Circumferential direction sewing mechanism

A sewing and hoop technology, applied in sewing equipment, textiles and papermaking, etc., can solve the problems of lower product quality, difficulty in ensuring product quality, and difficult sewing, etc., and achieve the effect of reducing work burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

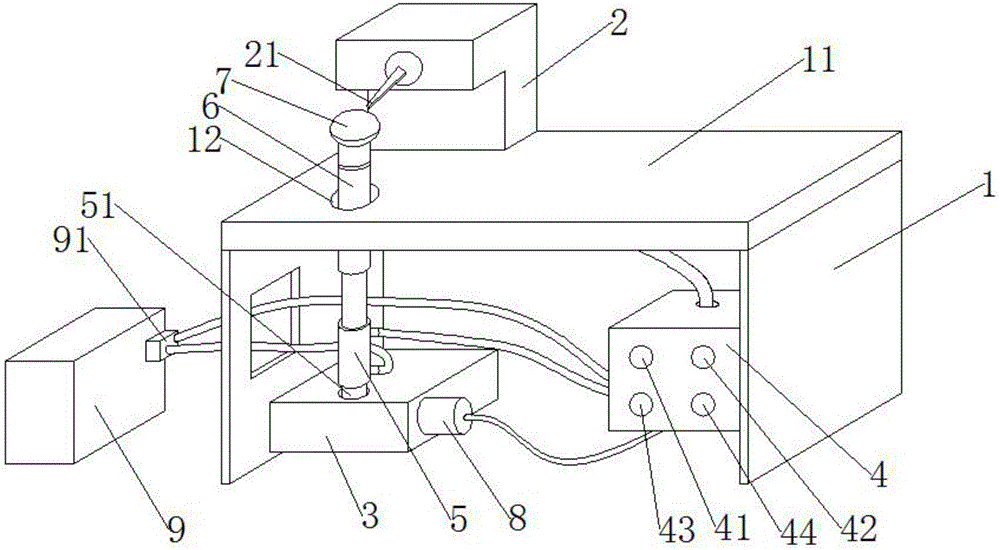

[0023] In order to make the technical means, creative features, objectives and effects of the present invention easy to understand, the following embodiments are combined with Figure 2 to 4 The vertical impact testing machine provided by the present invention is specifically explained.

