Environmentally-friendly sewage treatment mechanical grilling facility

A sewage treatment and mechanical technology, applied in water/sewage treatment, water/sludge/sewage treatment, filtration treatment, etc., can solve problems such as inability to adjust and adapt to water flow, inconvenience to prevent device damage, and insufficient flexibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

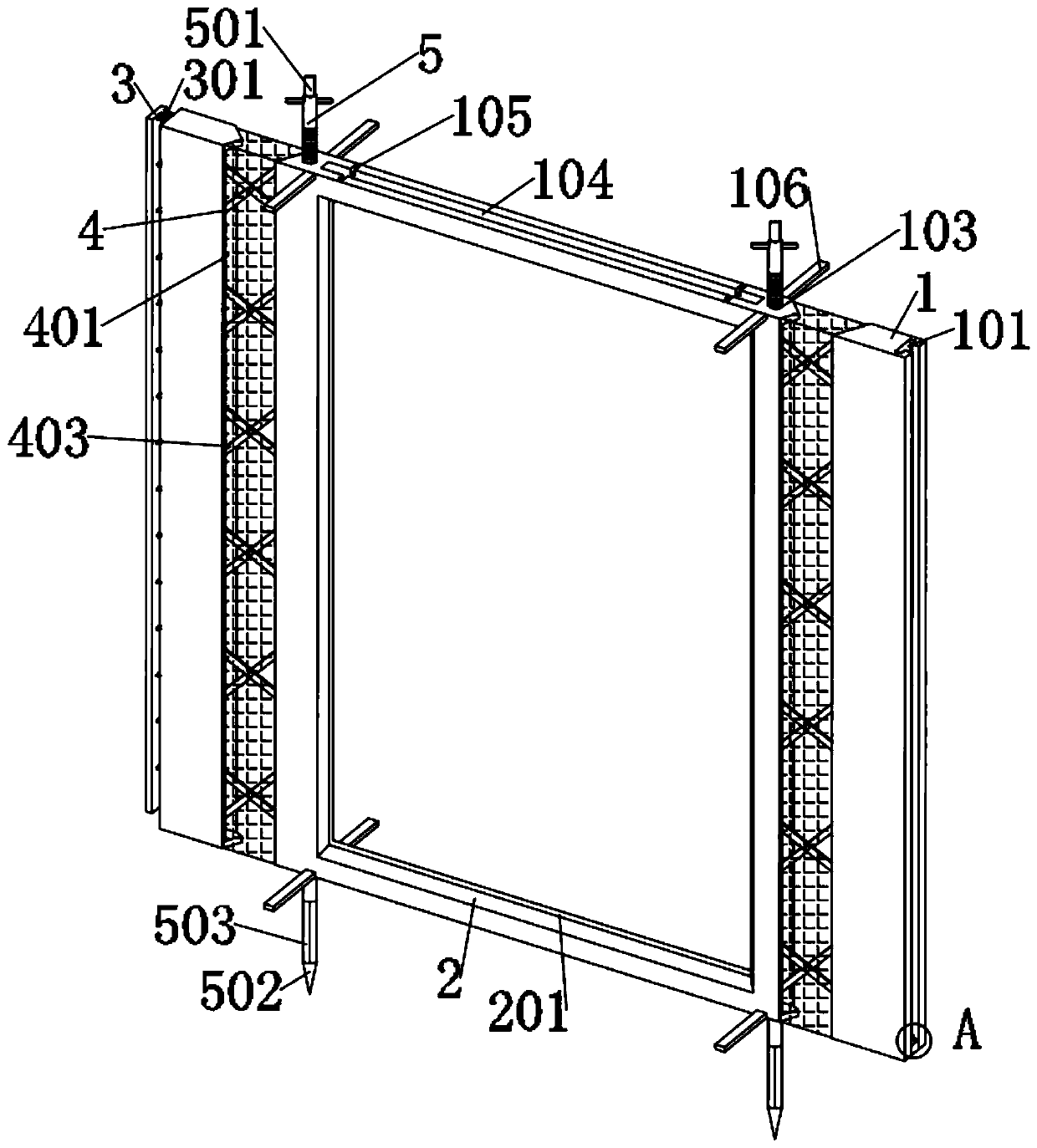

[0030] as attached figure 1 to attach Figure 8 Shown:

