Resin sand sampling machine

A technology of sample making machine and resin sand, which is applied in sampling, preparation of test samples, measuring devices, etc., can solve problems such as not being able to meet requirements well, and achieve the effects of simple structure, convenient operation and less maintenance work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, where the schematic embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

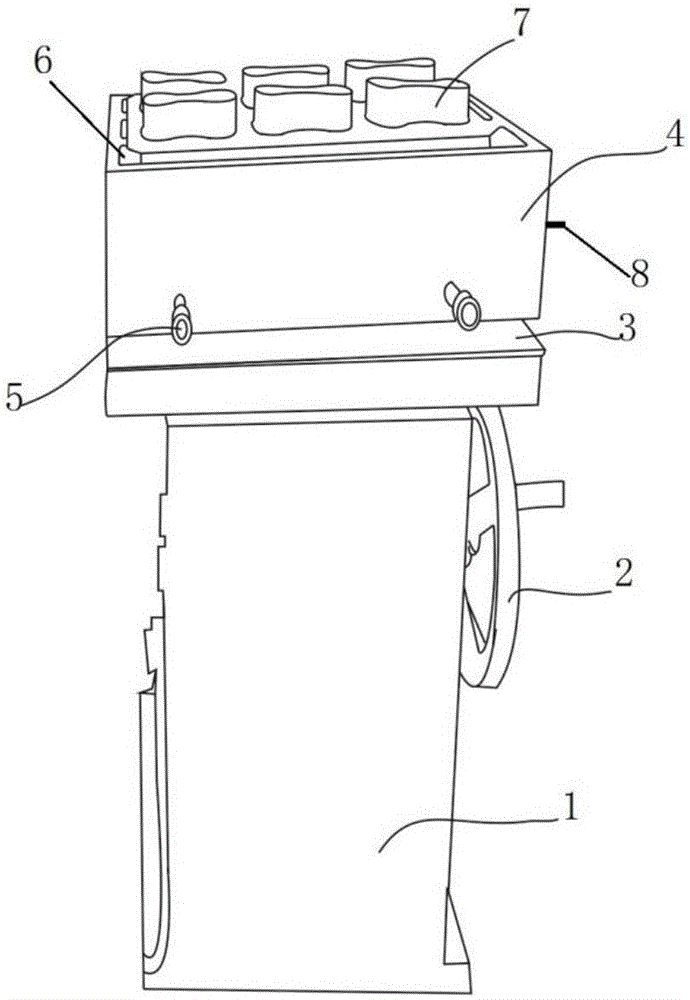

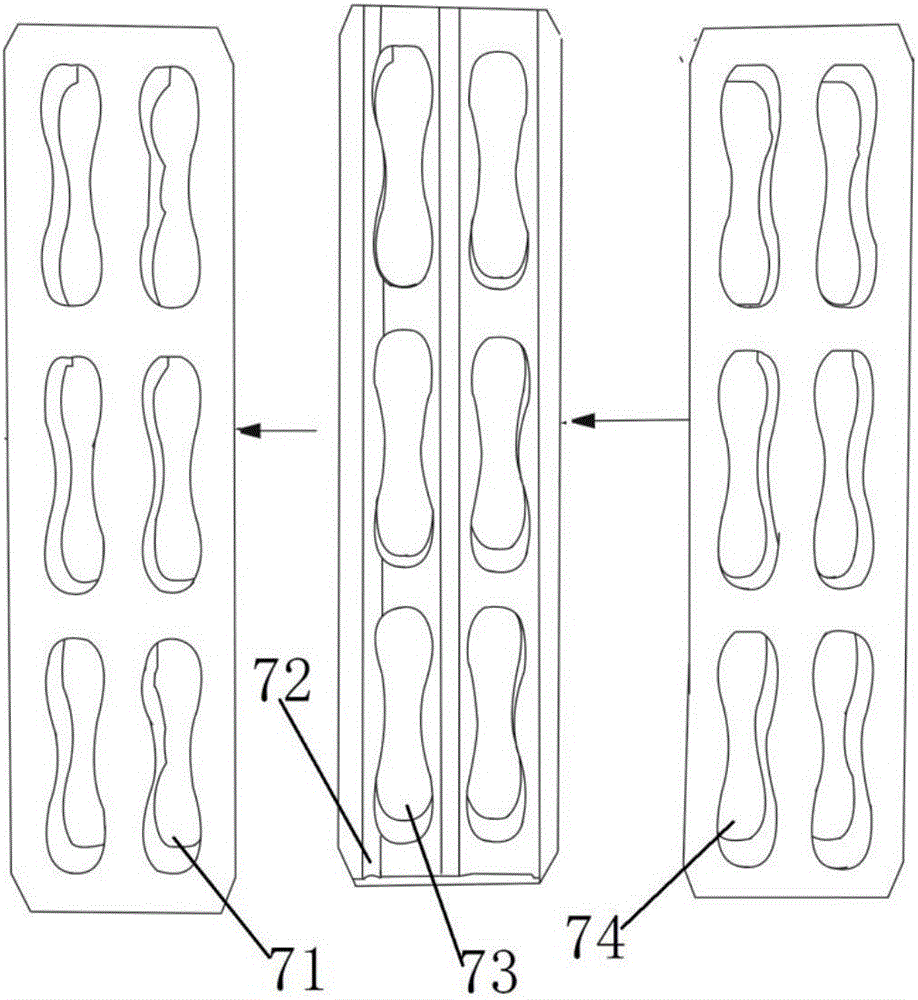

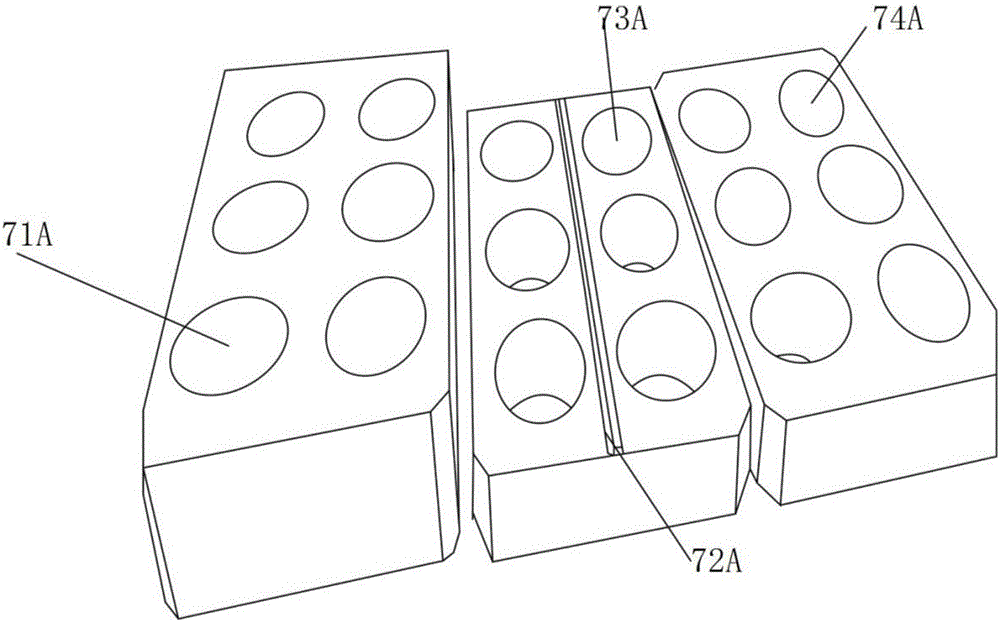

[0015] refer to Figure 1 to Figure 3 , the invention discloses a resin sand prototyping machine, comprising a host 1, the host 1 is provided with a jarring handwheel 2, and the jarring handwheel 2 is connected with a jarring mechanism, and the jarring mechanism is arranged on the side of the host 1 Inside, the main machine 1 is provided with an operation platform, a backing plate 3 is arranged above the operation platform, a pre-filling frame 4 is arranged above the backing plate 3, and a sample mold is fixed on the pre-filling frame 4. Screw 5 and sample broach 8, wherein, described pre-filled frame 4 is provided with sample module 7, and described sample module 7 is a figure-of-eight m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com