Low-adhesiveness foam sheet

A technology of foam sheet and foam body, which is applied in the fields of foam sheet and electrical/electronic equipment, can solve problems such as difficult peeling and correction, lower yield rate, low surface adhesion, etc., and achieve excellent shock absorption, Prevent damage, thin thickness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

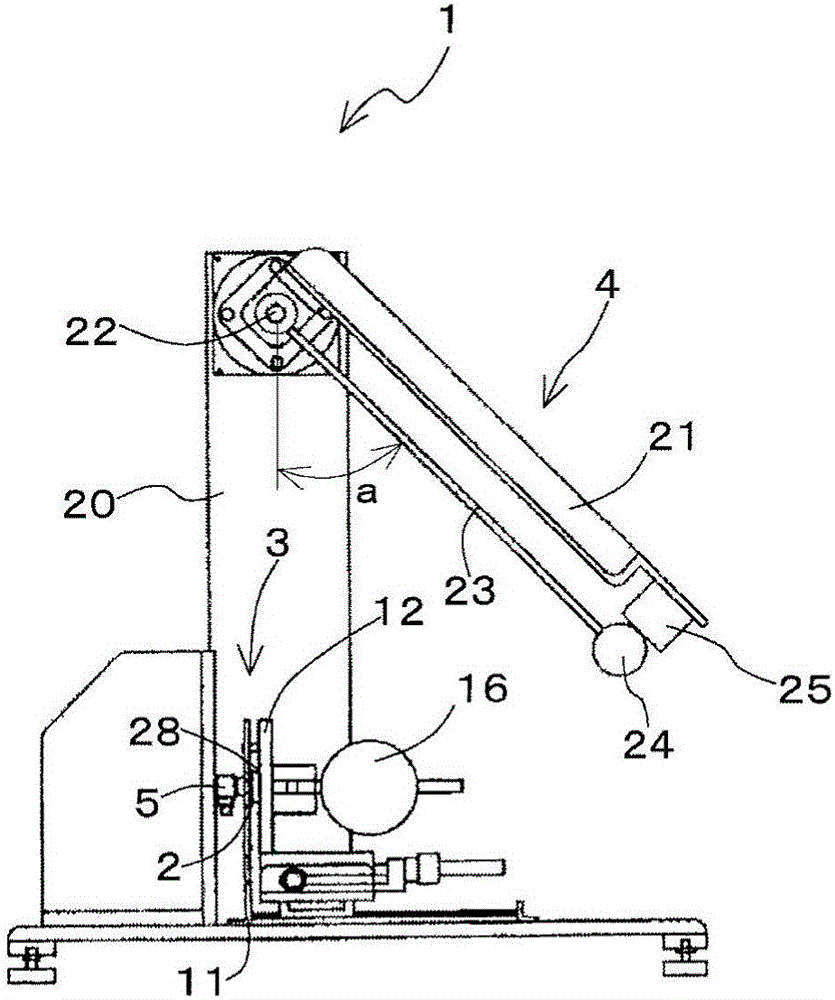

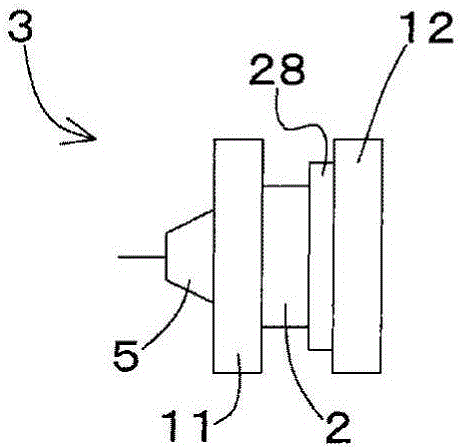

Image

Examples

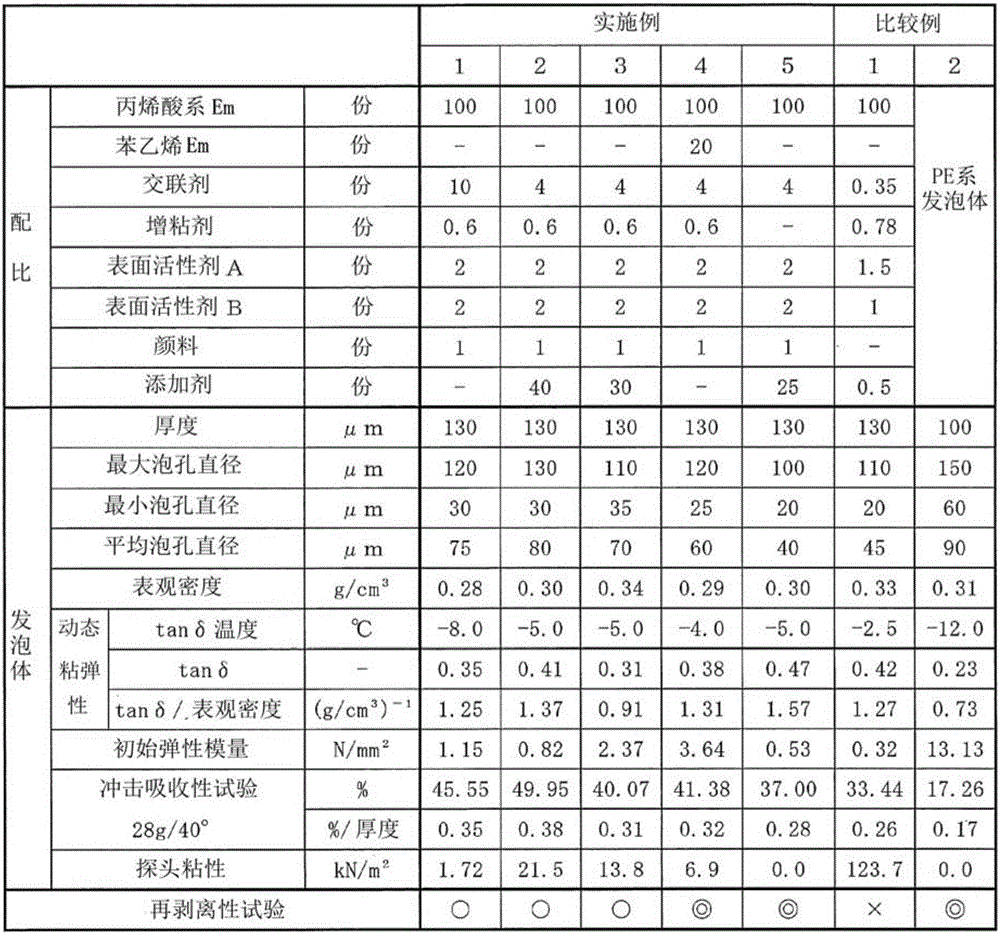

Embodiment 1

[0113] 100 parts by weight of an acrylic emulsion solution (solid content 55%, ethyl acrylate-butyl acrylate-acrylonitrile copolymer (weight ratio 45:48:7)), fatty acid Ammonium-based surfactant (aqueous dispersion of ammonium stearate, solid content 33%) (surfactant A) 2 parts by weight, carboxybetaine-type amphoteric surfactant ("Amogen CB-H", Daiichi Kogyo Pharmaceutical company) (surfactant B) 2 parts by weight, oxazoline-based crosslinking agent ("EPOCROS WS-500" manufactured by Nippon Catalyst Co., Ltd., solid content 39%) 10 parts by weight, pigment (carbon black) (" NAF-5091" (manufactured by Dainichi Seika Kogyo Co., Ltd.) 1 part by weight, polyacrylic acid thickener (ethyl acrylate-acrylic acid copolymer (acrylic acid 20% by weight), solid content 28.7%) were stirred and mixed, and of bubbling. This foaming composition was coated on a PET (polyethylene terephthalate) film (thickness: 38 μm, trade name “MRF#38” manufactured by Mitsubishi Plastics Co., Ltd.) after pee...

Embodiment 2

