Novel camera rapid disassembling and assembling device

A camera and fast technology, applied in mechanical equipment, cameras, camera bodies, etc., can solve the problem that the camera quick release plate cannot be used universally, and achieve the effect of saving processing and assembly costs, and facilitating camera installation and assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

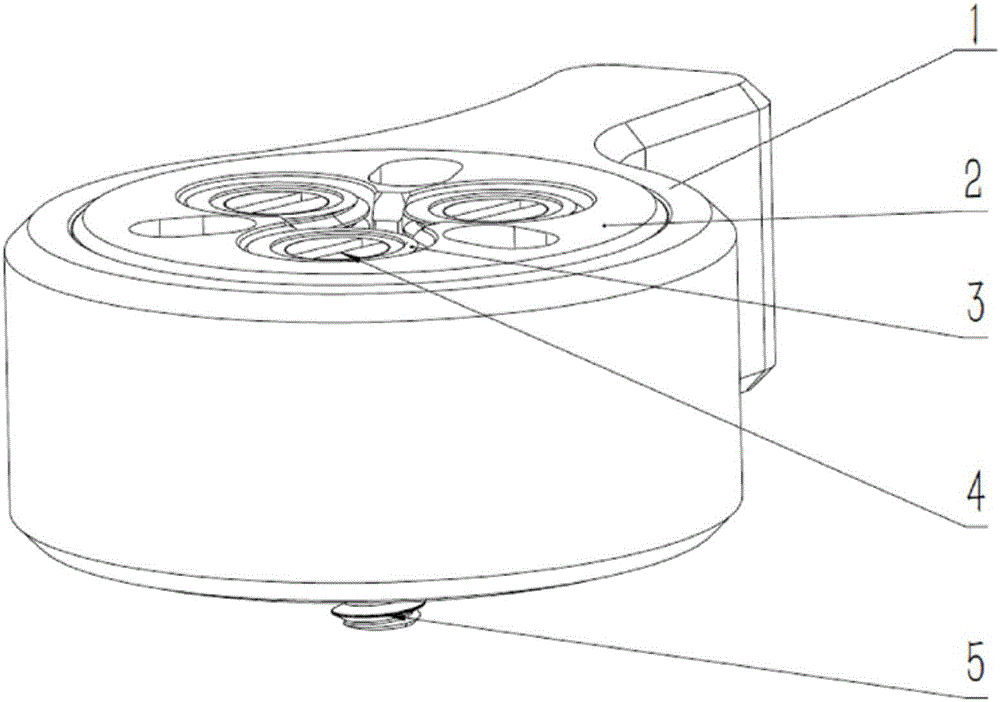

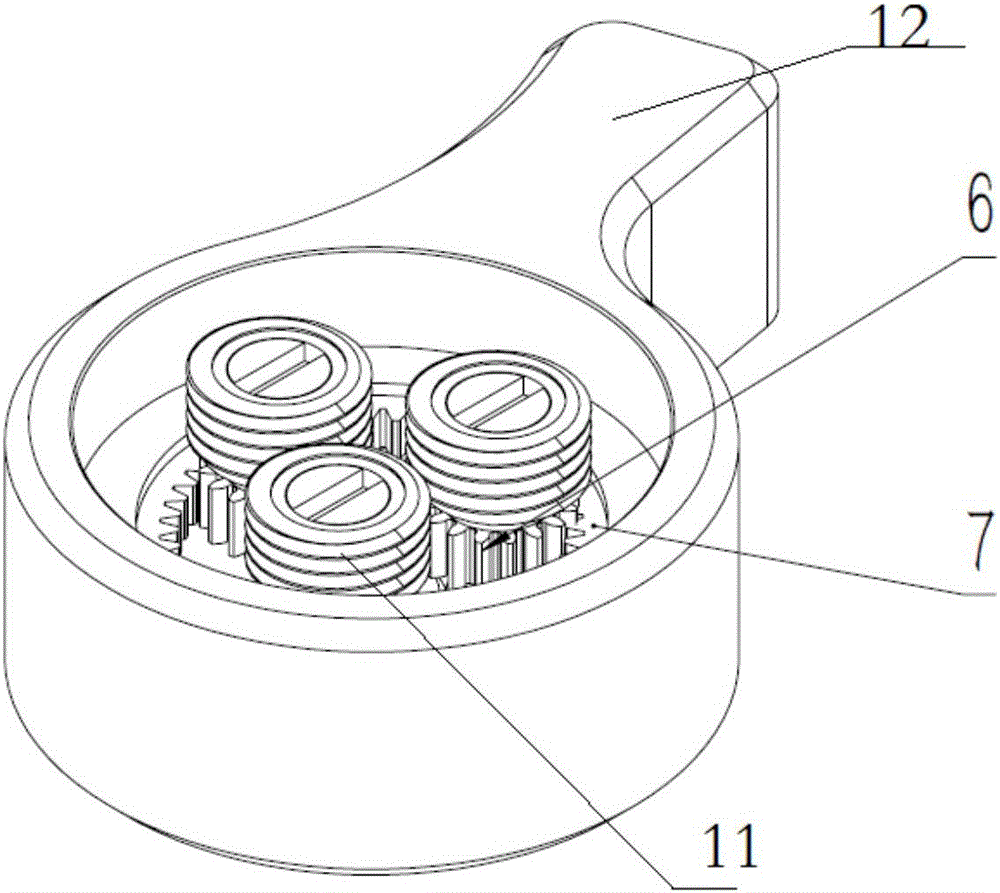

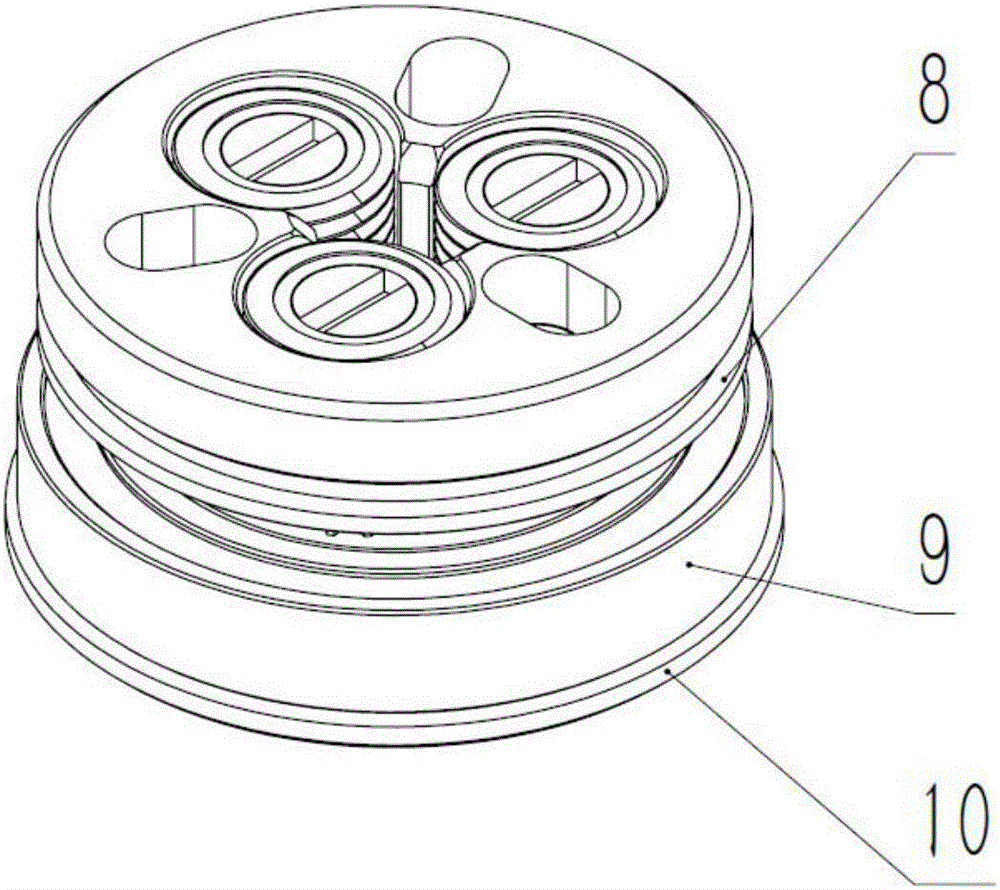

[0044] Such as Figure 1-3 As shown, in this embodiment, a new type of camera quick disassembly equipment is provided, which includes a main body 1, a lower cover 10 and a gear set 3; the main body 1 is hollow, and the main body 1 The lower end is rotatably connected with the lower cover 10;

[0045] The gear set 3 is rotatably connected with the lower cover 10; the inner wall of the main body 1 is provided with a ring gear 7; the gear set 3 includes at least three gears 6 meshing with the ring gear 7; at least three The two gears 6 are evenly distributed around the central axis of the ring gear 7;

[0046] A threaded column 11 is fixed above each gear 6, and the threaded column 11 is arranged coaxially with the gear 6; at least three of the threaded columns 11 form a hole for the camera to move up and down. ; The thread direction, diameter, and height of each threaded column 11 are the same. The center lines of all threaded posts are on the same circle. The center of these threa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com