A charger control system and method

A control system and control method technology, applied in charging stations, circuit monitoring/indication, different battery charging, etc., can solve problems such as difficulty in satisfying non-linear change adjustment, inability to check immediately for maintenance, inability to see real-time waveforms, etc. , to achieve the effect of improving safe operation, accurate fault record and analysis, and improving convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

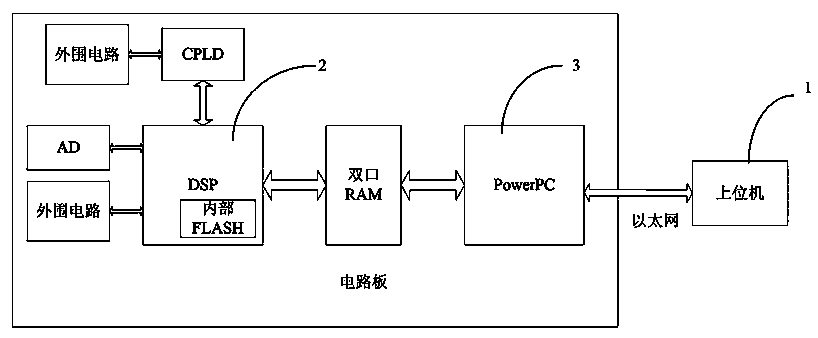

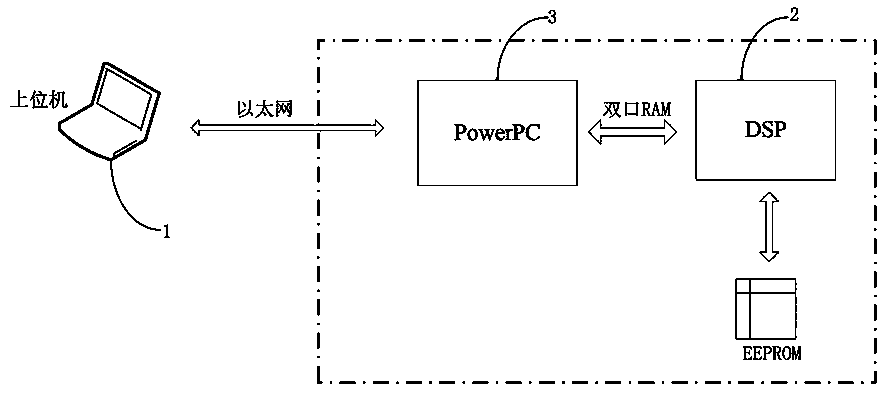

[0035] Such as figure 1 As shown, the charger control system of this embodiment includes a DSP unit 2, a PowerPC unit 3 and a host computer 1, and the DSP unit 2 and the PowerPC unit 3 communicate with each other through a dual-port RAM unit; the host computer 1 and the PowerPC unit 3 They are connected through Ethernet communication for remote real-time monitoring and maintenance of the charger. In the charging machine control system of the present invention, the upper computer 1 is connected to the charging machine through the Ethernet, and can remotely monitor and maintain the charging machine in real time, thereby improving the operation safety of the charging machine and improving the convenience of equipment maintenance.

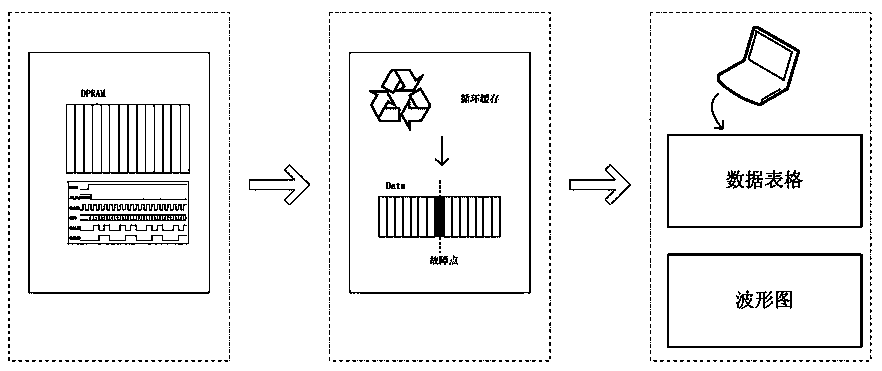

[0036] In this embodiment, the DSP unit 2 is connected with a storage unit, which is used for cyclically storing the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com