VA all-perspective LCD and manufacturing method thereof

An LCD display, full viewing angle technology, used in instruments, nonlinear optics, optics, etc., can solve the problem that VA type LCD displays cannot meet the requirements of customers' display viewing angle range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

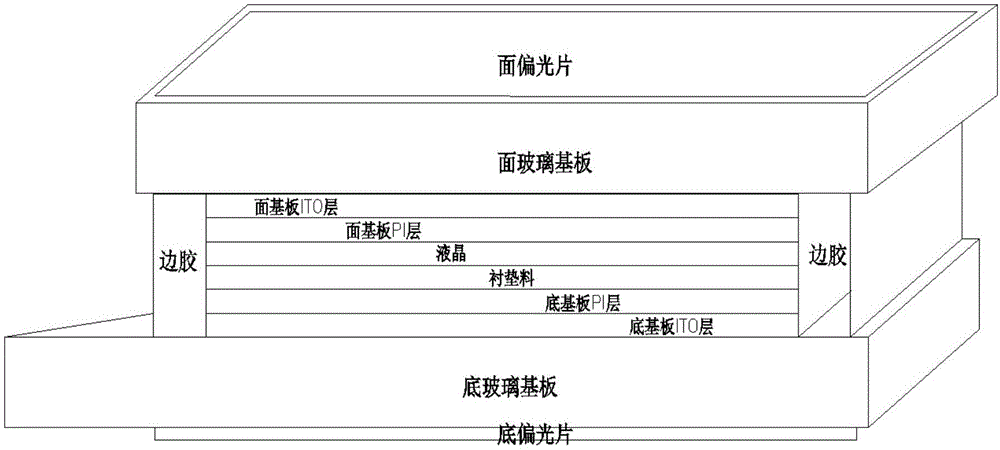

[0024] A VA full viewing angle LCD display, such as figure 1 As shown, it includes a plane polarizer, a plane glass substrate, a plane substrate ITO layer, a plane substrate PI alignment layer, a liquid crystal layer, spacers, a bottom substrate PI alignment layer, a bottom substrate ITO layer, and a bottom substrate stacked from top to bottom. Glass substrate and bottom polarizer, and edge glue for sealing surface substrate PI alignment layer, liquid crystal layer, and bottom substrate PI alignment layer.

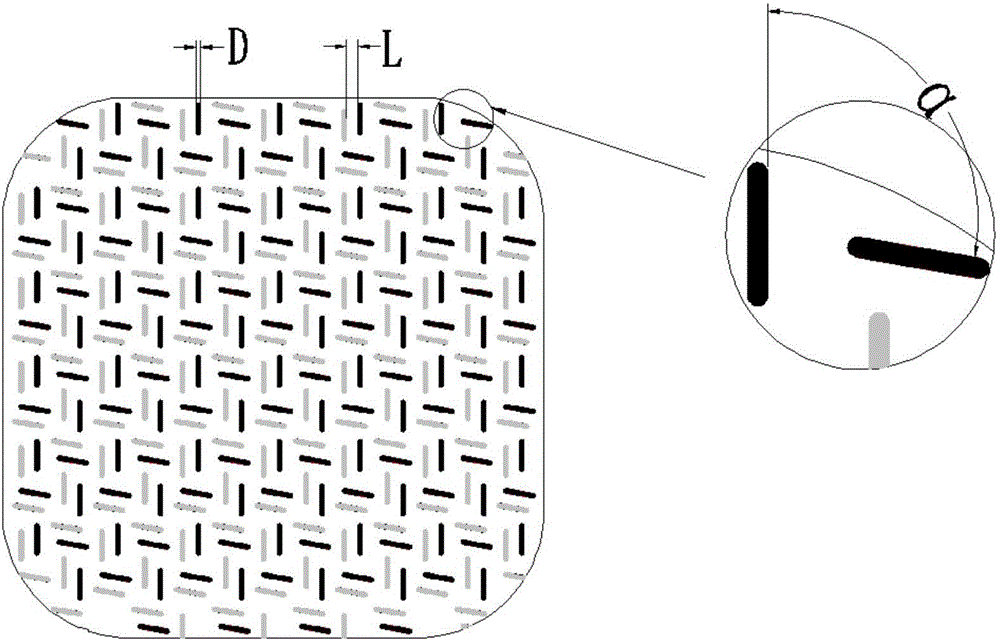

[0025] In order to expand the display viewing angle range of the LCD display, the same pixel on the ITO layer of the surface substrate and the ITO layer of the bottom substrate of the present invention is divided by a plurality of evenly distributed thin strip-shaped hollow strips. see figure 2 . That is, each pixel of the ITO layer of the surface substrate and the ITO layer of the bottom substrate is provided with several thin strip-shaped hollow strips. The hollow st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com