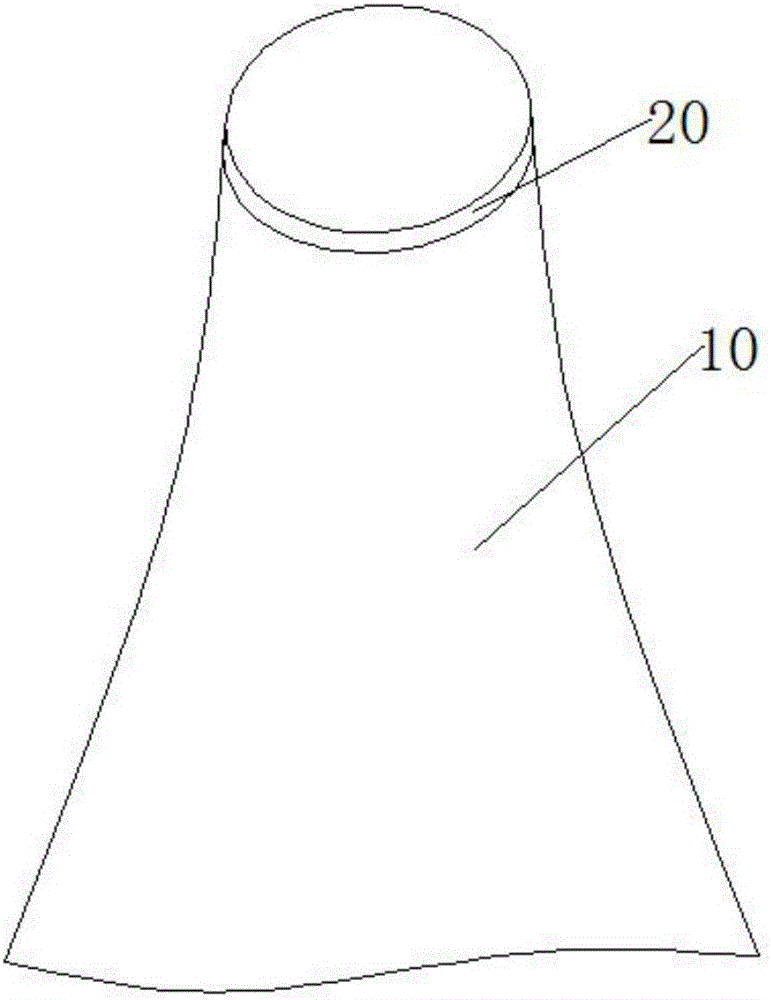

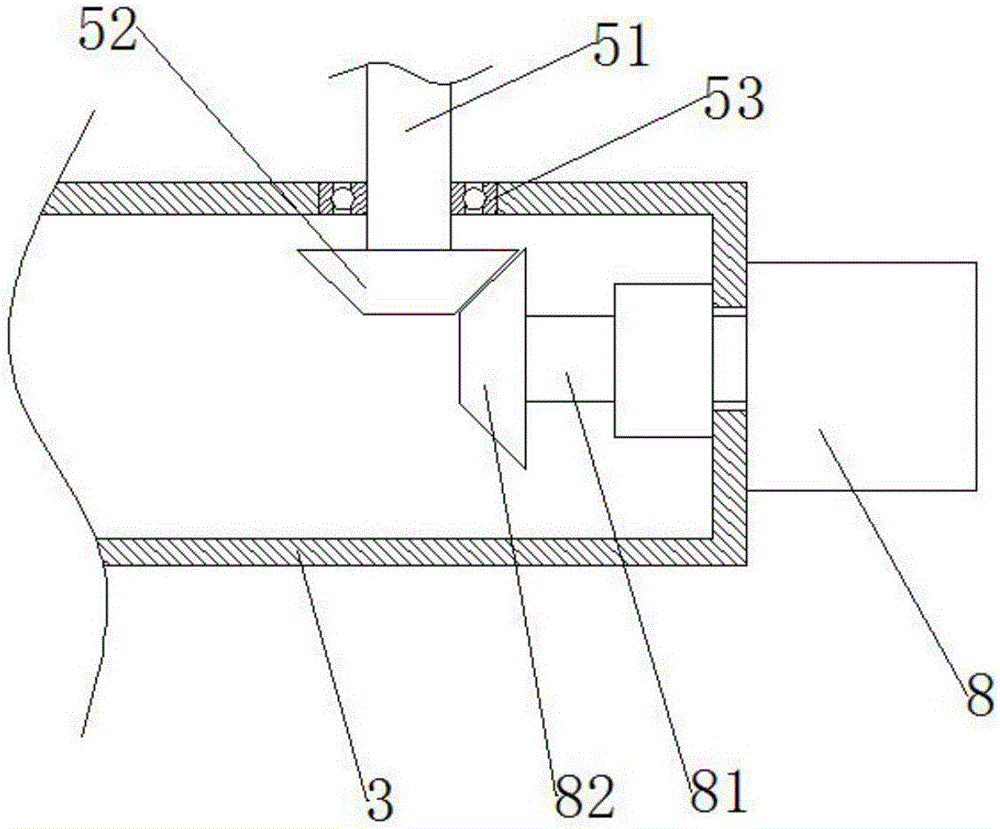

[0024] Refer to figure 2 , Is a structural schematic diagram of an embodiment of a hoop sewing mechanism, combined image 3 , Is a schematic diagram of the internal structure of the transmission box in an embodiment of the hoop sewing mechanism. Such as figure 2 with image 3 As shown in the figure, the hoop sewing mechanism provided by the present invention includes: a workbench 1, a work plane 11 is formed on the workbench 1, and a through slot 12 is formed longitudinally through the work plane 11; a lifting rod 5, which can move longitudinally through It is set in the through groove 12, and the upper end of the lifting rod 5 is formed with a storage table 7 in a cylindrical structure or a t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com