Plastic-component explosion-proof pressure-relief balancing valve quick to mount

A technology for explosion-proof valves and plastic parts, which is applied in the direction of balance valves, safety valves, valve devices, etc., which can solve problems such as complicated processing procedures, reduced manual installation efficiency, and difficult installation and selection, and achieves excellent protection performance and air tightness. Good, low-cost results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to enable those skilled in the art to better understand the technical solution of the present invention, the product of the present invention will be further described in detail below in conjunction with the embodiments and accompanying drawings.

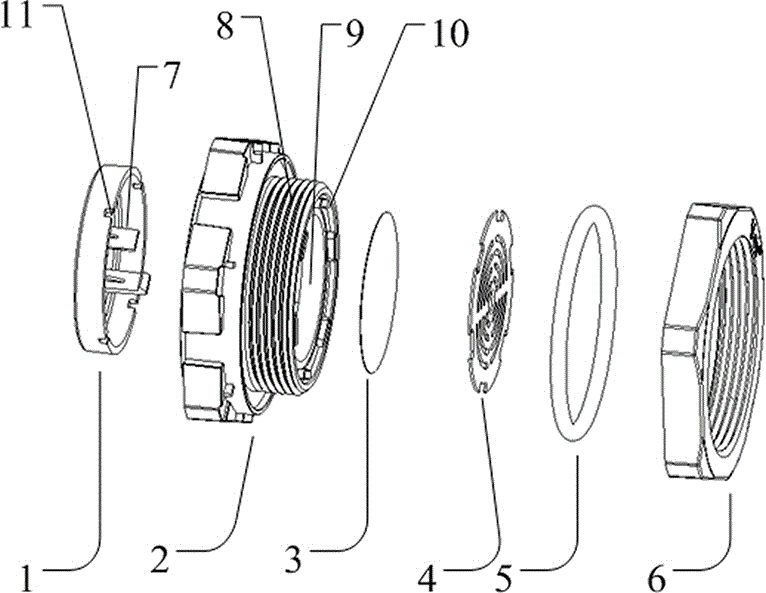

[0020] Such as figure 1 As shown, the present invention discloses a quick-install explosion-proof and pressure-relief balance valve for plastic parts, which includes an explosion-proof valve main body 2, and the inside of the explosion-proof valve main body 2 is provided with a straight-through air hole 9, and one end of the explosion-proof valve main body 2 is engaged Connected with a protective cover 1, the inside of the protective cover 1 is provided with a ventilating straight-through groove 7, and the other end of the explosion-proof valve body 2 is connected with a plastic nut 6 through a sealing ring 5, and the explosion-proof valve body 2 is connected to the plastic nut 6. The threaded connection 8 of the pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com