A controllable method for installing alumina grinding media for ball mills

A technology of grinding media and alumina, applied in grain processing and other directions, can solve the problems of high driving power of ball mill, large quality of metal grinding body and high operating current.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Below in conjunction with embodiment, further illustrate the present invention.

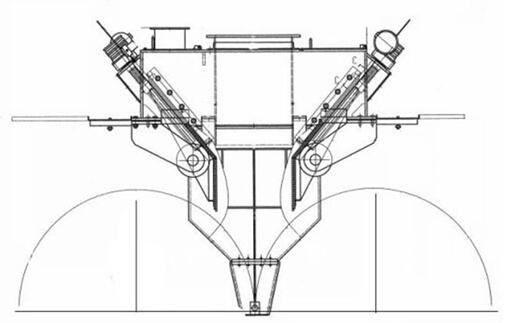

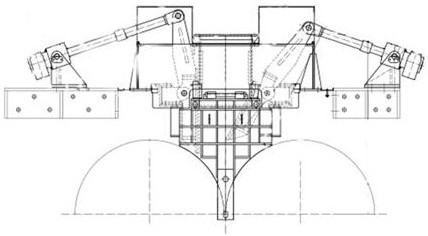

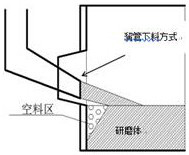

[0040] see Figure 1-7 It can be seen that a controllable method for installing alumina grinding media for a ball mill of the present invention includes the selection of alumina grinding media, the selection and technical improvement of the ball mill, the gradation of alumina grinding media and the adjustment of the central control operation method, wherein:

[0041] (1) Selection of alumina grinding medium: the grinding medium is required to be corundum ceramic material, which has the following physical and chemical indicators: bulk density ≥ 3.65 g / cm³, bulk density ≥ 2.2t / m, Mohs hardness > 9, Rockwell The hardness is 83-88, and the breakage rate is ≤0.3%; the molding method of corundum ceramic material is isostatic pressing or spinning forming, which has a high density of the green body, and the pressing method is ≤0.3%; the quality of the alumina grinding medium of the same volume is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

| Rockwell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com