Handle body for toothbrush, its forming method and toothbrush

A toothbrush and handle body technology, applied in the direction of brush body, brush type, application, etc., can solve the problem of lack of shape diversity and achieve the effect of rich shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach >

[0035] A toothbrush according to a first embodiment of the present invention will be described with reference to the drawings.

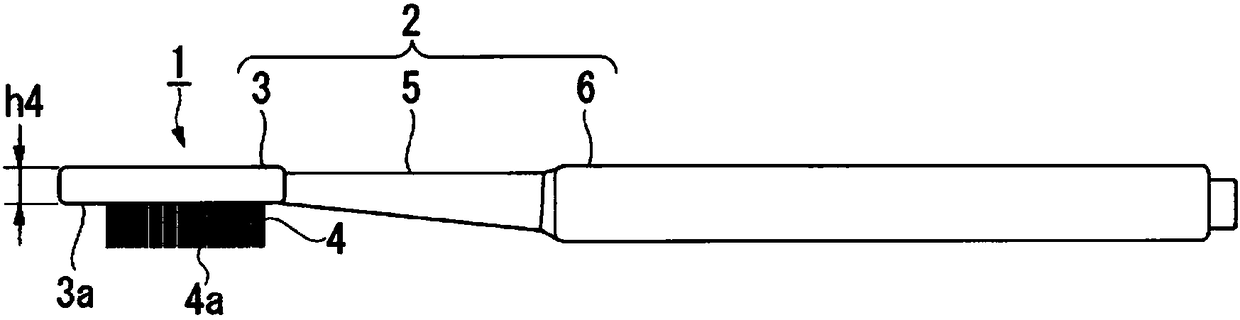

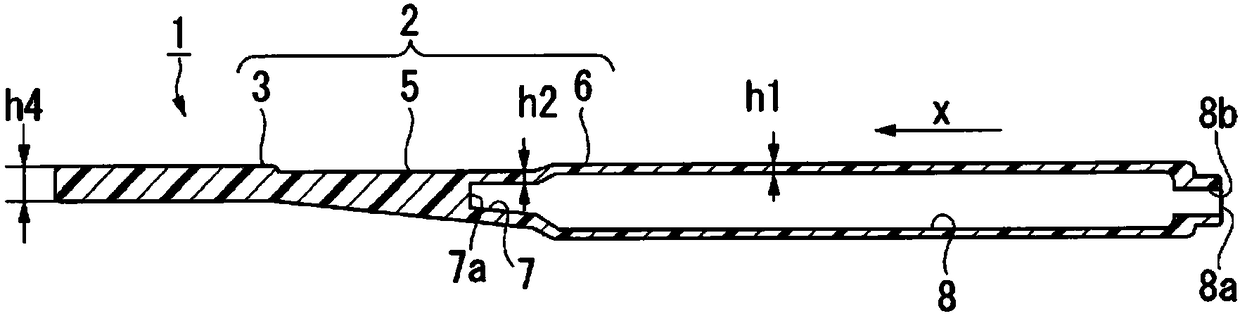

[0036] Such as Figure 1A As shown, the toothbrush 1 of the present embodiment has a handle 2 and a bristle bundle 4 embedded in the head 3 provided on the handle 2 .

[0037] The handle body 2 is integrally formed by blow molding, and includes: a head 3 , a handle 6 , and a neck 5 connecting the head 3 and the handle 6 .

[0038] and, in Figure 1A In the toothbrush 1 of the present embodiment shown, the neck portion 5 protruding from the grip portion 6 is formed thinner than the grip portion 6 . In addition, the head portion 3 protruding from the neck portion 5 is formed to be slightly larger than the dimension in the thickness direction of the tip portion of the neck portion 5 to which the head portion 3 is connected. In addition, the shape of a toothbrush is not limited to this, For example, it can also be comprised so that a grip part and a nec...

no. 2 approach >

[0086] The second embodiment of the present invention is a modified example of the first embodiment described above, and the description of the same parts as the first embodiment will be omitted.

[0087] Such as Figure 4 As shown, the toothbrush 11 of this embodiment is provided not only with the grip portion 6 and the neck portion 5 of the handle body 2 but also with the hollow portion 13 connected to the hollow portion 7 of the neck portion 5 in the head 12 .

[0088] In this way, the hollow part 13 is also provided in the head part 12, and as a result, the change of shape is richer than 1st Embodiment.

[0089] In addition, h1≤ h2≤h3 or h2≤h1≤h3 relationship.

[0090] By making the thickness of the neck portion 5 thinner than that of the head portion 3 in this way, it is possible to obtain a toothbrush 11 that has a greater degree of deflection than conventional ones and has a softer hardness when brushing teeth.

[0091]In addition, similar to the wall thicknesses h1 ...

Embodiment

[0098] Hereinafter, the present invention will be described in more detail based on examples. However, the present invention is not limited at all by the following examples.

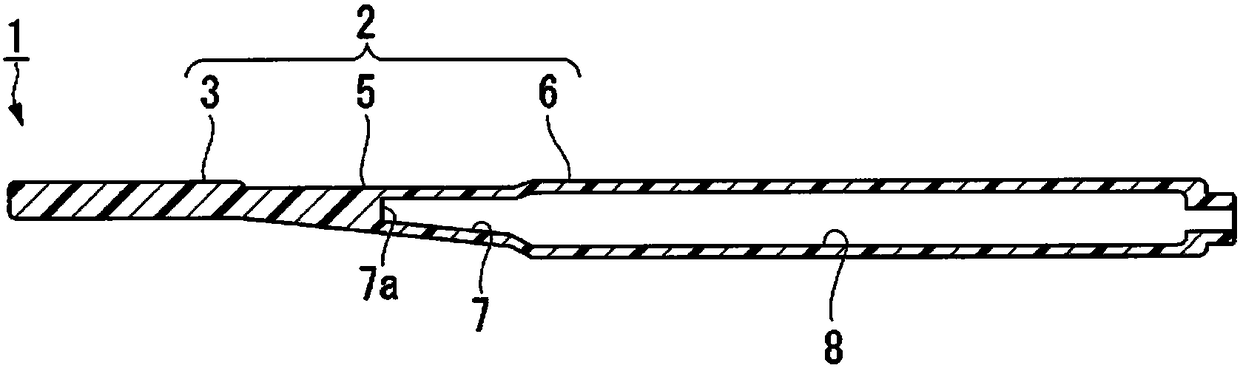

[0099] In this embodiment, as embodiment 1, prepared such as Figure 1B The toothbrush in which the top end of the hollow portion of the neck as shown is located closer to the grip portion than the center of the neck. In addition, as Example 2, prepared such as figure 2 The toothbrush in which the top end of the hollow part of the neck is located in the center of the neck as shown. And, as Example 3, prepared such as image 3 The toothbrush in which the top end of the hollow portion of the neck as shown is located closer to the head side than the center of the neck.

[0100] In addition, as Comparative Example 1, a general toothbrush (both solid head and neck) and an electric toothbrush (injection-molded toothbrush with hollow neck and handle. Among them, the head is exchangeable) were prepared. In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com