[0115] 100 parts by weight of an acrylic emulsion solution (solid content 55%, ethyl acrylate-butyl acrylate-acrylonitrile copolymer (weight ratio 45:48:7)), fatty acid Ammonium-based surfactant (aqueous dispersion of ammonium stearate, solid content 33%) (surfactant A) 2 parts by weight, carboxybetaine-type amphoteric surfactant ("Amogen CB-H", Daiichi Kogyo Pharmaceutical company) (surfactant B) 2 parts by weight, oxazoline-based crosslinking agent ("EPOCROS WS-500" manufactured by Nippon Catalyst Co., Ltd., solid content 39%) 4 parts by weight, pigment (carbon black) (" NAF-5091" manufactured by Dainichi Seika Kogyo Co., Ltd.) 1 part by weight, polyacrylic acid thickener (ethyl acrylate-acrylic acid copolymer (acrylic acid 20% by weight), solid content 28.7%) 0.6 part by weight, aluminum hydroxide ( 40 parts by weight of "HIGILITE H42" (manufactured by Showa Denko Co., Ltd.) were stirred and mixed to be foamed. This foaming composition was coated on a PET (polyethylene ter...

Embodiment 3

[0117] 100 parts by weight of an acrylic emulsion solution (solid content 55%, ethyl acrylate-butyl acrylate-acrylonitrile copolymer (weight ratio 45:48:7)), fatty acid Ammonium-based surfactant (aqueous dispersion of ammonium stearate, solid content 33%) (surfactant A) 2 parts by weight, carboxybetaine-type amphoteric surfactant ("Amogen CB-H", Daiichi Kogyo Pharmaceutical company) (surfactant B) 2 parts by weight, oxazoline-based crosslinking agent ("EPOCROS WS-500" manufactured by Nippon Catalyst Co., Ltd., solid content 39%) 4 parts by weight, pigment (carbon black) (" NAF-5091 (manufactured by Dainichi Seika Kogyo Co., Ltd.) 1 part by weight, polyacrylic acid thickener (ethyl acrylate-acrylic acid copolymer (acrylic acid 20% by weight), solid content 28.7%) 0.6 part by weight, potassium titanate fiber ("Tismo D" manufactured by Otsuka Chemical Co., Ltd.) 30 parts by weight were stirred and mixed, and foamed. This foaming composition was coated on a PET (polyethylene tere...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap