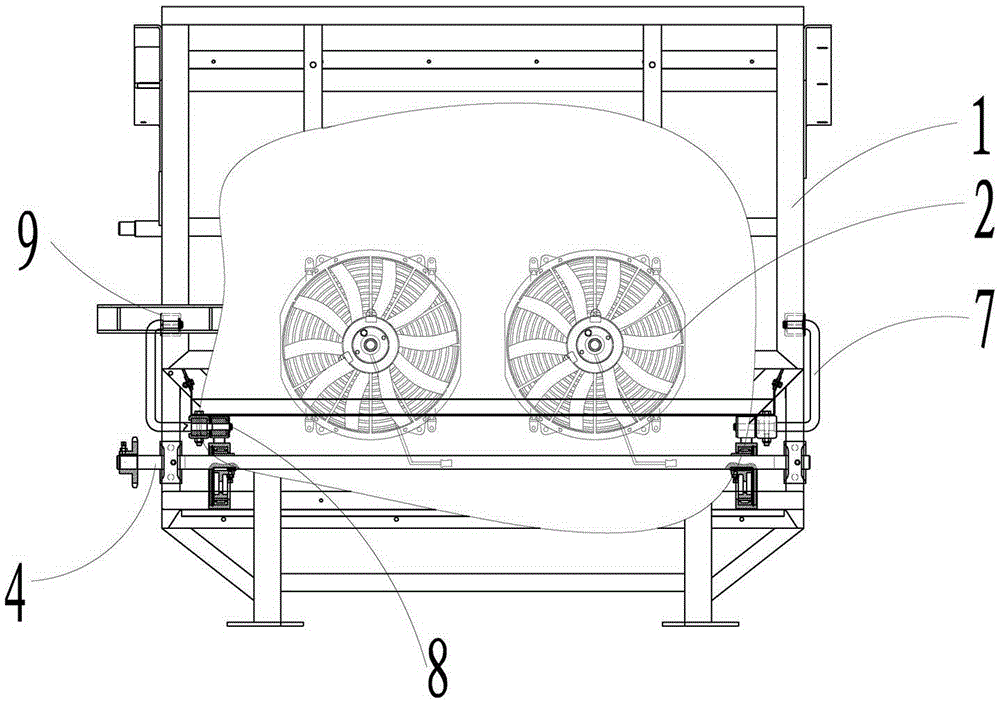

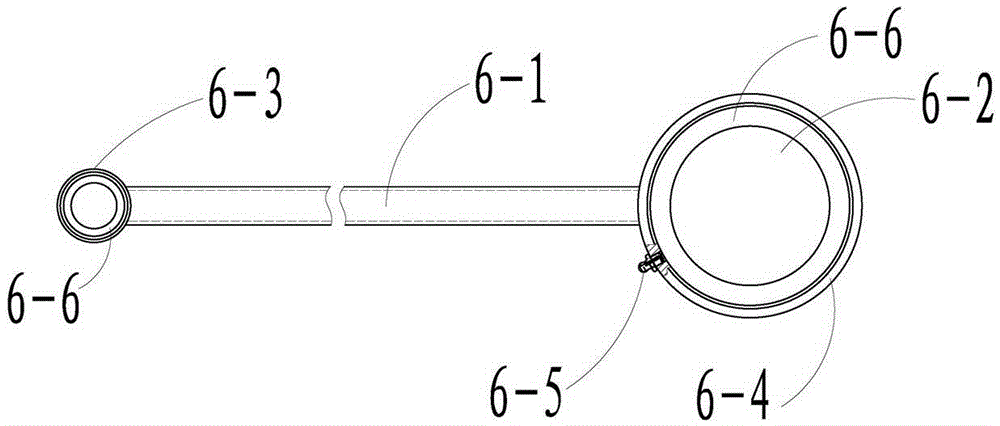

[0039] combine Figure 1~5 Shown, a kind of cleaning device for corn harvester, it comprises frame 1, blower fan 2, sieve box 3 and the hoisting type link mechanism that is used to connect frame 1 and sieve box 3; Described link mechanism includes setting The first link mechanism and the second link mechanism at the front and rear of the screen box; the bottom of the frame 1 is provided with an input shaft 4 that is rotatably connected to it; the input shaft 4 is provided with an eccentric block 5; The eccentric block 5 is covered with a middle link 6; the other end of the middle link 6 is rotatably connected to the first linkage mechanism; the fan 2 is located at one side of the screen box 3 and fixedly connected with the frame 1.

[0040] The fan 2 is located at the rear of the screen box 3 . The number of the fans 2 is two, and they are arranged in parallel.

[0041] When the cleaning device is working, the fan 2 will blow the objects to be screened that fall on the vibra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com