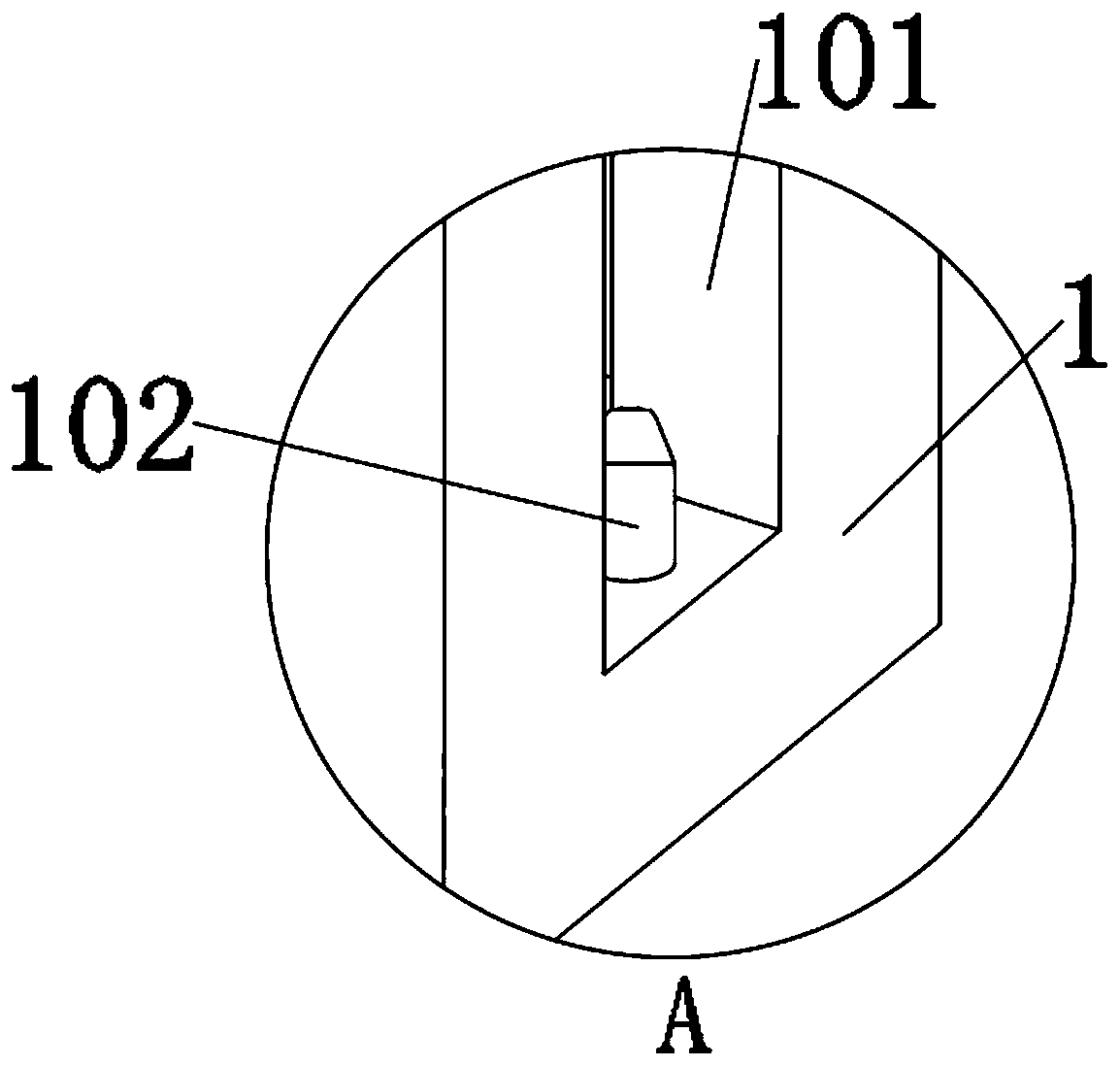

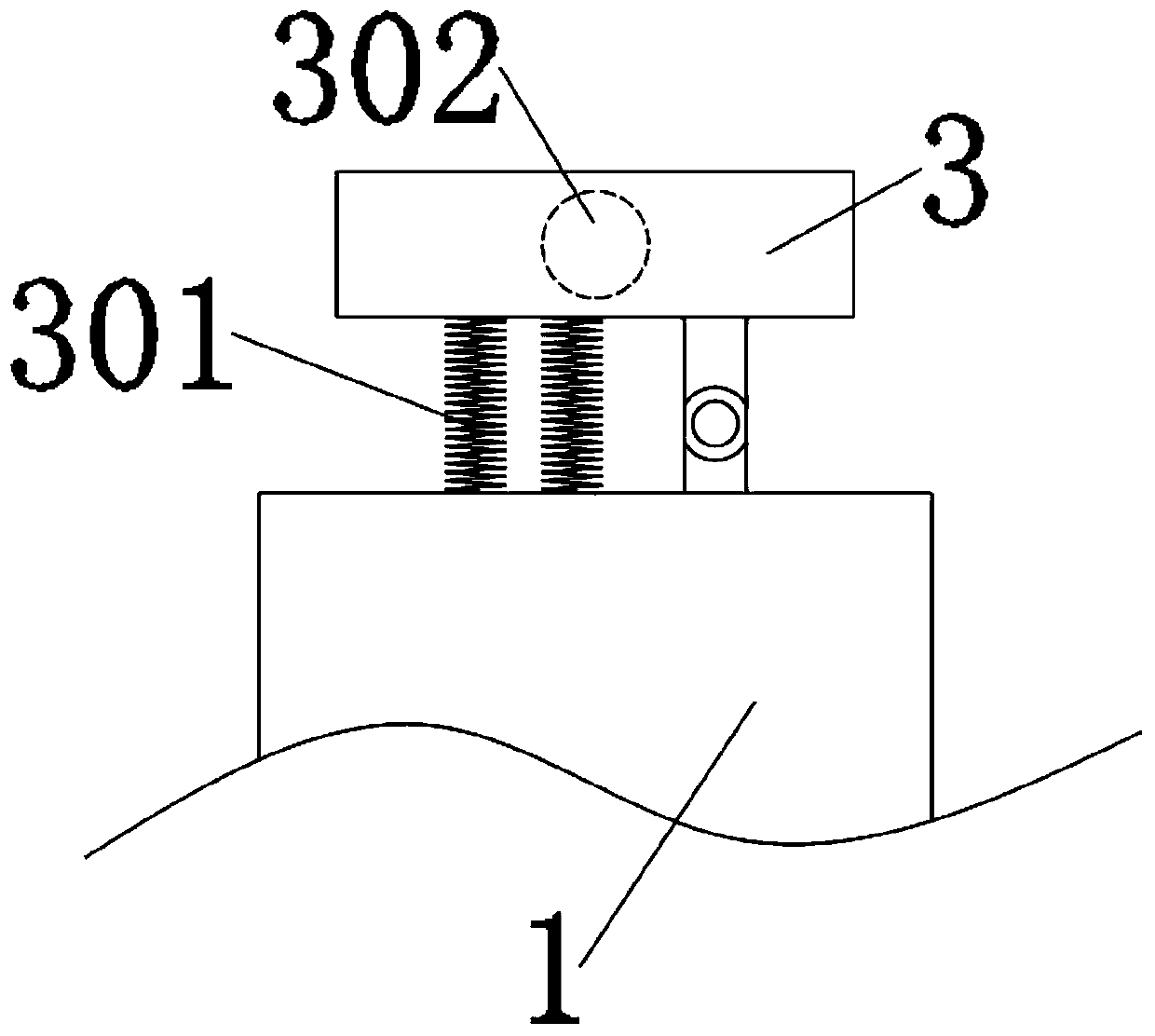

[0031]The invention provides an environment-friendly mechanical grille facility for sewage treatment, comprising: a main body 1, a connecting groove 101, a fixing rod 102, a threaded hole 103, an insertion groove 104, a stabilizing groove 105, a side plate 106, a filter port 2, an inner Embedded groove 201, embedded hole 202, connector 3, connecting spring 301, fixing hole 302, extension port 4, side groove 401, inner groove 402, cross arm 403, moving rod 5, inner rod 501, insertion head 502, flip Part 503, intercepting part 6, stabilizing head 601, intercepting net 602, connecting part 603 and embedded column 604; main body 1 is a rectangular plate-shaped structure, and a threaded hole 103 of cylindrical structure is provided at the middle position on both sides above the main body 1, And the middle position of the main body 1 is provided with a filter port 2; the right side of the connector 3 is connected to the rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com