Electric equipment maintenance test grounding mechanical locking device

A technology of mechanical locking and power equipment, applied in the direction of substation grounding layout, switchgear, electrical components, etc., can solve the problem of long connection distance of grounding wires, out of sight range, non-compliance with maintenance test grounding controllable, under control, under control and other issues to achieve the effect of compact structure, preventing loosening, preventing accidental touch or misoperation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

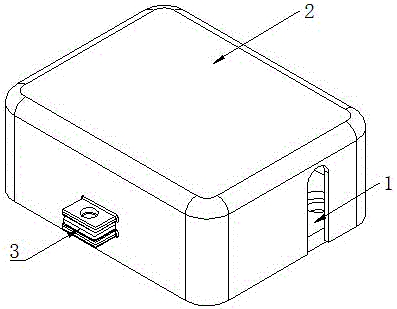

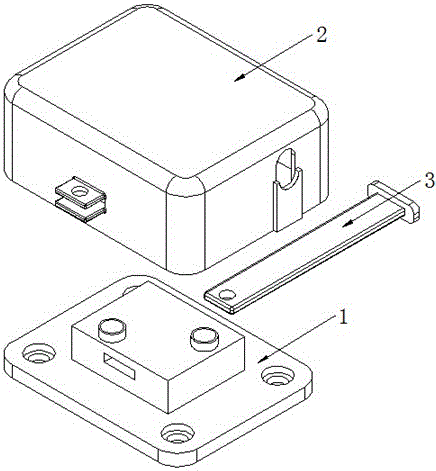

[0034] A grounding mechanical locking device for power equipment maintenance test in this embodiment, such as figure 1 , figure 2 As shown, it is mainly realized through the following technical solutions: a grounding mechanical locking device for power equipment maintenance and testing, including a grounding support 1 fixed on the grounding flat iron of the substation, an insulating protective shell 2 and a lock with a lock hole 31 Strip 3, the insulating protective shell 2 is covered above the grounding support 1 and is fixedly connected to the grounding support 1 through the locking bar 3; the grounding support 1 is provided with a ground threaded hole 11 for fixing the ground wire connector and connecting Slot 12; the insulating protective shell 2 is provided with a lock 21, a lock bar channel 22 and a grounding wire channel 23, and the lock bar 21 is located at the opening end of the lock bar channel 22; the lock bar 3 passes through the connecting groove 12, the lock bar...

Embodiment 2

[0036] This embodiment is further optimized on the basis of the above-mentioned embodiments. Further, the connecting groove 12 is a through groove that runs through the grounding support 1, and the locking strip channels 22 are correspondingly arranged at both ends of the connecting groove 12, and the locking strips 3 are respectively penetrated. Connect the slot 12 and the locking bar channel 22 . Other parts of this embodiment are the same as those of the foregoing embodiments, so details are not repeated here.

Embodiment 3

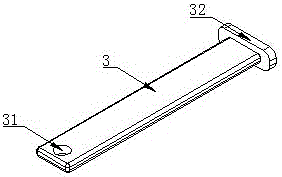

[0038] This embodiment is further optimized on the basis of the above embodiments, further, as image 3 As shown, the lock bar 3 is generally in the shape of a slat, with a positioning plate 32 disposed at one end and at least one lock hole 31 disposed at the other end. Other parts of this embodiment are the same as those of the foregoing embodiments, so details are not repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com