Complete set of lead wire leading device for 10-kV transformer area and manufacturing method thereof

A transformer and station area technology, applied in the direction of line/collector parts, cable joints, electrical components, etc., can solve the problem that no one has developed 10KV cable pre-branching, and achieve the effect of reducing on-site installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the examples, but the protection scope of the present invention is not limited only to the examples.

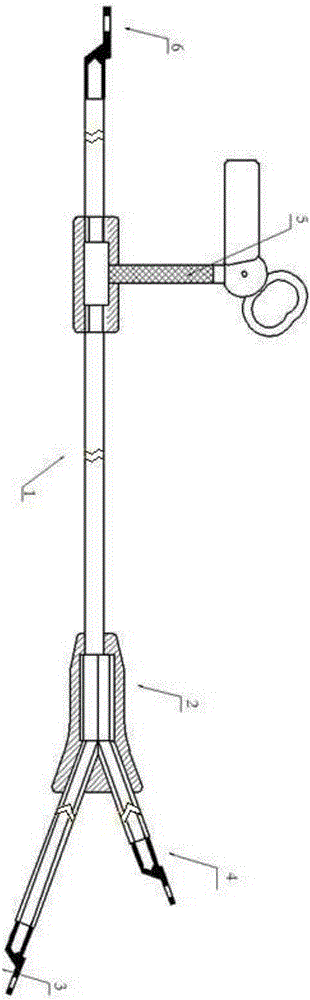

[0018] combine figure 1 Shown, a kind of 10KV transformer platform area complete set lead wire device has trunk cable 1, is connected with the first pre-branch cable 2 on the described trunk cable 1, the end of the first pre-branch cable 2 ( figure 1 The upper end) is provided with a connecting terminal 3 for connecting the arrester. One end of the backbone cable 1 is provided with a connecting device terminal 4, and the other end is connected with a connecting wire terminal 6 or an isolating switch terminal, and the connecting device terminal 4 is arranged on the backbone cable 1 close to the lightning arrester One end of terminal 3 ( figure 1 The upper end of the connecting wire terminal 6 or the isolating switch terminal is located at the end of the main cable 1 away from the arrester termin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com